This article provides a comprehensive guide on wiring three-pronged toggle switches. It elucidates the fundamental understanding of toggle switches, the purpose of each prong, and selection criteria for appropriate switches. Furthermore, it offers a detailed step-by-step guide to wiring, troubleshooting common issues, installation safety tips, and addresses frequently asked questions. This knowledge serves as an essential tool for those dedicated to assisting others in electrical tasks.

Introduction to Toggle Switches

A toggle switch, typically identified by its distinct lever that flips back and forth to control the flow of electricity within a circuit, stands as a critical component in various applications ranging from industrial machinery to everyday household items. Given their significant role in regulating electrical currents, they are available in an array of types tailored to specific functionalities and user requirements. A comprehensive understanding of these diverse types of toggle switches, each with unique properties and mechanism, is essential for their effective application across different domains.

What a toggle switch is and its common uses

Toggle switches, often found in many electronic devices, are manually operated electrical switches designed to control the flow of electricity through a circuit. They come in several types, including the basic on-off toggle switch which is one of the simplest type of toggle switch. The common uses for these mechanical switches include domestic appliances and industrial equipment where they provide a user-friendly interface for controlling electronic circuits. The success in executing tasks using these switches often depends on a basic toggle switch setup that ensures correct wiring and operation. This understanding allows those who desire to serve others effectively, to troubleshoot issues with electronic switches or install new ones as necessary.

The different types of toggle switches available in the market

Various models, each with distinct characteristics and functions, make up the diverse market of manually operated electrical circuit controllers. An extensive array of basic toggle switches are available, from LED toggle switches to panel mount switches.

In an article on toggle switch types, three primary classifications were identified:

- Double Pole Switch: This type has two input contacts and can control two separate circuits.

- Double Throw Switches: These have a single input contact but can connect alternately with one of two output contacts.

- LED Toggle Switch: Equipped with a built-in light indicator.

These options provide flexibility for individuals looking to serve others by ensuring specific needs are met through precise control over electricity flow within various environments or applications.

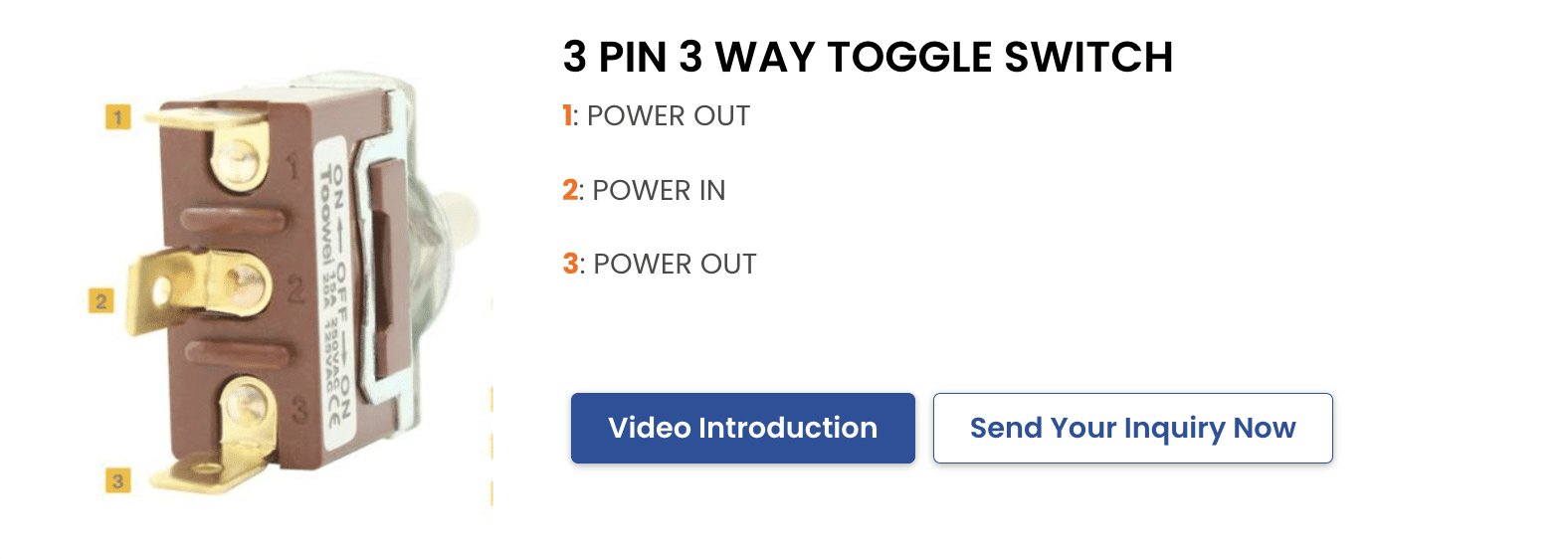

Understanding the 3 Prongs

In the subsequent discourse, attention will be focused on the three integral prongs of a toggle switch – commonly referred to as common, normally open, and normally closed. The exploration will not only define these components but also delve into the specific functions each prong serves in the operation of a toggle switch. This profound understanding is crucial to fully grasp the complex operation and wiring process associated with three-pronged toggle switches.

The three prongs found on a toggle switch (common, normally open, and normally closed

Three prongs typically found on a toggle switch encompass common, normally open, and normally closed terminals. These components play a vital role in the operation of a pin toggle switch.

- Common Terminal: This terminal connects to the power source and is essential for the successful operation of any electrical device.

- Normally Open Terminal: In its default state, this terminal does not have an electrical connection with the common terminal; however, it forms a circuit when the switch is toggled.

- Normally Closed Terminal: Contrary to the normally open terminal, this connection has an uninterrupted circuit with the common one in its resting state but disconnects upon activating the toggle switch.

Understanding these three prongs allows for precise wiring of a toggle switch with 3 prongs and effective service delivery to others.

Detailed description of the functions of each prong

Delving deeper into the functionality of each terminal sheds light on their respective roles in electrical operations. The pole toggle switch, often connected with a wire stripper, serves as the pathway for electrical connections. Its function is to direct current from one prong to another. Prong toggle switches play an integral role in managing the flow of electricity within circuits. They come in different forms: common, normally open, and normally closed, each performing a unique role that facilitates smooth electrical operations. A detailed description of the functions of each prong reveals intricate processes involved in making solder connections work efficiently. Thus, understanding these functionalities contributes significantly towards enhancing service delivery in the context of electrical repairs and installations.

Choosing the Right Toggle Switch

The ensuing discussion will delve into the critical factors to be considered when choosing a toggle switch, highlighting aspects such as current rating, voltage rating, and whether to opt for Single Pole Double Throw (SPDT) or Double Pole Double Throw (DPDT). Subsequently, the discourse will transition towards providing recommendations tailored to different applications. This exploration aims to equip readers with a comprehensive understanding of toggle switches, thereby enabling informed decision-making in their respective contexts.

Factors to consider when selecting a toggle switch (current rating, voltage rating, SPDT or DPDT, etc)

Important considerations in choosing a toggle switch include its current rating, voltage rating, and whether it is Single Pole Double Throw (SPDT) or Double Pole Double Throw (DPDT).

- Current Rating: This determines the maximum amount of electrical current that the on-off switch can handle. A higher current rating equates to better performance under heavier loads.

- Voltage Rating: This indicates the type of switch’s ability to withstand potential differences across its terminals without breakdown.

- SPDT/DPDT: These are types of switches that dictate how many circuits the switch can control.

The acquisition of this knowledge will enable individuals to efficiently serve others by making informed decisions about which toggle switches are most suitable for specific applications while ensuring safety and system longevity.

Recommendations for different applications

Recommendations for different applications of these devices hinge on understanding their functionality and choosing the appropriate one based on specific needs. The pin rocker switch, for instance, is used in various electrical applications due to its simple installation process. Similarly, three-prong toggle switches provide a safe and efficient alternative for controlling power to certain automotive equipment. Ensuring the correct use of wire nuts during the installation can guarantee secure connections and reduce potential safety risks. However, it must be acknowledged that careful consideration should be given when selecting between these switches since each has unique capabilities suitable for distinct situations. Therefore, thorough comprehension of these elements contributes significantly towards serving others optimally in any electrical application scenario.

Gathering the Necessary Tools and Materials

In the following discussion, attention will be directed towards essential tools and materials required for wiring a toggle switch. This includes an exploration of necessary tools such as wire cutters, wire strippers, and a soldering iron. Similarly, critical materials including the toggle switch itself, wires, solder and heat shrink tubing will also be enumerated upon to provide a comprehensive understanding of all elements needed for this task.

List of tools required for wiring a toggle switch (wire cutters, wire strippers, soldering iron, etc)

Acquiring the appropriate tools is a crucial first step in wiring a toggle switch with 3 prongs. This process necessitates specific items such as wire cutters, wire strippers, and a soldering iron.

The following list enumerates these essential tools:

- Wire Cutters: Necessary for cutting electric wires to the desired length.

- Wire Strippers: Employed to safely remove the insulating cover from the wires without causing damage.

- Soldering Iron: Used for joining wires together by melting solder onto them.

Understanding how each tool functions within the context of wiring a toggle switch allows one to serve others more effectively by providing clear instructions or performing the task competently and safely themselves. It is important to stress that safety precautions must be observed whenever handling these tools during any electrical project.

List of materials needed (toggle switch, wires, solder, heat shrink tubing, etc)

Essential materials for this electrical task include a tri-connection mechanism, conductors, fusible metal, and thermal insulation tubing. In simpler terms, these are known as 3-prong toggle switches, wires, solder, and heat shrink tubing respectively. These items are vital to ensure a safe and effective installation of the toggle switch. The table below presents each component with its corresponding function.

| Component | Function |

|---|---|

| 3-prong toggle switch | It acts as the control mechanism which directs the flow of current |

| Wires | They serve as conductors for electricity transfer |

| Solder | A fusible metal which creates secure electrical connections between components |

| Heat shrink Tubing | Provides thermal insulation for wires after soldering |

Appropriate installation instructions should be followed carefully to avoid any potential mishaps during the task.

Step-by-Step Wiring Guide

The forthcoming discussion will delve into the meticulous process of wiring a toggle switch with three prongs, initiated by outlining essential safety precautions prior to embarking on the wiring task. Consideration will be given to the preparation of both the toggle switch and wires before proceeding with their connection via soldering. The final stages of this intricate procedure involve insulating and securing connections for optimal function and longevity, thereby concluding this comprehensive guide.

Safety precautions before starting the wiring process

Prior to initiating the wiring process, certain safety precautions must be rigorously observed to prevent any electrical mishaps. These cautious steps ensure that both the individuals involved and the electrical equipment remain unharmed.

- Power Supply: Always disconnect from power supply before beginning the task. This reduces risk of electric shock.

- Grounding Wires: Install grounding wires appropriately as they can protect against electrical faults by providing a pathway for electric current to travel safely into the ground.

- Insulation Resistance: Regularly check insulation resistance of wires and devices; this will help avoid any unexpected conductivity which could be hazardous.

These measures promote safer environments when dealing with wiring tasks, thereby serving others not just through completed work but also through diligent adherence to safety protocols.

Preparing the Toggle Switch

Preparation of the electrical control mechanism involves careful selection and arrangement of its individual components to ensure efficient operation. This applies specifically when preparing the toggle switch, a common component used in many devices. The choice is often between 3-prong toggle switches due to their versatility and reliability in controlling electrical flow.

Next, device housing is considered as it provides protection for the electrical component while allowing easy access for maintenance or replacement. To wire a toggle switch, understanding of basic electrical principles is necessary, which includes knowledge on how to connect these common components securely. Furthermore, attention must be paid to preserving and enhancing functionality during installation. Therefore, meticulous preparation contributes significantly towards effective service delivery in any setting requiring use of such devices.

Preparing the Wires

Understanding the process of readying the conductive strands for connection is crucial in any electrical setup, as it influences both safety and performance.

- Initially, half-inch insulation must be removed from the negative wire, positive wire, and green ground wire to expose their respective conductive materials.

- Subsequently, each exposed end is crimped carefully onto a pigtail wire connector to ensure secure connectivity.

- Lastly, a critical part of this process involves verifying that all wires are properly connected and insulated before proceeding with the next steps.

Through these steps, an effective wiring setup can be achieved while ensuring safety protocols are upheld. This knowledge enables individuals to better serve others by maintaining consistent electrical performance and preventing potential hazards related to improper electrical connections.

Soldering the Wires to the Toggle Switch

After the meticulous preparation of wires, attention now shifts to soldering the wires to the toggle switch. This procedure is crucial in ensuring a stable and safe connection between the electrical device and the 3-prong toggle switches. It involves carefully attaching each prepared wire to its designated prong on the switch by melting solder onto them. The melted solder acts as a bonding agent, securing the wire firmly against each terminal of the toggle switch. This process not only establishes an electrically conductive link but also offers resistance against possible mechanical stress that could disrupt connections within an electrical device. Mastering this technique is of significant value for those with a passion for serving others through efficient and reliable electrical repair or installation services.

Insulating and Securing the Connections

Insulation and security of the connections form the next critical stage, providing safety measures to prevent electrical shocks and ensure longevity of the assembly. The process involves three key steps:

- Wrapping each prong-and-wire connection with insulating materials, such as heat-shrink tubing or electrical tape.

- Ensuring each connection is tightly secured to prevent accidental dislodging during use.

- Regularly inspecting these connections for damage or wear that could compromise their integrity.

This meticulous approach to insulating and securing connections in a toggle switch with 3 prongs ensures optimal functionality while prioritizing user safety. By diligently maintaining these integral parts, one serves not only oneself but also others who may interact with the system, thereby fostering a safer environment for all.

Testing the Wiring

The crucial significance of testing wiring prior to final installation is a topic that warrants in-depth discussion, as it has implications for both safety and efficiency. Ensuring the integrity of connections can prevent potential problems down the line, including system malfunctions or electrical fires. This discourse will also provide detailed instructions on executing a rudimentary continuity test using a multimeter, an essential tool in identifying breaks or shorts in the circuit.

Importance of testing the wiring before final installation

Ensuring proper functionality by testing the wiring prior to final installation provides a vital step in the process of connecting a three-prong toggle switch. The importance of testing cannot be overstated; it ensures safety, confirms correct connections and prevents potential damage to equipment.

- Safety: Testing the wiring before installing 3-prong toggle switches can prevent electrical shocks or fires caused by faulty wires or incorrect connections.

- Confirm Connections: Through this procedure, one can verify that each wire is correctly connected to its respective prong on the toggle switch.

- Prevent Damage: This proactive approach helps avoid equipment damage due to short circuits or overloads.

Instructions on how to perform a simple continuity test using a multimeter

Conducting a simple continuity test using a multimeter requires specific steps to accurately determine the presence of electrical flow between two points. This process is critical when trying to wire a toggle switch with 3 prongs, ensuring correct functioning upon installation.

| Steps | Tools | Process |

|---|---|---|

| Step 1 | Multimeter | Set to ‘Continuity’ mode |

| Step 2 | Toggle Switch & Wires | Attach one lead of the multimeter to each prong |

| Step 3 | Observations and Results | Note if there is an electrical flow |

This table provides concise instructions on how to perform a continuity test. It serves as guidance for those desiring to assist others in understanding the process effectively. Thus, performing such tests enhances safety and functionality in wiring tasks.

Troubleshooting Common Issues

The forthcoming discussion seeks to delve into the identification and troubleshooting of potential issues concerning toggle switch wiring. Close attention will be paid to commonly encountered complications, such as loose connections or faulty switches. The discourse will elucidate solutions for these issues, providing comprehensive guidance for effective problem resolution.

Identifying and troubleshooting potential problems with the toggle switch wiring

Identification and resolution of potential issues with the wiring of a three-prong toggle switch necessitates a comprehensive understanding of electrical circuits. In this regard,

- Identifying potential problems within the 3-prong toggle switches is paramount.

- Mastering the art of troubleshooting switch wiring can lead to efficient problem-solving.

- Understanding the function and connection points of switch terminals is crucial.

Common types of issues include loose connections, incorrect wiring, and faulty switches. By focusing on these areas, individuals can provide effective service to others by ensuring safe and functional use of 3-prong toggle switches. Overall, proficiency in identifying and resolving issues with toggle switch wiring will inevitably enhance one’s ability to serve others in an electrical capacity.

Providing solutions for issues such as loose connections or faulty switches

Addressing issues such as loose connections or faulty mechanisms involves implementing effective and proven solutions, ensuring the safe usage of electrical circuits. This particular discourse focuses on providing solutions for common problems encountered while wiring a 3-prong toggle switch.

| Issue | Cause | Solution |

|---|---|---|

| Loose connections | Inadequate securing of wires to the prongs | Tighten connections |

| Faulty switches | Damaged internal components in the toggle switch | Replace with new 3-prong toggle switch |

| Incorrect wiring | Misplacement of wires on prongs | Refer to wiring diagrams and correct placement |

These solutions serve as a guide for individuals facing similar situations, encouraging safer practices when dealing with electrical circuits. Understanding these potential issues is crucial in ensuring proper functionality of 3-prong toggle switches and minimizing risks associated with electricity usage.

Final Installation and Safety Tips

In the following discussion, emphasis will be placed on two crucial aspects of toggle switch installation. The first point of consideration, key point 8.1, involves the accurate and secure mounting of the toggle switch in its designated location; a step that is fundamental for effective operation. Concurrently, key point 8.2 will focus on essential safety guidelines for managing electrical wiring and manipulating toggle switches; these precautions are imperative to ensure both personal safety and equipment functionality.

Properly mounting the toggle switch in its intended location

Proper mounting of the toggle switch necessitates careful alignment in its intended location to ensure optimal functioning. This article about 3-prong toggle switches provides a comprehensive guide for properly mounting and wiring a toggle switch.

The process is broken down into three critical steps:

- Identify the intended location where the switch will be used, ensuring it provides easy access while maintaining safety considerations.

- Prepare the area for installation, which might involve creating an opening or securing a surface mount box.

- Install the 3-prong toggle switch by aligning it correctly with any pre-existing holes or guides, then secure it using appropriate hardware.

Safety tips for handling electrical wiring and working with toggle switches

Having established the process for securing 3-prong toggle switches, attention can now be directed towards the important issue of safety when handling electrical wiring and working with toggle switches. A fundamental understanding is necessary to avoid any mishaps during interaction with electrical appliances or while maintaining electricity steady. The process to wire a toggle switch with 3 prongs requires careful adherence to certain precautions. It is essential to disconnect all power sources before beginning any wiring work to prevent accidental electric shocks. Wearing rubber gloves and shoes provides additional insulation against potential risks. Furthermore, using insulated tools will assure further protection from electricity conduction. Lastly, making sure that no bare wires are left exposed after connections helps in preventing short circuits or sparks.

Frequently Asked Questions (FAQs)

In this discussion, the focus will be placed on several key considerations in the process of wiring a three-prong toggle switch. The first area to explore involves identifying which prong corresponds to power, ground, and load. Next, attention will be directed towards understanding if it is possible to wire a three-prong toggle switch into an existing circuit and common pitfalls that should be avoided during this process. Lastly, emphasis will also be given on essential safety guidelines that need adherence while performing the wiring operation.

How do I determine which prong is for power, ground, and load?

Identification of the specific prong for power, ground, and load necessitates a thorough understanding of the toggle switch’s wiring schematic. Three-prong toggle switches typically have a power terminal, a ground screw, and a load terminal.

- The power terminal: This is usually located at the top or side of the switch. It connects to the supply voltage to enable flow of electricity.

- The ground screw: Often found on one side or bottom of the switch, it helps in creating an effective return path for current.

- The load terminal: Directly connected with electrical appliances or loads.

Comprehension of these aspects is crucial while reading a wiring diagram for these switches. Serving others by ensuring their safety calls for meticulous attention to such details during installation processes.

Can I wire a toggle switch with 3 prongs into an existing circuit?

Integrating a three-terminal electrical control device into an existing circuit is indeed possible, but requires careful adherence to the appropriate wiring procedures and safety protocols. To wire a toggle switch with 3 prongs, specific steps should be followed. Initially, power must be disconnected from the existing circuit to ensure safety. Then, identify and connect the ground (usually green or bare copper wire) to one of the prong toggle switches’ terminals. The neutral wire in the circuit gets connected to another terminal on the pin toggle switch. Finally, for an existing three-way light switch, it’s essential to determine which wire controls what function before connecting it appropriately on the last terminal of the three-pronged device.

What are some common mistakes to avoid when wiring a toggle switch?

Common errors to evade during the installation of a three-terminal electrical control device involve incorrect connections, disregard for safety protocols, and faulty equipment use.

- Misuse of prong toggle switches: One of the common mistakes is the misconnection or misalignment of pair of switches. A pin toggle switch wiring diagram should always be consulted before starting any wiring procedure.

- Neglecting safety protocols: Safety cannot be compromised at any stage during installation process. Insulated gloves and eye protection are critical components for personal safety.

- Faulty usage of LED round rocker switch: The LED round rocker switch needs careful handling. Incorrectly connecting this component can lead to malfunctions or complete failure.

Understanding these pitfalls ensures more efficient installations with fewer problems in operation later on.

Are there any specific safety guidelines I should follow during the wiring process?

Adherence to specific safety guidelines during the electrical configuration process is crucial to ensure both personal protection and the correct functioning of the system. When wiring a toggle switch with 3 prongs, certain steps must be taken. Firstly, always disconnect power before initiating the wiring process. This prevents potential shock hazards. Safety goggles should also be worn to protect eyes from any unforeseen sparks or debris. In handling 3-prong toggle switches, care should be given not to force wires into terminals as this can result in damage or loose connections that could cause malfunctions later on. Furthermore, each wire’s insulation should remain intact except at termination points; stripped wires elsewhere may lead to short-circuits or fires if they contact other conductive materials during the wiring process.

Conclusion

In conclusion, a summary of the main points examined throughout this blog post is offered, providing an opportunity for the reinforcement of key concepts pertaining to toggle switch wiring. The practical application of these insights should be encouraged in order to foster confidence among readers in their ability to wire toggle switches effectively and efficiently. This integration of theory and practice not only enhances understanding but also promotes mastery of the skills required for successful implementation.

The key points

Summarizing the main concepts, it becomes clear that understanding the function of each prong is crucial in successfully wiring a three-pronged toggle switch. To accomplish this, the following steps are essential:

- Recognize that pin toggle switches often feature an on-off-on toggle switch mechanism.

- Identify and understand the roles of individual prongs in prong toggle switches.

- Wire appropriately to establish effective connections.

This recap of key points discussed throughout the blog post should reinforce knowledge regarding how to wire a toggle switch with 3 prongs. By mastering these elements, one can effectively serve others who may require assistance or guidance in handling similar tasks involving three-pronged toggle switches.

Apply newly acquired knowledge and wire toggle switches confidently

Transitioning from the recap of key points, focus is now shifted towards encouraging the application of newly acquired knowledge. Confidence in wiring toggle switches, particularly a toggle switch with 3 prongs, can be fostered by understanding and applying the information shared previously.

Consider the following table that outlines the steps to wire a toggle switch:

| Step | Description |

|---|---|

| 1 | Identify pin toggle switch |

| 2 | Prepare prong toggle switches |

| 3 | Connect wires to each prong |

| 4 | Test functionality |

| 5 | Troubleshoot if necessary |

This guide provides an efficient method for obtaining proficiency in this skill. The encouragement offered here is intended to inspire readers to apply their newly acquired knowledge and wire toggle switches confidently. In doing so, they will serve themselves and others effectively and competently.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd