A push button switch is a common electrical switch device used to control the on and off state of a circuit. The working principle of a push button switch can be simply summarized as switching the on and off state of a circuit according to the pressed or released state of the button. The following is a detailed explanation of the principle of a push button switch:

Working principle

Basic mechanism

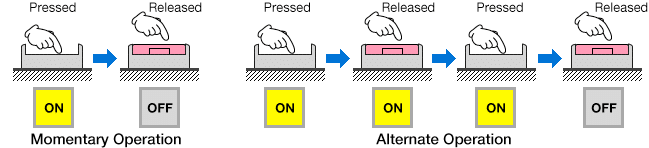

The push button switch controls the pressed and released state of the button to close and open the internal contacts. When the button is pressed, the trigger device closes the contacts to form a connected path, and the current can flow smoothly through the contacts to make the controlled device work. When the button is released, the trigger device opens the contacts, cutting off the current path, and the controlled device stops working.

Mechanical and electronic

The working principle of a push button switch can be realized in two ways: mechanical and electronic. Mechanical push button switches generally use mechanical contact to close and open the switch; while electronic push button switches use electronic components such as transistors, integrated circuits, etc. to realize the function of the switch.

Contact type

The push button switch usually contains normally open contacts and normally closed contacts. The normally open contact is in an open state when the button is not pressed, and is closed when it is pressed; the normally closed contact is the opposite, closed when not pressed, and open when pressed. This design allows the push button switch to implement complex control logic.

Structural composition

Push button switches are generally composed of buttons, contacts, trigger devices, and shells. The button is the part operated by the user, and the contact is the key component to achieve the circuit on and off. The trigger device is used to drive the contact action when the button is pressed or released, while the shell plays a role in protecting the internal structure and preventing misoperation.

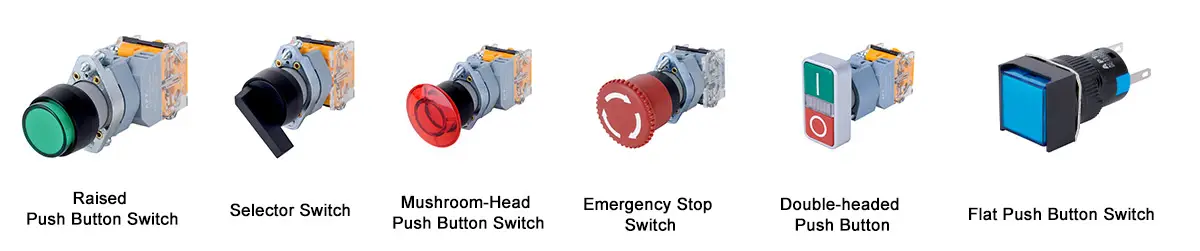

Types and applications

Push button switches can be divided into many types such as normally closed, normally open, and composite according to their functions and structures. In addition, there are special types such as self-locking push button switches and interlocking push button switches to meet specific control needs.

Push button switches are widely used in various electrical control systems, such as lighting control, electrical equipment control, automation equipment control, etc. They are usually used to send start or stop signals to control the operation of electrical equipment such as contactors, relays, and electromagnetic starters.

Precautions

When using a push button switch, you need to pay attention to the following points:

The push button switch must have a metal protective ring, and the ring must be higher than the button cap to prevent accidental touching of the button and causing malfunction. The button plate and button box on which the button is installed must be made of metal and connected to the main grounding bus of the machine.

In order to prevent misoperation, different marks are usually made on the buttons or painted with different colors to distinguish them. For example, a red button usually indicates danger or warning and is used for emergency stop; a green button indicates confirmation or agreement and is used to start the operation.

The status of the push button switch should be checked regularly, dirt and dust should be removed, and good contact of the contacts should be ensured. If poor contact or damage to the contacts is found, they should be replaced or repaired in time.

In summary, the push button switch realizes the on-off control of the circuit by controlling the pressing and releasing status of the button. Its working principle is simple and reliable, and it has a wide range of applications in the field of electrical control.

If you need a push button switch in your application, please contact our customer service. We will provide you with free samples and design the best solution for your application.