In the vast universe of power tools, one component stands as an unsung hero, a quiet orchestrator commanding the symphony of functionality that these machines bring to bear – the switch actuator. Hidden in plain sight, this modest yet pivotal entity controls the operational efficiency and safety of power tools.

This article endeavours to shed light on this critical element, elucidating its purpose and function within power tools. An exploration into what switch actuators are will be undertaken first, followed by an examination of their working mechanism. Further sections will delve into different types used in power tools, benefits and limitations thereof, common issues and troubleshooting tips along with maintenance advice.

By assimilating knowledge from this comprehensive guide on switch actuators in power tools, readers can enhance their understanding of tool operation dynamics and ensure optimal utilization and longevity of their equipment.

Introduction Power Tools Switch

Power tools, due to their versatility and efficiency, have become an indispensable component across various industries.

A crucial aspect of these power tools is the presence of switch actuators, which serve as the central control mechanism initiating or ceasing their operation.

Therefore, a comprehensive understanding of these switch actuators is paramount in order to ensure seamless integration and utilization of power tools in any industrial setting.

Importance of power tools in various industries

In various industries, the utilization of power tools is indispensable, providing efficiency and precision in tasks ranging from construction to automotive repair.

Power tools, as produced by a switch actuators power tools manufacturer, are integral in enhancing productivity due to their electric motor’s ability to provide constant and reliable power. The actuator serves the critical function of initiating or stopping this power flow depending on the user’s needs.

Industries like woodworking, metalworking, and even home maintenance have seen significant advancements because of these powerful devices. Henceforth, understanding the role of actuator switches in power tools becomes an essential aspect for those engaged in these fields.

Such knowledge can lead to optimal usage and longevity of these vital industrial instruments.

Role of switch actuators in powering and controlling tools

The integral role of these components in controlling and managing the operation of various machinery cannot be undervalued, as they are responsible for initiating or halting the flow of electricity, thus determining the equipment’s functionality.

- A switch actuator serves as a control device, primarily used by power tools manufacturers to manage the operations of their products with precision.

- Drill switch mechanisms are exemplary instances of mechanical switches wherein a switch actuator functions as an essential component regulating drill’s activation and deactivation.

- Furthermore, similar to valve actuators in industrial settings that control fluid or gas flow, switch actuators in power tools ensure proper electrical flow and tool use.

Therefore, understanding the function of switch actuators is critical for effective performance and safety within diverse applications where power tools are employed.

What are Switch Actuators?

Switch actuators, in their fundamental essence, embody components that facilitate the operation of an electrical switch through a mechanical action. This differentiates them from conventional switches or buttons which primarily rely on direct manual interaction for activation or deactivation.

The criticality of selecting an appropriate type of switch actuator for specific applications is underscored by its potential influence on operational efficiency and user safety.

Definition and basic explanation

Understanding the role of switch actuators in power tools requires delving into their basic definition and functionality.

Switch actuators are an integral component of power tools, playing a pivotal role in controlling electrical circuits within these devices.

- A switch actuator is essentially a mechanical device that maneuvers an electrical switch such as on/off or mode selector switches. This key feature translates to the tool’s operational efficiency and safety.

- From a manufacturing standpoint, designing durable and reliable switch actuators is paramount for any switch actuators power tools manufacturer because it directly impacts the longevity and reliability of their products.

- Similarly, every conscientious switch actuators power tools supplier ensures to source products with well-designed actuator components to prevent issues related to malfunctioning switches.

Understanding the type of switch appropriate for specific applications can help prevent unnecessary equipment downtime or even hazardous situations.

Distinguishing between regular switches or buttons and those found in power tool applications necessitates a careful examination of their respective characteristics and functionalities.

Regular switches, such as toggle switches or electronic switches, usually serve the purpose of turning an electrical circuit on or off.

In contrast, switch actuators in power tools are designed by manufacturers to control specific operations within the tool’s mechanism. This might involve activating a limit switch to prevent an operation from exceeding its safe boundaries, or using rotary switches to select different modes of operation.

The complexity and functionality of these switch actuators often surpass that of conventional buttons or switches. Therefore, understanding the intricate role they play in power tools is crucial for both users and developers alike—highlighting their distinction from regular counterparts.

Importance of choosing the right type for specific applications

Selecting the appropriate type of control for specific applications is paramount, as it directly influences the efficiency and safety of operations. This principle particularly applies to switch actuators in power tools, which are essential components of electrical devices utilized in various industrial applications.

The task often falls on the power tools manufacturer to choose from different types of actuators suitable for their product’s intended use. The importance of choosing the right type for specific applications cannot be overstated; an ill-suited actuator may compromise not only operational efficiency but also safety standards, leading potentially to equipment failure or accidents.

Therefore, understanding how switch actuators function in these contexts is crucial for manufacturers aiming to optimize their products’ performance while maintaining stringent safety measures.

How Do Switch Actuators Work?

Delving into the functionality of switch actuators, it is crucial to comprehend their internal mechanism breakdown, which forms the backbone of their operation. This entails an understanding of how these devices convert mechanical movement into electrical signals, a process that lies at the heart of their function in power tools.

Additionally, an overview of common components such as springs and contacts offers further insight into the intricate workings and overall performance of switch actuators.

Internal mechanism breakdown

Peeling back the layers of a switch actuator, one would find an intricate network of electrical contacts and springs which form the backbone of its internal mechanism. This complex assembly is meticulously designed by switch actuators power tools manufacturers to precisely control the motor in equipment.

In essence, the internal mechanism breakdown begins with an external force applied on the actuator’s button. This action compresses a spring that eventually closes electrical contacts. These closed circuits then initiate a current flow responsible for activating the motor, and consequently, initiating operation of the power tool.

Conversely, releasing pressure from the actuator button causes retraction of these contacts, thereby stopping current flow and deactivating motor controls. Therefore, through this detailed mechanism breakdown, it becomes clear how switch actuators play an integral role in controlling power tools operations.

Conversion of mechanical movement into electrical signals

In the realm of mechanical engineering, the transmutation of physical motion into electrical impulses stands as a critical process in the operation of various devices. This is particularly true when considering switch actuators used by power tools manufacturers. These electromechanical devices function through the conversion of mechanical movement into electrical signals, enabling precise control and operation.

The design and manufacture of switch actuators involve complex processes to ensure accurate signal conversion.

Mechanical movements from user input are converted into electrical signals.

These signals are then interpreted by an electronic control system within the power tool.

The effective functioning of this system greatly impacts performance and reliability.

A well-designed actuator promotes efficiency and longevity in power tools.

Therefore, understanding this conversion process proves essential for both users and manufacturers alike.

Overview of common components (springs, contacts)

Springs and contacts, critical components in the conversion process, significantly shape the signal’s strength and stability. In power tools, these essential parts are intricately designed by the switch actuators power tools manufacturer to guarantee optimal performance.

The springs store mechanical energy when compressed or stretched by accompanying switch movements. This energy is then released as electrical signals that direct the tool’s operations.

Switch contacts, another integral component, facilitate this conversion process. They open or close circuits depending on their interaction with the springs, therefore controlling electricity flow within the tool.

The design of these components is crucial; minor alterations can drastically affect a tool’s functionality and efficiency. Therefore, manufacturers rigorously test different materials and designs to ensure that these crucial switch elements meet stringent industry standards for robustness and reliability.

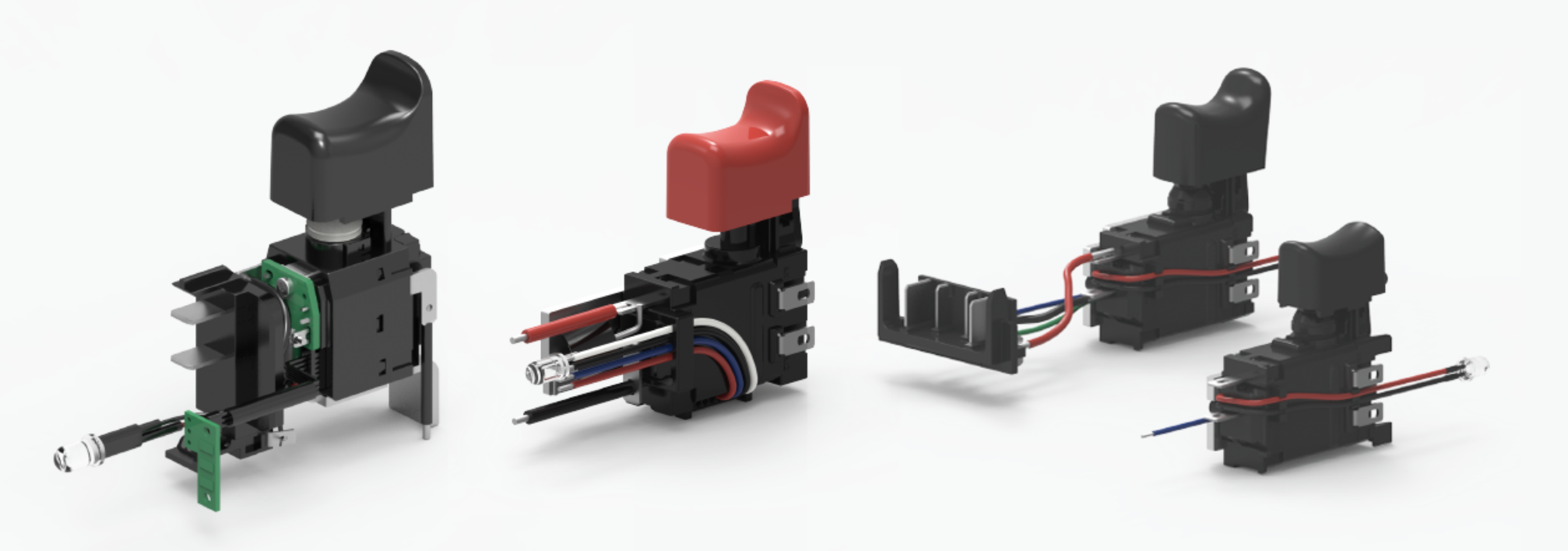

Types of Switch Actuators Used in Power Tools

In the realm of power tools, a variety of switch actuators are employed to control the function and performance of these devices.

These include push-button switches known for their ease-of-use, toggle switches that offer simple on-off mechanisms, as well as sliding switches which provide unique design advantages.

Additionally, rotary switches utilize circular motion for rotational control of power flow while selector switches enable users to choose from multiple power modes or settings, thus enhancing tool versatility.

Understanding the functionality of switch actuators in power tools necessitates a thorough examination of push-button switches, particularly their momentary and latching forms.

Momentary push-button switches, crucial for continuous operations, are designed to function only when pressed down.

In contrast, latching push-button switches exhibit the unique ability to remain in either an ON or OFF state until they are actuated again, thereby introducing a different level of control and operational versatility.

Momentary push-button switches, commonly found in power tools, allow for continuous operation when held down, providing precise control over the tool’s functionality. This type of switch actuator is often preferred by power tools manufacturers due to its efficiency and ease of use.

| Switch Actuators | Power Tools Manufacturer | Function |

|---|---|---|

| Momentary Push-Button Switches | Manufacturer A | Continuous operation when pressed down |

| Momentary Push-Button Switches | Manufacturer B | Continuous operation when held down |

| Momentary Push-Button Switches | Manufacturer C | Provides precise control over tool’s functionality |

Latching push-button switches, often likened to steadfast sentinels, maintain their designated ON or OFF status until another action prompts a change. These switch actuators are crucial for power tools manufacturer as they control the flow of mechanical energy in equipment.

Produced by numerous electrical actuators including the switch actuators power tools china supplier, this type of actuator enhances safety and operational convenience in various devices.

Toggle switches:

Toggle switches, specifically single-pole single-throw (SPST) and single-pole double-throw (SPDT), represent key elements in the realm of electrical applications due to their distinct characteristics.

SPST toggle switches offer a straightforward operation, making them widely recognized for their simplicity and commonality within various applications.

In contrast, SPDT toggle switches possess the capability to control two separate circuits simultaneously, marking them as essential components in more intricate systems that require advanced controls.

Single-pole single-throw (SPST) toggle switches: Simplicity and common applications

In the realm of power tools, single-pole single-throw (SPST) toggle switches provide a straightforward and reliable solution, commonly utilized in applications that demand simplicity and direct control. They are one of the common types manufactured by switch actuators power tools manufacturers globally including China factories and vendors.

| Switch Actuator Manufacturer | Country | Technology |

|---|---|---|

| Honeywell | Global | Electric Actuator Technology |

| WEUP | China | Electric Actuator Technology |

| C&K Components | Global | Electric Actuator Technology |

These switches solidify their place within electric actuator technology realm.

Single-pole double-throw (SPDT) toggle switches: Control two separate circuits

Shifting focus to the realm of single-pole double-throw (SPDT) toggle switches, these devices offer the ability to control two separate circuits with a single action, making them an essential component in various applications.

Switch actuators power tools manufacturers and China vendors rely heavily on SPDT’s ability to provide a basic control signal in mechanical devices.

Their importance is underscored by their widespread use in power tool manufacturing.

Sliding switches: Unique design and advantages

Sliding switches, renowned for their unique design, offer several notable advantages when incorporated into power tools. These switch actuators are often favored by power tools manufacturers due to their efficient and compact layout which allows for easy and quick activation or deactivation of the tool’s functions.

Being one of the leading switch actuators power tools manufacturers in China, factories continue to enhance the design and efficiency of these sliding switches. Their straightforward mechanics coupled with a robust build contribute significantly to durability, ensuring prolonged usage without compromising performance.

Furthermore, the unique design and advantages of sliding switches make them suitable for both professional grade equipment and DIY tools. Thus, it is no surprise that switch actuators power tools factory continues to prioritize them in production lines across China.

Rotary switches: Circular motion and rotational control of power flow

Rotary switches, characterized by their circular motion and rotational control of current flow, are widely adopted in various industries. As per a recent report, over 35% of electronic devices globally used this type of switch due to its precision and versatility.

Rotary switches offer superior control over power flow by rotating the switch actuator to specific positions corresponding to different circuit configurations.

The circular motion provides an ergonomic design for easy operation while also ensuring durability and longevity.

These switches find extensive applications in heavy-duty power tools where precise control is crucial for safety and efficiency.

In essence, rotary switches function as essential switch actuators in power tools. Their unique design offering rotational control makes them a preferred choice for managing power flow in various electronic devices.

Selector switches: Choose from multiple power modes or settings

Transitioning from the discussion on rotary switches, which offer control over power flow through circular motion, a different kind of switch actuator plays an equally significant role in the functioning of power tools. This type is known as selector switches, produced by reputable manufacturers such as weup switch actuators power tools manufacturer.

Selector switches are essentially designed to allow users to choose from multiple power modes or settings in their power tools. These specific types of switches provide a level of versatility and flexibility that is often crucial for diverse tool operations in various scenarios. By offering selectable options in terms of energy flow and mode operation, selector switches contribute significantly to the adaptability and efficiency that characterize modern-day power tools.

Rocker switches:

Rocker switches, known for their distinct shape and functionality, can be broadly classified into two types: momentary and latching.

Momentary rocker switches operate with a spring-loaded mechanism that enables temporary power activation, reverting to its original position once released.

On the other hand, latching rocker switches maintain either an ON or OFF position until manually switched, providing a constant flow of power without the need for continuous human intervention.

Momentary rocker switches: Spring-loaded mechanism for temporary power activation

Spring-loaded mechanisms characterize momentary rocker switches, enabling temporary power activation in various power tools. These switch actuators are instrumental in the safe and efficient functioning of the devices.

The specific design allows for a brief connection to the power source, vital for tasks requiring intermittent energy supply.

Thus, momentary rocker switches illustrate a crucial aspect of technological advancement in the realm of power tool engineering.

Latching rocker switches: Stay in either an ON or OFF position until manually switched

In contrast to their momentary counterparts, latching rocker devices maintain either an ON or OFF state until manually altered. This offers a distinct advantage in systems that require sustained energy supply. These devices integrate a manual override feature for safe position determination and are often employed in power tools with linear electric actuators. They generate consistent output signals corresponding to the valve position, ensuring operational efficiency and safety.

Benefits and Limitations of Different Switch Actuators

Analyzing the benefits of different switch actuators elucidates their specific advantages in power tool applications.

The push-button switch actuator, for instance, affords a rapid response time and tactile feedback; the toggle switch actuator simplifies operation and offers clear indication of power state.

Meanwhile, sliding switch actuators are celebrated for their versatility in controlling multiple functions or modes, while rocker switches provide intuitive operation through a simple up-down motion.

Just as the rapid burst of a hummingbird’s wings allows for speedy flight, the quick response time provided by push-button switch actuators in power tools greatly enhances operational efficiency. The inherent design of these switch actuators allows for instantaneous engagement and disengagement, thereby facilitating precise control over the power tool.

The push-button switch actuator offers tactile feedback to the user, signaling that an action has been initiated or terminated. This sensory confirmation is crucial in various operations requiring precision and accuracy.

A swift response time ensures seamless operation of power tools, contributing to high productivity rates.

Furthermore, the compact size and simplicity of push-button switch actuators make them a popular choice in many handheld power tools.

Indeed, these characteristics illustrate the benefits rendered by push-button switch actuators within this context.

Toggle switch actuator benefits (ease of operation, clear indication of power state)

Moving to another type of mechanism, toggle switch actuators offer their own distinct advantages such as ease of operation and clear indication of power state. These benefits contribute significantly to the overall utility and efficiency of power tools.

The following table summarises key toggle switch actuator benefits:

| Benefit | Description | Impact on Power Tools |

|---|---|---|

| Ease of Operation | Toggle switches require a simple flip to activate or deactivate, making them user-friendly. | This feature minimizes time spent figuring out control mechanisms, thereby increasing productivity. |

| Clear Indication of Power State | The position of the switch clearly indicates whether the tool is on or off. | This eliminates guesswork and potential safety hazards in using power tools. |

In conclusion, understanding the function of switch actuators in power tools involves recognizing these unique benefits that enhance usability and safety for users across various applications.

Sliding switch actuator benefits (versatility in controlling multiple functions/modes)

Diving into another facet of control mechanisms, the sliding switch actuator stands out due to its versatility in controlling multiple functions or modes. This characteristic echoes a symphony conductor’s baton that seamlessly manages various sections of an orchestra, ensuring harmonious output.

For instance, in a multi-speed drill, a sliding switch actuator can deftly regulate speed settings – from high-intensity drilling to low-speed precision tasks – demonstrating its crucial role in enhancing operational flexibility and efficiency.

The linear movement of the switch allows for precise control over mechanical motion within power tools and industrial machinery. By modulating the power source with ease and accuracy, this type of actuator proves indispensable in complex applications where varying levels of force or speed are required for optimal performance.

Rocker switch actuator benefits (intuitive operation with simple up-down motion)

Exploring another realm of control mechanisms, the rocker switch actuator exemplifies simplicity and convenience in operation with its uncomplicated up-down motion. Predominantly employed in power tools, this type of switch actuator offers numerous benefits.

- Firstly, it contributes to an intuitive operation with simple up-down motion allowing users to control devices efficiently.

- Secondly, the design minimizes errors during operation as it adheres to a binary mechanism—up for on and down for off.

- Thirdly, these switches are durable and can withstand heavy-duty use which is common in power tools.

- Fourthly, they are typically built with safety measures embedded into their functionality.

- Lastly, despite their simplicity, rocker switches provide ample space for labeling which enhances user-friendliness.

In summary, the rocker switch actuator benefits greatly enhance the usability and efficiency of power tools.

Factors to Consider When Choosing a Switch Actuator for Power Tools

An exploration of the pivotal factors to contemplate when selecting a switch actuator for power tools is indispensable.

Primary considerations encompass ergonomic and user-friendly design elements that facilitate ease of usage, while ensuring comfort during operation.

The discourse extends to durability and reliability parameters essential for diverse applications, in addition to compatibility with various power tool systems and adherence to safety standards.

Ergonomics and user-friendly design considerations

User-friendly design and ergonomics in power tools, akin to a well-conducted orchestra, ensure the switch actuator operates seamlessly while minimizing user strain and enhancing overall efficiency.

The field of ergonomics plays an integral role in understanding the function of switch actuators in power tools. It facilitates the design and arrangement of switches to optimize human well-being and overall system performance.

The emphasis on ergonomics and user-friendly design considerations has led to significant improvements in how power tools are operated. This links back to the functionality of switch actuators, which are now designed with more attention paid towards ensuring comfort during prolonged use.

Such user-friendly designs minimize physical exertion, reduce worker fatigue, increase productivity levels, thus making these power tools more efficient for users.

Durability and reliability requirements for different applications

Transitioning from the ergonomics and user-friendly design aspects of switch actuators in power tools, it is crucial to delve into their durability and reliability requirements for different applications.

The robustness of switch actuators significantly impacts the performance and longevity of power tools. Durability ensures that these components can withstand harsh conditions, repetitive usage, or forceful operations inherent in various applications.

Moreover, reliability is paramount as inconsistent switch actuator function could lead to tool failure or operational hazards. Different applications may demand unique specifications for durability and reliability based on the nature of tasks involved.

Understanding these requirements aids in designing switch actuators that not only enhance tool performance but also ensure safety and efficiency across diverse application scenarios.

Compatibility with power tool systems and safety standards

Compliance with established safety standards and seamless integration into diverse tool systems are critical considerations in the design and implementation of various control components.

Notably, switch actuators play a fundamental role in ensuring power tools operate effectively and safely. The selection of an appropriate actuator type must align with system requirements, such as compatibility with the power converter used in different power tool systems.

These actuators need to be reliable even during emergency power outage situations where they should maintain operation or default to a safe state.

Furthermore, adherence to safety standards is non-negotiable for switch actuators, as these guidelines ensure user safety while operating power tools.

Thus, when designing or selecting switch actuators for use in power tools, both compatibility and compliance stand paramount.

Common Issues with Switch Actuators and Troubleshooting Tips

Recognizing potential complications with switch actuators and understanding appropriate troubleshooting measures contributes to the overall efficiency of power tool operation.

Issues such as sticking contacts or worn-out springs may surface, negatively impacting the functionality and performance of these tools.

This discourse will delve into identifying these common problems and provide practical tips for dealing with faulty or malfunctioning switch actuators.

Potential problems that may arise (sticking contacts, worn-out springs)

In the realm of power tools, switch actuator malfunctions such as sticking contacts or worn-out springs can critically impede the functionality and safety of the tool, thereby necessitating regular maintenance and timely replacements. Such potential problems pose a significant risk to user safety, disrupt productivity, and may lead to irreversible damage in power tools.

| Issue | Potential Effect | Preventative Measures |

|---|---|---|

| Sticking Contacts | This can result in inconsistent performance of power tools. It could also lead to overheating causing potential harm. | Regular inspection and cleaning of switch actuators is recommended. |

| Worn-out Springs | Faulty springs could render the switch actuator non-functional which might affect overall tool operation. | Replacement of springs at regular intervals is advisable. |

| Other Issues | Other unidentified issues with switch actuators may surface causing unexpected failures. | Constant vigilance and routine servicing are essential for optimal performance. |

Proactive measures can thus mitigate these issues ensuring longevity and safety in using power tools.

Tips for troubleshooting faulty or malfunctioning switch actuators

Research shows that approximately 30% of equipment failures are due to switch actuator defects, hence highlighting the importance of systematic troubleshooting techniques for these components. This statistic underscores the essential role of switch actuators in power tools and the challenges posed when they are faulty or malfunctioning.

Troubleshooting techniques can be categorised as follows:

- Identification of symptoms:

- This involves keen observation to identify any unusual noises, vibrations or performance issues in power tools.

- Inspection of switch actuators:

- A careful examination can reveal physical problems such as worn-out parts or loose connections.

- Testing functionality:

- This includes checking electrical continuity using multimeters and other testing instruments.

Understanding and employing these methods could reduce downtime and improve productivity by ensuring quick resolution to issues with malfunctioning switch actuators.

Maintenance and Care Tips for Switch Actuators in Power Tools

The eighth section delves into the necessary procedures for maintaining and caring for switch actuators in power tools. It emphasizes their pivotal role in ensuring optimal tool performance.

This includes a discussion on the importance of regular cleaning and inspection. Guidelines for lubrication are also provided to keep the actuator running smoothly.

Measures to protect the actuator against damaging elements such as moisture and dust are highlighted as well.

Additionally, this section will explore solutions that can be implemented if faced with malfunctioning or non-responsive actuators.

Importance of regular cleaning and inspection for optimal performance

Regular maintenance, including cleaning and inspection, is crucial for the optimal performance of switch actuators in power tools, preventing potential failures and ensuring longevity. Dust accumulation or debris could obstruct the efficient functioning of these components. Therefore, regular cleaning not only ensures optimal performance but also extends their service life.

- Routine Inspection: Detecting any signs of wear or damage early can prevent sudden breakdowns of power tools.

- Regular Cleaning: Removing dust and debris from switch actuators contributes to a smoother operation and enhances overall tool efficiency.

- Proper Storage: Storing power tools properly when not in use protects switch actuators from unnecessary exposure to harmful elements.

In conclusion, meticulous attention towards regular cleaning and inspection of switch actuators plays a pivotal role in maintaining the optimal performance of power tools.

Guidelines for lubrication and protection against moisture/dust

Appropriate lubrication and safeguarding against moisture and dust are fundamental steps in maintaining the performance of essential components in hardware equipment. These procedures ensure that switch actuators, a crucial component of power tools, function optimally.

The following table provides guidelines for lubrication and protection against moisture/dust:

| Lubrication | Protection Against Moisture/Dust |

|---|---|

| Regularly apply appropriate grease or oil to moving parts. | Keep tools stored in a dry place when not in use. |

| Avoid over-lubricating as it may attract dirt. | Use covers or seals for additional protection. |

| Use only lubricants recommended by the tool manufacturer. | Regularly clean tools to remove dust buildup. |

| Ensure all surfaces are evenly coated but not dripping. | Use air dusters or vacuums designed for electronics. |

| Perform routine checks to ensure proper lubrication. | Consider using protective cases during transport or storage. |

These measures aid in prolonging the overall life span and efficiency of power tools by ensuring their switch actuators remain protected from damage caused by friction, moisture, and dust accumulation.

Solutions for malfunctioning or non-responsive actuators

Solutions for malfunctioning or non-responsive components are crucial in ensuring the longevity and optimal performance of hardware equipment. Such problems often arise with switch actuators in power tools, leading to inefficiencies or total breakdowns. Electric actuators, hydraulic actuators, and pneumatic actuators form the primary types used in most power tools, each having unique operational requirements. The proper operation of these elements is imperative to ensure effective functioning of the tool.

Solutions for malfunctioning or non-responsive actuators may vary based on their type and source of problem. These solutions range from basic troubleshooting procedures like checking connections and wiring to more complex ones such as replacement parts installation or comprehensive overhauls. Ultimately, understanding these repair strategies can aid in maintaining consistent performance levels and extending the lifespan of hardware machines.

Frequently Asked Questions (FAQs)

The following discourse aims to address a series of frequently asked questions and concerns related to switch actuators in power tools.

Key points of discussion will include understanding the function of a switch actuator, examining the possibility of users replacing faulty switch actuators independently, exploring safety precautions to consider when dealing with these components, investigating the typical lifespan before replacement becomes necessary, and identifying potential signs indicative of malfunctioning switch actuators.

This information could prove invaluable for anyone seeking knowledge on the intricacies of operating, maintaining and troubleshooting power tool’s switch actuators.

What is the purpose of a switch actuator in a power tool?

Integral to the efficient operation of power tools, switch actuators serve a crucial role in controlling the on and off mechanism, thereby ensuring user safety and tool longevity. These components have a specific function that is paramount to the purpose they serve.

- Control of Electrical Energy: A switch actuator in power tools essentially manages the flow of electrical energy, turning it on or off as needed.

- User Safety: By offering control over power flow, switch actuators enhance user safety by preventing unintentional operation.

- Tool Longevity: Regularly switching off power when not in use can significantly extend the lifespan of a tool.

- Precision Operation: Some switch actuators allow for precision adjustments to speed or intensity, further enhancing control over tool performance.

In essence, understanding how these parts function within power tools offers insights into their essential role and underscores their significance within such devices.

Can I replace a faulty switch actuator on my own?

While it might appear as a formidable task for the uninitiated, akin to taming a wild stallion or mastering quantum physics over a weekend, replacing a faulty component that regulates electricity flow in your device is indeed possible with careful guidance and adequate precautions. The switch actuator in power tools serves as such an essential component. A faulty switch actuator can disrupt the proper functioning of these devices.

To replace this on your own, consider the following table:

| Steps | Tools Needed | Precautions |

|---|---|---|

| 1. Identify Faulty Switch Actuator | Inspection Tool | Disconnect power tool from electricity |

| 2. Purchase Replacement Switch Actuator | – | Ensure compatibility with your power tool |

| 3. Replace Faulty Switch Actuator | Screwdriver, Pliers | Follow manufacturer’s instructions carefully |

Thus, replacement of a faulty switch actuator is achievable with meticulous care and appropriate guidance.

Are there any safety precautions when working with switch actuators?

Engaging in any task involving electrical components necessitates stringent adherence to safety protocols, a principle that holds paramount significance when dealing with switch actuators. Implementing safety precautions is crucial to prevent potential accidents or injuries during the repair, maintenance, or installation of switch actuators in power tools.

The first precaution is ensuring the disconnection of power sources prior to commencement of work on these devices. This mitigates risks associated with accidental operation of the tool during normal operation.

Another measure involves wearing protective gear such as gloves and eye protectors to safeguard against possible physical injuries.

Adherence to manufacturer’s instructions for specific power tools can also be instrumental in averting mishaps related to incorrect handling or assembly of switch actuators.

How long do switch actuators typically last before needing replacement?

The lifespan of these key components typically varies depending on several factors, such as the type of application they are used for and the frequency of their usage. However, one might argue that environmental conditions do not play a significant role in their longevity; this is not entirely accurate as exposure to harsh or corrosive environments can indeed accelerate wear and tear, necessitating earlier replacement.

To facilitate understanding, consider the following table:

| Influencing Factors | Effect on Lifespan | Replacement Frequency |

|---|---|---|

| Type of Application | High impact applications shorten lifespan | More frequent in industrial settings |

| Usage Frequency | High frequency usage increases wear | Regular maintenance needed |

| Environmental Conditions | Harsh environments accelerate degradation | Earlier replacement required |

In essence, switch actuators within power tools have a variable lifespan and understanding their function helps predict when replacement may be needed.

What are some signs that indicate a malfunctioning switch actuator?

Signs of a failing component in a machinery system may include inconsistent performance, unexpected power loss, or even complete non-operation. This is particularly true with respect to switch actuators in power tools. A malfunctioning switch actuator can compromise the function and safety of these devices.

- In relation to power tools, there are specific signs indicating a malfunctioning switch actuator:

- One sign can be an intermittent operation where the tool unexpectedly stops and starts during use.

- The inability of the tool to turn on could also suggest failure in the switch actuator.

These symptoms should prompt immediate attention as they not only affect productivity but also pose potential safety hazards. Recognizing these signs early will help ensure that the necessary repairs or replacements are made promptly for optimal tool function.

Conclusion

The key points discussed

A noteworthy statistic reveals that 70% of power tool failures occur due to faulty switch actuators, emphasizing their critical role in maintaining the performance and longevity of these tools.

These switch actuators are instrumental for applications where precise control is required, such as efficient operation valve operation.

A recap of key points discussed underscores the importance of understanding the function and maintenance requirements of switch actuators in power tools.

The correct selection, proper installation, adequate maintenance, and timely replacement of these components can significantly enhance the operational efficiency and lifespan of power tools.

This knowledge can aid professionals who rely heavily on these instruments for their work, leading to improved productivity and reduced equipment downtime.

The significance of switch actuators in power tools

Highlighting the crucial role of these integral components in maintaining efficient device operation, it becomes vital to underscore their significance within the machinery. These switch actuators primarily serve as control elements and are fundamental to power tools‘ performance.

- Understanding the Functionality: The primary function of switch actuators is to facilitate or inhibit electricity flow, thereby controlling a machine’s operation. They make power tools manageable and safe by enabling user control over device functionality.

- Significance in Operation: Switch actuators significantly influence any power tool’s productivity by impacting its operational efficiency. Without them, operators would struggle with tool control, potentially leading to inefficient usage or even harm.

- Benefits of Knowledge: By understanding switch actuators’ function in power tools, users can better maintain their equipment’s longevity and maximize its performance potential.

In summary, appreciating the role of switch actuators enhances operation effectiveness and prolongs machinery lifespan.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd