Angle grinders are versatile power tools that can be used for a wide range of tasks in construction, metalworking, and DIY projects. These tools are popular because of their ability to perform various cutting, grinding, and polishing tasks quickly and efficiently. However, like any power tool, angle grinders can be dangerous if not used correctly or if the user is not aware of how they function.

One essential aspect of an angle grinder that users must understand is its power tool switch. The switch controls the operation of the tool and helps prevent accidents by allowing users to turn off the device quickly when necessary.

In this article, we will provide an overview of what angle grinders are and why understanding their power tool switch is crucial for safe usage. We will also discuss the anatomy of a power tool switch, different types available in angle grinders, how they work, factors to consider when choosing one for your needs and common issues associated with them.

Additionally, we will offer safety tips so you can use your angle grinder safely and effectively every time you need it.

Introduction Power Tool Switch

Angle grinders are powerful tools commonly used in various industries such as construction and metalworking. They are versatile, efficient, and can be used for a wide range of applications. However, due to their power and speed, angle grinders can be dangerous if not handled properly.

Therefore, it is important to understand the tool’s safety features and specifically its power switch to prevent accidents while using it.

Briefly introduce the topic and its importance in using angle grinders safely.

Understanding the proper use of an angle grinder’s power tool switch is crucial for safely operating this powerful tool. The power tool switch is a safety feature that controls the operation of the angle grinder, and it can help reduce the risk of accidents or injuries when used correctly.

To fully appreciate the importance of understanding how to use an angle grinder’s power tool switch, consider these five points:

- The power tool switch allows you to turn on and off the angle grinder quickly and easily.

- A paddle switch is a common type of power tool switch found on many angle grinders.

- Using a paddle switch requires you to hold down a button or lever with your thumb or finger while using your other hand to grip the handle.

- Releasing pressure on the paddle switch will stop the rotation of the grinding wheel almost immediately.

- Properly using an angle grinder’s power tool switch can help prevent accidental start-ups, which could lead to serious injury.

By taking time to understand how an angle grinder’s power tool switch works, you can operate this powerful machine more safely and effectively. Remember that safety should always be your top priority when working with any type of power tools.

Grab the reader’s attention with an interesting anecdote or statistic.

With over 25,000 angle grinder injuries reported annually in the United States alone, it is crucial to recognize the importance of mastering all aspects of this powerful tool. Among the various components of an angle grinder, its power tool switch plays a critical role in determining how safe and efficient the device can be.

The power tool switch is primarily responsible for turning on and off the machine’s motor and regulating its speed. It also helps control other features such as spindle lock, safety guard, and disc replacement.

Angle grinders’ power tool switches are usually manufactured by several companies worldwide that specialize in producing electrical equipment for industrial use. The manufacturer or supplier usually designs these switches to meet specific requirements based on the type of angle grinder they will be used with.

Understanding how these switches work is essential as it can help prevent accidents from occurring while using an angle grinder. Basic knowledge about angle grinder switches includes identifying their location, understanding their functions, and following safety tips when operating them.

By familiarizing oneself with these basics, one can ensure that they operate the device safely and avoid any potential hazards associated with using an angle grinder.

What is an Angle Grinder?

An angle grinder is a handheld power tool commonly used for cutting, grinding and polishing tasks in various industries. Its purpose is to remove material from a workpiece by using a rotating abrasive disc that spins at high speeds.

This versatile tool has several components, including the power tool switch, which controls the on/off function of the grinder and allows users to adjust speed settings based on their specific needs.

What an angle grinder is, its purpose, and common uses.

Angle grinders are versatile power tools used for grinding, cutting, and polishing various materials such as metal, concrete, and stone. They consist of a motor that drives a spinning abrasive disc or blade. The angle grinder is characterized by its small size and ability to be handheld. It can be operated using one or two hands depending on the size of the tool.

Angle grinders come in different sizes ranging from 4-1/2 inch to 9-inch blades. They also have different handle designs made for specific applications. Some angle grinders have a side handle while others have a top handle designed for vertical use. The choice of handle design depends on the application and user preference. Angle grinders are commonly used in construction sites, workshops, and homes due to their versatility in handling different materials. The table below shows common uses of angle grinders:

| Material | Application |

|---|---|

| Metal | Cutting |

| Concrete | Grinding |

| Stone | Polishing |

| Wood | Carving |

An angle grinder is a powerful tool that has become an essential part of any workshop or construction site due to its versatility in handling different materials. Whether you need to cut metal pipes or polish stones, an angle grinder provides the perfect solution with its range of blades and handles designed for specific applications. Understanding how to operate an angle grinder safely is crucial as it has several safety risks associated with improper use such as kickback injuries caused by binding during operation or accidental activation through the power tool switch.

The Essential Role of an Angle Grinder’s Power Tool Switch

One of the key components of this versatile power tool is its power tool switch. The angle grinders power tool switch is an essential safety feature that controls its operation. It is responsible for starting and stopping the grinder, which makes it a crucial component in handling the device. Without it, users would not be able to control the pressure or attachments used with their angle grinder effectively.

The power button on an angle grinder’s power tool switch comes with several safety features to prevent accidental start-ups. For instance, it requires more than just a push of a button to activate. Users need to apply consistent pressure until they hear a click sound before the device starts working.

Moreover, if there are any issues or malfunctions with this component, users should immediately take steps to correct them as they can pose significant risks when using an angle grinder.

In conclusion, understanding how an angle grinders’ power tool switch operates and its various safety features is crucial for safe usage and effective performance of this versatile handheld device.

Importance of Understanding the Power Tool Switch

Understanding the power tool switch in angle grinders is crucial for safe and effective usage of this powerful tool. The significance lies in being able to control the speed and direction of the grinder’s disc, which can be dangerous if not handled properly.

Improper usage or mishandling of the switch can lead to serious injuries such as lacerations, burns, or even amputations. Therefore, it is important to follow proper safety procedures while using an angle grinder and understand how its power tool switch works.

The significance of understanding how the power tool switch works in angle grinders.

Comprehension of the power tool switch in angle grinders is crucial for safe and effective use of this equipment. Angle grinders are widely used for cutting, grinding, and polishing tasks due to their versatility and powerful motors. However, these tools can also be hazardous if not operated correctly.

Understanding the power tool switch in angle grinders is essential as it allows users to control the machine’s speed, turn it on or off, and activate its safety features. To comprehend the operation of an angle grinder’s power tool switch fully, users must be aware of its significance in terms of safety features.

The following bullet list highlights some important aspects that make understanding the power tool switch significant:

- It enables users to prevent accidental start-up by locking the machine’s trigger when not in use.

- It allows quick and efficient adjustments to the speed settings based on different applications.

- It activates emergency stop mechanisms that shut down the device instantly in case of any mishaps.

Overall, understanding how an angle grinder’s power tool switch works is crucial for maximizing efficiency while ensuring user safety. By comprehending how different modes work and activating safety mechanisms available through this feature, professionals can perform their tasks more efficiently without compromising their well-being or causing damage to property.

Safety concerns and potential risks associated with improper usage.

Improper usage of the switch in angle grinders can result in severe injuries and property damage, making it crucial for users to be aware of safety concerns and potential risks associated with its operation. One common type of power tool switch found on angle grinders is the lock-on paddle switch. This type of switch allows users to keep the grinder running without continuously holding down the trigger. However, this convenience can also pose a significant risk if the tool is accidentally dropped or snagged on something while still active.

Another concern with using an angle grinder’s power tool switch is related to eye safety. The high RPMs (revolutions per minute) generated by these tools can cause debris to fly off at high velocities, potentially causing injury or blindness if it comes into contact with unprotected eyes. Therefore, it is vital that users wear appropriate personal protective equipment such as safety glasses when operating an angle grinder. Additionally, proper training and education are necessary before using any power tool to ensure safe operation and reduce the risk of accidents.

| Potential Risk | Safety Precaution |

|---|---|

| Injury from accidental activation | Do not leave a powered-on grinder unattended; always turn off when not in use |

| Flying debris | Wear appropriate personal protective equipment such as safety glasses |

| Electrical hazards | Inspect cords for damage before use; keep electrical connections dry and away from water sources |

Anatomy of a Power Tool Switch

This section will discuss the anatomy of a power tool switch, specifically focusing on the angle grinder’s switch. The discussion will break down the different parts and mechanisms that make up the switch, including:

4.1: Its various components

4.2: How each component contributes to its overall functionality.

By examining these details, readers can gain a deeper understanding of how power tool switches work and why it is important to understand their inner workings for safe and effective use.

Break down the different parts and mechanisms of an angle grinder’s power tool switch.

To analyze the various components and mechanisms of an angle grinder’s power tool switch, it is important to take a closer look at its intricate design and how they all work in tandem.

The angle grinder’s power tool switch is composed of several parts that are carefully crafted to ensure safety and efficiency during operation. Here are some of the key components:

- Switch mechanism: This is the heart of the power tool switch, responsible for turning on or off the machine. It consists of a spring-loaded lever that moves up and down when pressed by the user.

- Contacts: These are two metal plates that come into contact with each other when the switch is turned on, allowing electricity to flow through the machine.

- Housing: This is where all the components are housed, protecting them from external damage. The housing also provides a comfortable grip for users.

Manufacturers such as China factory or China supplier pay close attention to every detail in designing these parts to ensure their durability and reliability.

By understanding how each component works together, users can operate their angle grinders safely and effectively.

Understanding an angle grinder’s power tool switch requires breaking down its different parts and mechanisms. Manufacturers invest time in designing these switches with precision to guarantee safe usage for consumers.

With this knowledge, users can confidently operate their machines without compromising their safety or performance.

How each component contributes to its functionality.

In the previous subtopic, we discussed the different parts and mechanisms of an angle grinder’s power tool switch. It is important to understand each component in order to properly operate the tool and avoid any potential hazards.

In this section, we will delve deeper into how each of these components contributes to the functionality of an angle grinder’s power tool switch.

The speed control function is one of the most important features of an angle grinder’s power tool switch. This allows users to adjust the speed of the tool based on their specific needs, which can help improve precision and efficiency during use.

Additionally, many manufacturers include additional safety features such as a guard that covers part of the disc during operation, preventing debris from flying out and potentially causing harm to nearby individuals or objects.

Understanding how these different components work together can help users safely operate their angle grinders while also maximizing its capabilities.

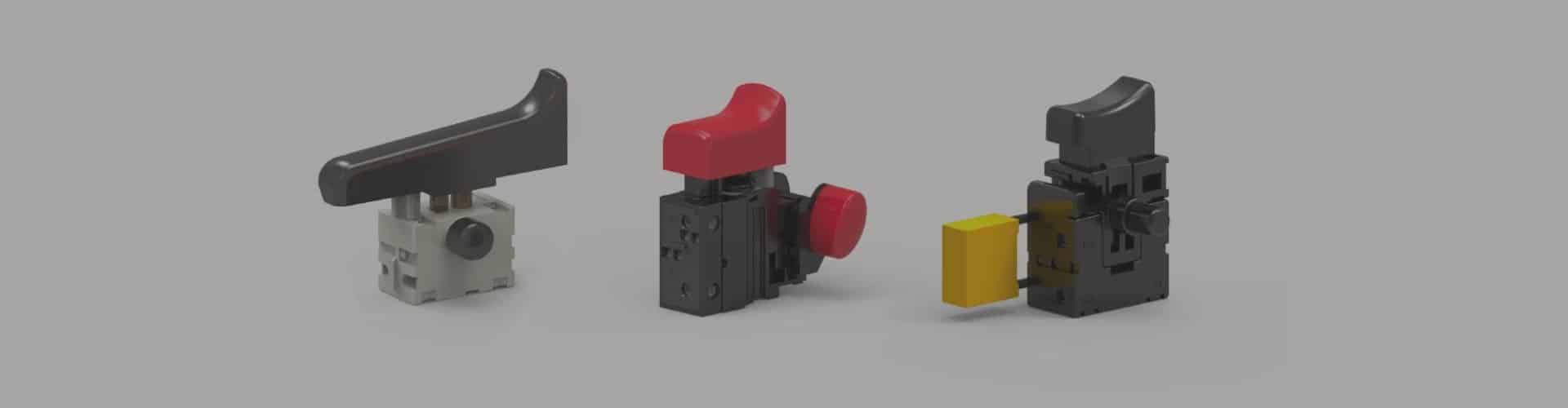

Types of Power Tool Switches: A Guide to Different Types in Angle Grinders

This section discusses the various types of power tool switches commonly found in angle grinders.

The on/off toggle switch is a simple and common type that allows for quick and easy control of the tool’s power.

Paddle switches require a bit more dexterity to operate as they are activated by pressing down on a button with one’s finger.

Deadman switches are designed to automatically turn off the grinder when pressure is released from the switch, making them a safer option for use in hazardous environments.

Lastly, electronic switches use sensors to detect changes in pressure or movement, providing precise and responsive control over the tool’s speed and power.

On/Off Toggle switches

Toggle switches are a common type of switch used in power tools such as angle grinders, which provide a simple and reliable method for turning the tool on or off. As the name suggests, toggle switches consist of a lever that is moved back and forth to turn the tool on or off. The lever is typically made of plastic or metal and may be covered with rubber or other materials to provide better grip and control.

On/off toggle switches can be found in different sizes and shapes depending on the angle grinder’s power tool switch manufacturer. They are commonly supplied by switch china manufacturers who produce them according to specifications provided by angle grinder manufacturers. These switches are also available from switch china factories that supply various types of switches for use in different industries. Switch china suppliers offer these switches at competitive prices, making them an affordable option for angle grinder manufacturers who want to keep production costs low while maintaining high-quality standards.

| Advantages | Disadvantages |

|---|---|

| Easy to use | Can accidentally be turned on/off |

| Simple design | May wear out over time |

| Reliable operation | Limited functionality |

| Inexpensive compared to other types of switches | No safety features present |

Overall, on/off toggle switches remain popular among users because of their simplicity, reliability, and affordability compared to other types of power tool switches. However, they do have some limitations such as limited functionality and lack of safety features that could make them less desirable in specific contexts where more advanced features are needed. It is essential to choose the right type of switch based on performance requirements and safety needs when using an angle grinder or any other power tool.

Paddle switches

Notably, paddle switches provide an alternative method for controlling power tools that is distinct from the traditional on/off toggle switch. Paddle switches are commonly found in angle grinders and other power tools where a constant pressure needs to be applied while operating the tool. This type of switch is designed to be operated with one hand and can easily be turned off by releasing the pressure on the paddle.

Paddle switches also come with added protection features such as a lock-on button that helps keep the tool running even if the operator takes their hand off the switch. This feature is useful when working with large workpieces or when a continuous cutting or grinding process is required.

Additionally, some angle grinders power tool switch china manufacturer may incorporate safety features like overload protection that automatically turns off the tool if it becomes too hot or encounters an obstruction while in use.

Overall, paddle switches offer more control and functionality than traditional toggle switches making them a popular choice among professionals and DIY enthusiasts alike.

- Lock-on button feature

- One-handed operation

- Overload protection

- Ideal for continuous cutting/grinding processes

Deadman switches

In our previous subtopic, we discussed paddle switches which are commonly used in angle grinders power tool switch. Now, we will tackle another type of switch called deadman switches.

Deadman switches are crucial safety features that prevent accidental activation of the grinder tool. The deadman switch is designed to shut off the grinder when the user releases pressure on the trigger.

Deadman switches are found in many angle grinders power tool switch manufacturers and China suppliers worldwide because they play a vital role in ensuring safe operation. Unlike lockon switches that can be accidentally activated, deadman switches require constant pressure from the operator to keep the grinder running.

This feature ensures that if an operator loses control or consciousness while using the machine, it will immediately stop working, reducing any potential accidents and injuries. With its safety features and dependable performance, it’s no wonder why many industries prefer using angle grinders with deadman switches for their grinding tasks.

Electronic switches

Electronic switches have become increasingly popular in recent years due to their precision and reliability in controlling the power tool’s operation.

In angle grinders, electronic switches provide more control over the speed of the tool. Unlike deadman switches, which only allow for on or off operation, electronic switches enable variable speeds that can be adjusted according to the task at hand. This feature is particularly useful when working with materials that require different speeds for cutting or grinding.

Moreover, electronic switches offer an additional level of safety by preventing accidental start-ups. They often come equipped with a lock-off button that needs to be pressed before initiating any action, ensuring that the operator has full control over the tool’s operation.

Additionally, some electronic switch models have overload protection features that automatically shut off the grinder if it overheats or encounters too much resistance during use. These safety features make electronic switches a preferred choice among professionals who prioritize both efficiency and safety while using power tools like angle grinders.

How Does a Power Tool Switch Work?

Power tool switches come in various types, each with its own mechanics and operation process.

On/Off toggle switches are a common switch type that operates through a simple mechanical lever or button system.

Paddle switches, on the other hand, require continuous pressure to maintain power and can be easily operated by the user’s thumb or finger.

Deadman switches are designed to disengage power when released, providing an added layer of safety for the user.

Finally, electronic switches operate through digital circuitry and provide advanced features such as variable speed control.

On/Off Toggle switches: Explain mechanics and operation process.

The mechanics of the On/Off Toggle switch on an angle grinder is a crucial aspect of its operation. This type of power tool switch involves a lever that moves back and forth to connect or disconnect the circuit, thus turning the grinder’s motor on or off. The lifespan of these switches can vary, but they typically last around 10,000 cycles before needing replacement.

To operate an On/Off Toggle switch safely and effectively, users must understand how it functions. When the lever is in the ‘on’position, it connects two metal contacts within the switch to complete a circuit. This sends electricity to the motor and causes it to spin.

Conversely, when the lever is moved to the ‘off’position, it breaks this connection and stops electricity from flowing through the motor. Understanding these mechanics is essential for ensuring that users can operate their angle grinder with maximum safety and efficiency.

Paddle switches: Explain mechanics and operation process.

Paddle switches on handheld devices, including angle grinders, are activated by a movable plastic or metal paddle that is connected to the switch mechanism.

Unlike toggle switches, which have an on/off position that is locked in place until manually switched again, paddle switches require constant pressure to remain in the ‘on’ position. Once released, the switch will automatically return to the ‘off’ position.

Understanding the mechanics and operation process of paddle switches is important for safe and effective use of power tools. Here are three key points to keep in mind:

- Paddle switches require continuous pressure to stay on, which can be tiring for extended use.

- The positioning of the switch can affect ergonomics and ease of use.

- Some models may offer additional safety features such as lock-on buttons or two-stage triggers.

Deadman switches: Explain mechanics and operation process.

With a quick release and safety mechanism, the deadman switch acts as a lifeline for workers in hazardous industries. This power tool switch is designed to turn off the angle grinder or other power tools when it is not being held by the operator. The deadman switch is also known as a kill switch, which instantly turns off the machine when released.

The mechanics behind this type of power tool switch are relatively simple. The deadman switch consists of two parts: a spring-loaded lever and an electrical contact. When pressure is applied to the lever, it compresses the spring and closes the electrical contact, allowing current to flow through the machine. However, if pressure on the lever is released, then the spring will return to its original position and open up the electrical contact, stopping current from flowing through. The operation process for using this type of power tool switch involves holding down on it with one hand while operating with your other hand, ensuring accuracy during operation.

| Advantages | Disadvantages |

|---|---|

| Increases safety in hazardous work environments | Can be accidentally triggered |

| Provides control over equipment | Requires constant attention |

| Prevents accidental start-up of machinery | May cause user fatigue |

| Allows for easy shut-off in case of emergencies | Switch may need periodic maintenance |

Deadman switches provide an essential safety feature for workers using angle grinders or other types of power tools in hazardous environments. Their simple mechanics allow them to function efficiently while providing users with precise control over their equipment’s operations. Although they do require constant attention from operators to ensure accuracy during use and can sometimes cause user fatigue due to this requirement – these disadvantages are outweighed by their benefits regarding increased safety measures taken throughout various industries that utilize large machinery daily!

Electronic switches: Explain mechanics and operation process.

Electronic switches, commonly used in various industrial applications, operate through electronic components rather than mechanical ones and provide precise control over power distribution. These switches are also present in angle grinders as the power tool switch.

Electronic switches can be found in different types such as MOSFETs, IGBTs and BJTs. MOSFET-based electronic switches are the most popular due to their high-speed switching capability and less power loss.

The angle grinder’s electronic switch is designed by the manufacturer to ensure safety and prevent accidents while using the tool. It provides better control over the speed of rotation of the grinding wheel.

The use of an electronic switch allows for a longer lifespan for batteries on cordless angle grinders compared to those that use traditional mechanical switches. An electronic switch does not wear out easily which means it will last longer than a mechanical switch, eliminating the need for frequent replacements.

Additionally, unlike deadman switches or other mechanical switches which typically have fixed time intervals between on-off cycles, an electronic switch can maintain its state until it receives another signal from the user to change its state. This feature makes it more convenient for users who want to start and stop their work intermittently at any time without having to worry about resetting their tool every time they want to continue grinding or cutting with their angle grinder.

Choosing the Right Angle Grinder Switch: Key Factors to Consider

When selecting an angle grinder, it is important to consider the design of its power tool switch. Three key factors to keep in mind are ergonomics and ease of use, safety features, and durability.

The switch should be easy to operate without causing strain or discomfort, incorporate safety mechanisms such as a lock-on feature or emergency stop button, and have a robust construction that can withstand frequent use without malfunctioning.

These considerations will help ensure a safe and efficient working experience with the angle grinder.

Ergonomics and ease of use

Efficient and comfortable usage is a crucial aspect to consider when evaluating the ergonomics of an angle grinder’s power tool switch. The size and design of the switch should be such that it can be easily operated with one hand, allowing for greater control and precision when working on different surfaces.

Additionally, the placement of the switch is also important as it should be within easy reach, preventing hand fatigue and strain.

The presence of an ergonomic handle can also greatly enhance ease of use. An angle grinder with a well-designed handle enables users to maintain a comfortable grip during extended periods of use, reducing the risk of injury or discomfort caused by repetitive motion.

Furthermore, this feature allows users to apply more pressure when using larger discs or working on tougher surfaces without experiencing excessive fatigue. Overall, choosing an angle grinder with an ergonomic power tool switch design ensures that users enjoy efficient and safe performance during their work activities.

Safety features

In order to ensure the safety of users, angle grinders are equipped with various features that minimize the risk of injuries. These safety features are typically implemented by the manufacturer and include a protective guard that shields against flying debris, as well as a lock-off switch that prevents accidental start-ups.

The guard is designed to cover the abrasive or grinding discs and protect users from any fragments that may be generated during use. The lock-off switch, on the other hand, is meant to prevent the grinder from being turned on accidentally while it’s not in use.

Apart from these two primary safety mechanisms, many angle grinders also come with blade guards that help reduce the risk of injury even further. These guards can vary in design and are often adjustable to accommodate different types of applications.

It’s important for users to carefully read through their grinder’s manual before using it so they can understand how best to adjust and utilize these features. Ultimately, by being aware of these safety measures and following proper usage procedures, individuals can minimize their risk of experiencing serious injuries when operating an angle grinder power tool switch.

Durability

The durability of an angle grinder is a crucial aspect to consider when choosing a power tool switch. The longevity of the tool is highly dependent on the materials used in its construction, as well as how often and intensively it is used. In addition, maintenance practices employed by users can also impact the lifespan of the tool.

Angle grinders are typically constructed with durable materials such as steel and aluminum to withstand tough working conditions. However, due to their abrasive nature, they require additional features such as dust seals to prevent debris from entering the motor housing and causing damage over time. Regular cleaning and lubrication can also help prolong the life of an angle grinder by preventing rust or corrosion from forming on its components.

Employing safety precautions such as using appropriate protective gear during operation can also minimize wear and tear on an angle grinder’s parts and increase its overall durability.

Common Issues and Troubleshooting Tips

The power tool switch is a crucial component of an angle grinder that can sometimes cause issues. In this section, we will address some common problems related to power tool switches in angle grinders.

Additionally, we will provide troubleshooting tips for basic issues users may encounter when using their angle grinder’s power tool switch. By understanding these common issues and how to solve them, users can ensure that they are able to operate their angle grinder safely and effectively.

Common problems related to power tool switches in angle grinders can be resolved through a systematic approach to troubleshooting. The first step is to identify the problem by observing the behavior of the switch when it is turned on or off.

Some common issues include switches that fail to turn on, switches that stay on even after being released, and switches that fail to turn off completely.

Once the issue has been identified, the next step is to determine what is causing it. This may involve checking for loose connections, damaged wiring, or worn-out components such as switches or capacitors.

In some cases, simply cleaning and lubricating the switch mechanism can resolve the issue. However, if more significant repairs are needed, it may be necessary to replace parts or seek professional assistance in order to ensure that the angle grinder remains safe and functional.

By understanding these common problems related to power tool switches in angle grinders, users can take steps to address them effectively and keep their tools working smoothly over time.

- Loose connections: Check all connections between the switch and other components of the grinder for signs of looseness or damage.

- Wiring issues: Inspect wires for fraying or other damage that may interfere with proper functioning of the switch.

- Component wear: Look for signs of wear on individual components such as capacitors or resistors that could cause issues with switching performance.

Provide troubleshooting tips for basic issues users may encounter.

After addressing common problems related to power tool switches in angle grinders, it is important to provide troubleshooting tips for basic issues users may encounter.

One of the most common issues with angle grinder switches is that they may not turn on or off properly. This can be caused by a variety of factors such as a faulty switch, loose wiring, or a damaged cord.

To troubleshoot this issue, users should first check the power source and ensure that it is functioning properly. If the power source is working correctly, then users should inspect the switch and wiring for any visible damage or loose connections.

Another issue that users may encounter with their angle grinder’s power tool switch is difficulty adjusting speed settings. This can be due to a malfunctioning speed control mechanism or improper use of the tool.

To troubleshoot this issue, users should refer to their user manual for proper usage instructions and make sure they are using the correct attachments for their desired task. Additionally, if there are switch adjustments available on the tool itself, users should experiment with these settings to find the optimal speed for their specific task.

It is important to always follow safety precautions when troubleshooting any issues with an angle grinder’s power tool switch and never attempt repairs without proper training or experience in electrical work.

Safety Precautions for Working with Angle Grinder Power Tool Switches

When operating an angle grinder, it is crucial to put safety measures in place to prevent accidents. Essential precautions include wearing personal protective equipment such as gloves, eye protection, and ear defenders.

Proper handling of the tool is also critical to avoid injury, including ensuring a secure grip on the handle and carefully positioning the workpiece during use.

By following these guidelines and taking necessary precautions, users can minimize the risk of accidents while working with angle grinders.

Essential Safety Measures for Operating Angle Grinders

Important safety measures must be strictly followed by users when operating angle grinders to prevent serious injuries or accidents. The power tool switch of an angle grinder is an essential feature that requires proper handling to reduce the risk of accidents. Before using an angle grinder, it is crucial to read and follow the manufacturer’s instructions carefully. Users should also ensure that they have received adequate training on how to operate the tool safely.

The table below highlights some essential safety measures that users should follow when operating angle grinders:

| Safety Measures | Description |

|---|---|

| Wear Personal Protective Equipment (PPE) | PPE such as eye protection, earplugs, gloves, and a face shield can help protect against flying debris and noise-induced hearing loss. |

| Inspect the Angle Grinder Before Use | Check for any visible signs of damage or wear on the tool before using it. Ensure that all guards are in place and securely fastened. |

| Securely Hold the Angle Grinder | Firmly grip the tool with both hands while in use to maintain control at all times. Avoid overreaching or awkward positions while operating the angle grinder. |

| Use Appropriate Discs for Specific Tasks | Using incorrect discs can cause serious injury or damage to both the user and equipment. |

| Turn Off Power Tool Switch When Not in Use | Always turn off and unplug the angle grinder after use, especially when changing accessories. |

By following these safety measures when operating an angle grinder, users can minimize their risk of accidents or injuries associated with this powerful power tool switch device.

Include tips on proper handling and precautions to avoid accidents

In order to ensure safe use of angle grinders, it is important to follow essential safety measures when operating the power tool switch. These include wearing proper protective gear such as gloves, goggles, and earplugs, ensuring that the work area is clear of any objects or debris that may interfere with the grinding process, and never using a damaged or malfunctioning dewalt angle grinder.

Proper handling and precautions are also necessary in preventing accidents while using an abrasive grinding disc. One should always hold the angle grinder with both hands firmly and securely during operation, keeping fingers away from the blade at all times.

It is also recommended to avoid overexertion when using this tool and taking regular breaks to prevent fatigue or strain on muscles. By following these guidelines for safe use of angle grinders, we can significantly reduce risks of injury or harm in our daily work tasks involving power tools.

FQQ: Frequently Asked Questions

Can an angle grinder’s power tool switch be repaired if it malfunctions?

If an angle grinder’s power tool switch malfunctions, it may be possible to repair it depending on the extent of the damage. However, this would require a thorough understanding of the specific model and type of switch used in the grinder.

In some cases, it may be more cost-effective to replace the switch or even the entire tool rather than attempting to repair a faulty switch.

It is important to note that attempting any repairs on a power tool without proper knowledge and training can be dangerous and should only be carried out by qualified professionals.

Additionally, regular maintenance and inspection of power tools can help prevent malfunctions and ensure safe operation.

What is the average lifespan of an angle grinder’s power tool switch?

The average lifespan of an angle grinder’s power tool switch can vary depending on the frequency and intensity of its usage. However, it is generally expected to last for several years.

With proper maintenance and care, the switch can continue to function properly without any issues. Regular cleaning and lubrication can extend the lifespan of the switch, while rough handling or exposure to external factors such as dust or moisture may cause premature failure.

It is recommended to replace a malfunctioning switch rather than attempting repairs, as this ensures safe and optimal performance of the tool.

Are there any safety certifications that a power tool switch should have?

There are various safety certifications that a power tool switch can have, depending on the country where it is manufactured or sold. One of the most recognized international standards for power tools is the International Electrotechnical Commission (IEC) 60745-1:2018.

This standard specifies general safety requirements for hand-held electric motor-operated tools, including requirements for switches and control devices. In addition, other certifications and regulations may be applicable to specific types of switches, such as those used in explosion-proof environments or medical equipment.

It is important to note that compliance with these standards does not guarantee complete safety, but rather serves as a baseline requirement for manufacturers to meet in order to minimize risks associated with using power tools.

Can a power tool switch be customized for a specific application?

Yes, a power tool switch can be customized for a specific application. By modifying the design and functionality of the switch, it is possible to tailor it to meet the specific needs and requirements of a particular task or industry.

Customized switches can help improve safety and efficiency by providing precise control over the tool’s operation, reducing the risk of accidents or damage to equipment. However, proper testing and certification are essential to ensure that customized switches meet all necessary safety standards and regulations before they are put into use.

Therefore, it is important for manufacturers and users alike to consult with experts in power tool design and engineering to determine how best to customize switches for their specific applications while ensuring compliance with all relevant safety guidelines.

Are there any special maintenance requirements for an angle grinder’s power tool switch?

In general, power tool switches require regular maintenance and cleaning to ensure optimal performance. However, there are no specific special maintenance requirements for an angle grinder’s power tool switch beyond these standard procedures.

It is important to regularly inspect the switch for any signs of wear or damage and replace it if necessary. Additionally, keeping the switch clean and free of debris can help prevent malfunctions or accidents.

Overall, following proper maintenance practices and being cautious while using the angle grinder can help ensure safe and effective operation over time.

Conclusion

In conclusion, understanding the power tool switch in angle grinders is crucial for both safety and efficiency reasons. It is essential to comprehend the anatomy and types of switches available to make an informed decision when selecting the right angle grinder for a job.

The intricate workings of a power tool switch can be compared to the complex inner workings of a clock; each component must work together seamlessly for optimal function.

Moreover, just as one must handle delicate clockwork with care, handling an angle grinder’s power tool switch requires caution and attention to detail. By following proper safety protocols, including wearing protective gear and ensuring a stable working surface, one can mitigate potential hazards associated with using these powerful tools.

Ultimately, understanding and respecting the importance of an angle grinder’s power tool switch is key to achieving successful results while maintaining personal safety.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd