Angle grinders are powerful tools used in various industries for cutting, grinding, and polishing materials. They have a rotating disc that rotates at high speeds to perform the task at hand. One of the most important components of an angle grinder is its switch.

The switch controls the on and off function of the tool, making it an essential safety feature. Understanding the types and functions of angle grinder switches is crucial to safely operate this tool. There are different types of switches available with varying features, which can impact how you use your angle grinder.

This article aims to provide an in-depth analysis of angle grinder switches, including their types, functions, and safety tips to ensure proper usage.

Introduction Angle Grinder Switch

Angle grinders are versatile power tools that find applications in various industries, including metalworking, construction, and woodworking.

The angle grinder switch is a critical component of the tool that allows for its operation.

Understanding the types, functions, and safety tips associated with angle grinder switches is essential to ensure safe and efficient use of the tool.

Brief explanation of angle grinders and their use in various industries

This section explores the diverse applications of a handheld power tool employed in a range of industries. The angle grinder is a versatile and powerful tool that has found its way into many different fields, including construction,metal fabrication, woodworking, and automotive repair. It is commonly used for cutting, grinding, sanding, polishing, and shaping materials such as metal, stone, concrete, brick, and tile.

Here are five common uses of an angle grinder in various industries:

- Cutting through rusted bolts or old pipes during plumbing repairs.

- Shaping metal parts in automotive shops to fit specific designs.

- Grinding down welds on construction sites to create smooth surfaces.

- Polishing granite countertops or concrete floors in home renovations.

- Smoothing rough edges on wooden pieces for carpentry projects.

Despite its usefulness, the angle grinder can be dangerous if not handled with care. That’s why it’s important to understand how the switch works and follow proper safety guidelines when using this tool.

Importance of having a good understanding of the angle grinder switch

Having a comprehensive knowledge of the operation and functionality of the switch on an angle grinder is critical to ensuring safe and effective use in various industries. The angle grinder switch is responsible for controlling the power supply to the motor, which determines the speed at which the blade rotates. It is crucial to understand the different types of switches available for angle grinders and their functions, as well as safety tips when using them.

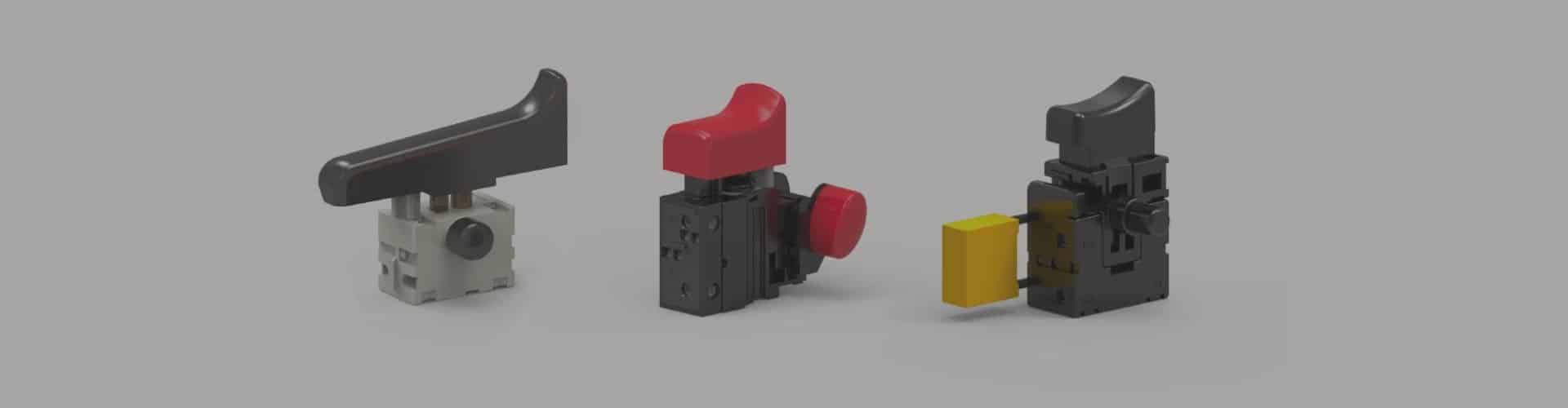

There are two main types of switches found on angle grinders: paddle switches and trigger switches. Paddle switches are located on top or at the rear of an angle grinder, while trigger switches are located at the front or near the handle. Paddle switches require both hands to operate, making it more difficult for accidental activation, while trigger switches can be operated with one hand but may be prone to accidental activation if not used carefully. When using an angle grinder switch, it is essential to follow safety tips such as wearing protective gear like gloves and goggles, keeping your work area clean and tidy, avoiding forcing blades through materials that they cannot cut easily, and never leaving your tool unattended while it’s still running. By following these guidelines and having a good understanding of how your angle grinder switch works, you can ensure safe use in various industries without compromising performance or quality output.

| Types | Functions | Safety Tips |

|---|---|---|

| Paddle Switches | Located on top or at rear; requires both hands to operate | Wear protective gear; keep work area clean |

| Trigger Switches | Located near front or handle; can be operated with one hand | Avoid forcing blades through tough materials; never leave tool unattended while still running |

Types of Angle Grinder Switches

This section will discuss the types of switches commonly found on angle grinders.

The three main types are toggle switch, paddle switch, and dead man’s switch.

Each type has its own advantages and disadvantages in terms of ease of use and safety features.

Toggle Switch

The toggle switch is a type of switch commonly found on angle grinders. It works by allowing the user to easily turn the grinder on and off with a simple flick of a lever.

While this type of switch is convenient, it can also be dangerous if not used properly. Understanding how it works and its advantages/disadvantages can help ensure safe operation of an angle grinder.

How it works and its advantages/disadvantages

Exploring the operational mechanics and comparative merits of an angle grinder’s on/off switch can inform one’s decision-making process when selecting the appropriate tool for a given task.

The toggle switch, also known as the button switch or slide switch, is commonly found in angle grinders and works by sliding or toggling to turn the tool on or off.

Its advantages include ease of use and familiarity for users who are accustomed to traditional switches, while its disadvantages may include accidental activation due to its simple design and lack of safety features.

To prevent such accidents from occurring, it is important to follow safety tips such as keeping fingers away from the switch when not in use, using both hands when operating the tool, and ensuring that the power source is disconnected before making any adjustments or repairs.

Overall, understanding how a toggle switch functions can increase awareness of potential hazards associated with angle grinder usage and improve overall safety practices.

Paddle Switch

The paddle switch is another type of switch used in power tools. Unlike the toggle switch, the paddle switch is a trigger that must be held down to keep the tool running.

One advantage of the paddle switch is that it allows for greater control over the tool’s operation, as releasing the trigger immediately stops its movement. However, some users may find this type of switch less comfortable to use for extended periods of time compared to a toggle switch.

How it works and its advantages/disadvantages

Examining the mechanics and merits of the angle grinder switch’s operation can provide valuable insights into its efficacy and potential applications in various settings.

The paddle switch, as a type of angle grinder switch, functions by using a lever that needs to be pressed down for the tool to operate, which is then released to turn it off. This mechanism ensures that accidental triggering of the grinder is minimized and provides greater control over the tool’s speed and operation.

One advantage of this type of switch is that it allows for quick shut-off in case of an emergency or when changing grinding wheels. However, one disadvantage is that prolonged use may cause fatigue on the operator’s hand due to continuous pressure applied on the lever while working with the tool.

Nonetheless, understanding how this switch works and its advantages/disadvantages can help ensure safety measures are taken when operating an angle grinder with a paddle switch.

Dead Man’s Switch

The dead man’s switch is a safety mechanism found in many power tools that automatically shuts off the tool if the operator loses control or consciousness.

This type of switch works by requiring constant pressure from the operator to keep the tool running, and if pressure is released, it will quickly shut off.

While this can be a useful safety feature for some applications, it also has its disadvantages such as limiting productivity and causing fatigue for operators who must maintain constant pressure.

How it works and its advantages/disadvantages

Exploring the mechanics and operational benefits of the angle grinder switch sheds light on its inner workings, revealing how it can be employed to effectively complete a wide range of tasks.

The dead man’s switch is one of the most popular types of switches utilized in angle grinders as it automatically shuts off the tool when released or dropped, promoting safety and preventing accidents. This type is advantageous because it ensures that the tool will not continue operation without proper handling from the operator.

However, there are also disadvantages to this type of switch as it may cause fatigue or strain due to continuously pressing down on the button while working. Another type of switch is the lock-on switch which allows for continuous operation without holding down a button but poses a higher risk for accidents if not used properly.

It is essential to understand these types and their functions along with implementing safety tips such as wearing protective gear, avoiding loose clothing, inspecting equipment before use and properly storing tools after usage in order to prevent injuries.

Functions of an Angle Grinder Switch

The angle grinder switch serves various functions, including the On/Off function, Speed Control Function, and Safety Lock-out Function.

The On/Off function allows for easy activation or deactivation of the tool.

The Speed Control Function is used to adjust the speed of the grinder to suit specific applications.

The Safety Lock-out Function helps prevent accidental start-up of the tool.

On/Off Function

The switch is a crucial component of an angle grinder that controls the power supply to the motor. It determines whether the grinder is on or off and regulates the speed of rotation.

Understanding the different types of switches, their functions, and safety tips is essential for safe and efficient use of angle grinders in various applications.

Detailed explanation of how the switch controls the power supply to the grinder’s motor

The intricate mechanism of the angle grinder switch regulates the flow of electricity to the motor and ultimately determines the speed and power output of the tool, emphasizing the importance of mastering its operation for safe and efficient use.

The angle grinder switch can come in different types, such as a paddle switch or a slide switch, each with its own unique functionality. When activated, these switches either complete or interrupt an electrical circuit that controls the current flowing through the motor. Depending on how it is manipulated, this results in varying levels of power output that can be adjusted to suit different tasks.

In order to ensure safe operation, it is important to understand how each type of switch operates and practice proper handling techniques when operating an angle grinder. This includes using both hands to grip the tool securely while maintaining a firm grasp on the handle to keep it steady during use.

Speed Control Function

The speed control function is an essential feature of angle grinders that enables users to regulate the tool’s speed based on their specific needs. This function helps to minimize the risk of accidents and damage to materials by allowing for precision work.

Different models of angle grinders have varying types of switches, which play a crucial role in regulating the speed.

Detail on how the switch helps regulate speed on different models.

Regulating the speed on an angle grinder is made possible through a switch that controls the amount of electricity flowing to the motor, allowing for versatile use across different models.

The angle grinder switch acts as a speed controller by regulating the flow of current from the power source to the motor. This helps users adjust their tool’s speed based on their needs, which can range from delicate tasks such as sanding or polishing to heavy-duty grinding applications.

Different types of angle grinders come with various switches, including paddle switches, slide switches, and trigger switches. It is crucial to know how each switch works and how it affects your control over the tool’s speed before using an angle grinder.

Additionally, proper safety tips should always be followed when operating an angle grinder regardless of its switch type to prevent accidents and injuries.

Safety Lock-out Function

The safety lock-out function is an essential feature in an angle grinder that ensures the operator’s safety when changing blades or adjusting the tool.

This function prevents accidental start-up of the tool, which may cause severe injuries to the operator.

It is crucial to understand how this feature works and use it appropriately to prevent any accidents while using an angle grinder.

The importance of this function when changing blades or adjusting the tool.

When altering the blade or adjusting the angle grinder, this crucial feature enables users to have precise control over the tool’s speed and power.

The safety lock-out function is an integral part of the angle grinder switch that ensures safe operation during blade changes.

This function prevents accidental activation of the tool by requiring users to depress a button or lever before engaging the trigger.

It also allows for adjustments in speed and power while maintaining maximum safety.

When changing blades, it is important to follow all safety guidelines provided by the , including disconnecting power sources and ensuring that blades are securely fastened before use.

By utilizing this safety lock-out function, users can prevent injury and ensure proper use of their angle grinder while changing blades or making adjustments to their tool.

Factors to Consider When Choosing an Angle Grinder with a Switch

When choosing an angle grinder with a switch, there are several factors to consider such as the type of application, ergonomics and durability.

The type of application refers to the purpose for which the angle grinder will be used, whether it is for heavy-duty tasks or light tasks.

Ergonomics deals with how comfortable and efficient the angle grinder is to use while durability refers to its ability to withstand wear and tear over time.

Considering these factors would enable one to make an informed decision when selecting an angle grinder with a switch that best suits their needs.

Type of Application

When selecting an angle grinder, one important consideration is whether you need a tool with continuous or intermittent duty.

Continuous duty tools are designed for extended use and can run for long periods of time without overheating.

Intermittent duty tools, on the other hand, have cooling mechanisms that allow them to be used for shorter durations before requiring a break.

Understanding the differences between these types of applications can help ensure that you choose the right tool for your needs and promote safe usage practices.

Whether you need a continuous or intermittent duty tool

The duty cycle of an angle grinder is a crucial consideration when selecting the appropriate tool for a particular task, as it determines whether the tool can sustain prolonged use without overheating and potentially causing damage or injury.

Angle grinders come in two duty cycle types: continuous operation and intermittent operation. Continuous operation tools are designed to run for extended periods without overheating, making them ideal for heavy-duty tasks like grinding, sanding, and cutting thicker materials. Intermittent operation tools are better suited for lighter tasks that require less power, such as polishing or sharpening.

When using an angle grinder switch, it’s essential to follow safety tips to avoid accidents or injuries. These include wearing protective gear like gloves and goggles, keeping the work area clean and clear of debris, maintaining proper grip on the tool at all times, and avoiding distractions while operating the tool.

By understanding the different types of duty cycles and following safety guidelines when using an angle grinder switch, you can ensure that you select the right tool for your task while minimizing risks associated with its usage.

Ergonomics

In the context of an angle grinder, ergonomics refers to the study of designing machines that are comfortable, easy to grip and use.

Comfort is a crucial factor in reducing hand fatigue while using an angle grinder for extended periods.

The handle design should provide a secure grip without slipping, which enhances safety during operation.

Comfort, grip, and ease of use when handling the machine.

Achieving a comfortable grip and ease of use when handling an angle grinder is crucial for ensuring precision and accuracy during operation. Comfort is one aspect that should be considered, as the user will need to hold the machine for an extended period. The machine’s grip should fit comfortably in the hand without causing any discomfort or strain.

The lock-on feature can also contribute to comfort since it allows continuous operation without having to press down on the switch button constantly. Additionally, motor-protection features such as soft-start and overload protection can help make the tool easier to handle by reducing vibrations and preventing overheating.

When choosing repair parts for an angle grinder, it is essential to consider how they will affect comfort and ease of use while operating the tool.

Durability

The durability of the switch mechanism is an important aspect to consider when selecting an angle grinder.

The longevity and reliability of this component can impact the overall lifespan and effectiveness of the tool.

Manufacturers may use different materials and designs to increase durability, so researching these options can help ensure a worthwhile investment.

The quality and lifespan of the switch mechanism.

The durability and longevity of the switch mechanism is a crucial aspect to consider when using an angle grinder, as it directly impacts the tool’s overall performance and reliability. The quality of the switch can vary depending on the type of angle grinder being used, with some models having better switches than others.

It is important to choose an angle grinder with a high-quality switch in order to ensure that it will last for a long time and perform reliably throughout its lifespan. Additionally, proper maintenance and usage can also help prolong the lifespan of the switch mechanism.

When using an angle grinder, always follow safety tips such as wearing appropriate protective gear, checking the tool before use, and avoiding overloading or overheating the motor. By taking these precautions and choosing a high-quality angle grinder with a durable switch mechanism, users can ensure safe and effective use of this powerful tool.

Angle Grinder Safety Tips to Follow

When it comes to using an angle grinder, safety should always be a top priority.

Understanding personal protective equipment (PPE), proper handling techniques, and careful inspection before use are essential in ensuring the safe use of this power tool.

By following these guidelines, users can greatly reduce the risk of accidents and injuries while operating an angle grinder.

Understanding Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is essential for individuals who work with power tools like angle grinders. When using an angle grinder, appropriate clothes such as long-sleeved shirts and pants should be worn to protect the skin from sparks and debris.

Additionally, face shields or goggles and gloves should also be used to minimize the risk of injury to the eyes and hands.

Appropriate clothes, face shields/goggles, gloves for safety purposes.

Appropriate safety gear, including protective clothing, face shields/goggles, and gloves, is essential when operating an angle grinder to prevent injuries or accidents.

Protective clothing should cover the entire body and be made of flame-resistant material. It should also fit snugly to avoid getting caught in the tool’s moving parts.

A face shield or goggles are necessary to protect the eyes from flying debris generated by the angle grinder’s abrasive disc. The face shield should provide full coverage of the face and neck with a clear lens that does not distort vision.

Gloves are also important for protecting hands from cuts and burns caused by contact with hot metal shavings or sparks produced during grinding operations. However, it is crucial to choose gloves that do not get caught in the rotating disc or restrict hand movement while using the tool.

When selecting personal protective equipment (PPE), it is recommended to consult with a professional regarding what specific type of gear will ensure maximum protection against potential hazards posed by the angle grinder switch.

Proper Handling Techniques

This section will discuss proper handling techniques for angle grinders.

Safe handling practices include using both hands while operating the grinder and avoiding excessive force that could cause injury or damage to the tool.

These techniques are important for maintaining a safe workplace and reducing the risk of accidents.

Safe ways to handle an angle grinder that includes using both hands while operating and avoiding excessive force.

Proper handling of an angle grinder involves the use of both hands during operation to maintain control and avoiding applying excessive force, which can lead to accidents and injuries. The angle grinder switch is typically located on the side or top of the tool and requires a firm grip to operate. It is important not to use one hand only or hold the tool with one hand while operating as this can cause loss of control and severe injury.

Two-handed operation provides better stability, control, and balance when using an angle grinder. Additionally, avoiding excessive force prevents the risk of kickback which occurs when the blade gets stuck in a material causing it to jump back towards you suddenly. This can be avoided by keeping a steady pace while cutting and using proper pressure on the wheel.

It is also essential that users wear protective gear such as gloves, safety glasses, earplugs, and a face shield when using an angle grinder for added protection against flying debris or sparks generated during use.

Overall, following these safety tips will help ensure safe usage of an angle grinder for various applications without risking injury or damage to property.

Careful Inspection Before Use

Before using an angle grinder, it is crucial to perform a careful inspection of all its components and cords for any signs of damage or flaws.

This step ensures that the tool is safe to use and prevents potential accidents from occurring during operation.

Therefore, it is recommended to check the tool’s condition thoroughly before plugging it in and starting any work.

Checking all components, cords for damage or flaws before plugging them in.

Prior to usage, it is important to meticulously inspect all components and cords for any signs of damage or flaws to ensure safe operation of the angle grinder switch.

Checking all parts of the angle grinder is essential because any damage or flaws can lead to serious accidents or injuries during use.

Components that should be checked thoroughly include the grinding wheel, guard, handle, and power cord.

It is important to check if there are any cracks on the grinding wheel that could cause it to shatter when in use.

The guard should also be checked if it is securely attached as it protects the user from sparks and debris while using the tool.

Additionally, checking for any frayed or cut wires on the power cord will prevent electrical hazards from occurring.

In conclusion, taking time to carefully inspect all components and cords before plugging in an angle grinder switch can help ensure a safer work environment and prevent accidents due to faulty equipment.

Conclusion

In conclusion, understanding the angle grinder switch is crucial for individuals who work with power tools.

There are various types of switches available in the market, and it is essential to choose one that suits the task at hand.

It is equally important to follow safety tips when operating an angle grinder. This includes wearing protective gear such as goggles, gloves, and earplugs.

While using an angle grinder, individuals should keep a firm grip on the tool and avoid overexerting themselves.

Additionally, they must ensure that they have a clear workspace and remove any potential hazards from their surroundings.

Lastly, never leave an angle grinder unattended while it’s still running or plugged in.

By following these safety tips and having a good understanding of the switch mechanism, individuals can prevent accidents from happening in the workplace and ensure their personal safety while working with power tools like angle grinders.

Frequently Asked Questions

What is the best way to clean an angle grinder switch?

To clean an angle grinder switch, it is important to first ensure that the tool is unplugged and turned off.

Using a soft-bristled brush or compressed air, gently remove any debris that may have accumulated around the switch.

A small amount of rubbing alcohol can be applied to a cloth or cotton swab to clean any grime or dirt on the switch itself.

It is important not to use harsh chemicals or solvents as these can damage the electrical components of the tool.

Regular cleaning of the switch can help prevent malfunctions and prolong the lifespan of the angle grinder.

Can angle grinder switches be repaired if they stop working?

Angle grinder switches can sometimes stop working, leaving users wondering if they can be repaired. The answer to this question is not straightforward and depends on the nature of the problem with the switch.

In some cases, such as a broken or loose connection, it may be possible to repair the switch. However, in other cases where there is an internal fault or damage to the switch mechanism itself, replacement may be necessary.

It is important to note that attempting to repair an angle grinder switch without proper knowledge and training can be dangerous and should only be done by a qualified professional.

Regular maintenance and care of your angle grinder can help prevent issues with the switch and ensure safe operation.

How do I know if my angle grinder switch is compatible with my power supply?

Determining if an angle grinder switch is compatible with a power supply involves considering several factors. Firstly, it is essential to examine the voltage and amperage requirements of both the switch and the power supply, ensuring that they match.

Additionally, one should ensure that the switch type corresponds with the power supply’s intended use. For instance, switches designed for industrial settings may not work efficiently in small DIY projects due to differences in their components and design.

It is also crucial to consider safety features such as overload protection that prevent damage to both the motor and user. Ultimately, proper matching of an angle grinder switch with a power supply ensures optimal performance and reduces risks associated with electrical accidents.

Can I use my angle grinder switch with different types of blades or discs?

The compatibility of an angle grinder switch with different types of blades or discs depends on the size and type of the switch. It is important to check the ‘s specifications for the tool as well as the blade or disc being used to ensure proper fit and operation. Using an improper switch can result in damage to both the tool and operator.

Additionally, it is crucial to follow safety guidelines when operating an angle grinder, including wearing appropriate personal protective equipment and ensuring that all guards are properly installed. Failure to do so can result in serious injury or death.

Are there any special considerations for using an angle grinder switch in wet or damp conditions?

When using an angle grinder switch in wet or damp conditions, there are several special considerations that must be taken into account.

First and foremost, it is essential to ensure that the tool is properly grounded and all electrical connections are secure before use.

Additionally, it is important to use only blades or discs that are specifically designed for use in wet conditions, as using standard blades can increase the risk of injury or damage to the tool itself.

Finally, it is crucial to wear appropriate safety gear such as rubber gloves and boots to protect against electric shock and slipping on wet surfaces.

By following these guidelines, individuals can safely and effectively use an angle grinder switch in wet or damp conditions without risking injury or damage.

Conclusion

In conclusion, understanding the angle grinder switch is crucial for anyone planning to use this tool. Different types of switches have their unique functions and advantages that users should consider before making a purchase.

The paddle switch and dead man’s switch are two common types available in the market, with each having its safety features. When selecting an angle grinder with a switch, several factors need consideration, such as the intended use of the tool and user experience level.

Furthermore, it is essential to adhere to safety tips while using an angle grinder to prevent accidents and injuries. Proper handling of these tools can lead to efficient results without compromising on user safety.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd