Contents hide

Toggle switches are fundamental electrical components that have revolutionized how we control electronic circuits and devices. These versatile mechanical switches provide a simple yet effective means of controlling electrical current flow through a manual lever or handle mechanism. In today’s interconnected world, toggle switches continue to play a crucial role across numerous industries, from telecommunications and medical equipment to industrial control systems and consumer electronics.

The global toggle switch market has seen steady growth, driven by increasing automation in manufacturing, rising demand for electronic devices, and expanding applications in emerging technologies. As we move through 2025, toggle switches remain irreplaceable components in countless applications where reliable manual control is essential.

This comprehensive guide explores everything B2B professionals need to know about toggle switches – from basic operating principles and types to selection criteria and industry applications. Whether you’re an engineer designing a new product, a procurement specialist sourcing components, or a technical manager evaluating options, this guide will provide valuable insights to inform your decisions.

How Toggle Switches Work

At their core, toggle switches are simple mechanical devices that control electrical circuits by manually moving a lever between positions. Despite this simplicity, understanding their working principles is essential for proper selection and application.

Basic Operating Principles

Toggle switches function by moving a metal contact from one position to another, either completing or breaking an electrical circuit. The fundamental toggle switch design includes an armature (a component carrying electrical current) attached to the toggle lever. When pulled, this armature places an electrical contact into a circuit or removes it, thereby activating or deactivating the circuit.

The switch typically remains in position until manually moved again, though momentary switches include a spring mechanism that returns the actuator to its starting position when released. This mechanical action provides tactile feedback to users, confirming the switch’s state change through both physical resistance and an audible click.

Mechanical Components

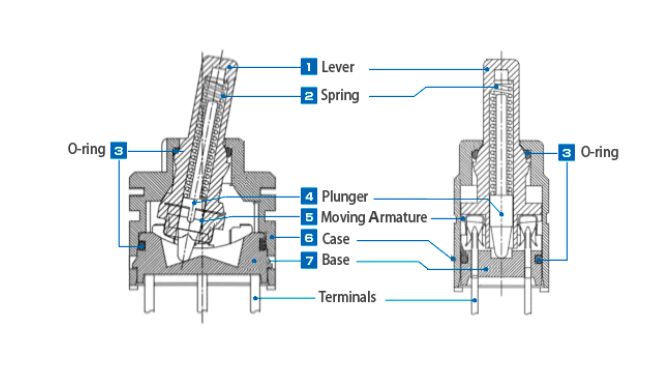

A standard toggle switch consists of several key components:

- Toggle lever/handle: The external part manipulated by the user

- Pivot mechanism: Allows the lever to move between positions

- Spring: Provides tension and tactile feedback

- Contacts: Metal components that connect or disconnect to complete or break the circuit

- Terminals: Connection points for external wiring

- Housing: Insulating body that contains and protects the internal components

Circuit Completion Process

When the toggle is moved to the “on” position, the internal contacts close, creating a conductive path that allows electrical current to flow through the circuit. Conversely, moving the toggle to the “off” position separates these contacts, breaking the circuit and stopping current flow.

In more complex toggle switches with multiple poles and throws, the movement of the toggle can simultaneously control multiple independent circuits or redirect current flow between different paths.

Toggle Switch Types by Contact Configuration

Toggle switches are classified according to their contact configurations, which determine how many circuits they can control and in how many ways. Understanding these configurations is crucial for selecting the right switch for specific applications.

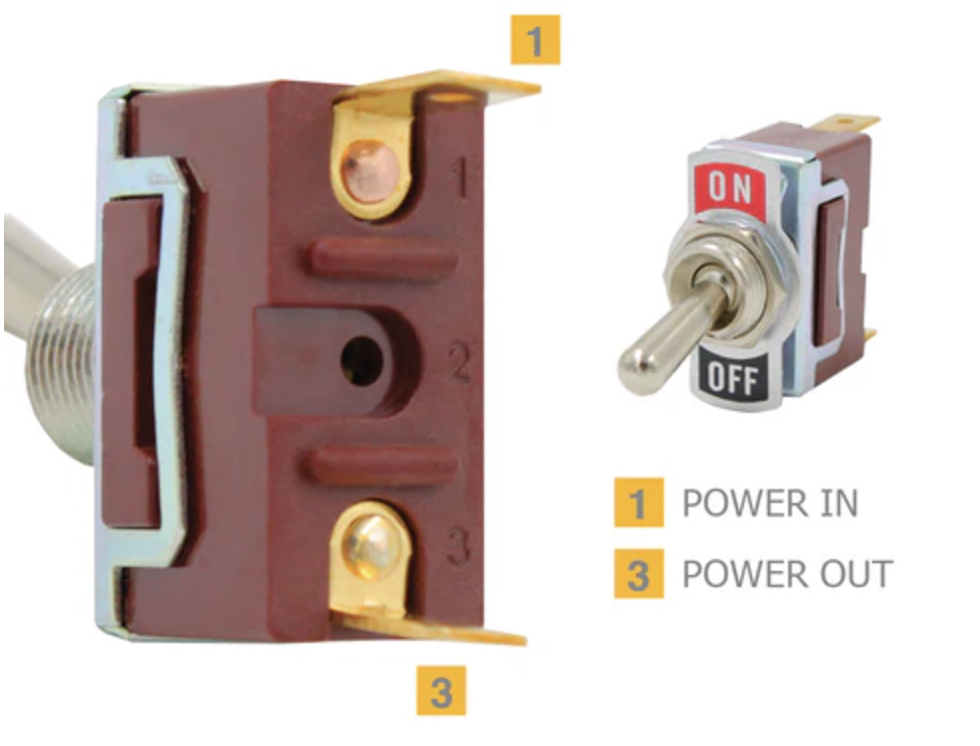

Single Pole Single Throw (SPST) Toggle Switches

Structure and Operation: SPST toggle switches have two terminals and control a single circuit with two positions: on and off. They are the simplest form of toggle switch, functioning much like a basic light switch.

Common Applications: These switches are ideal for applications requiring simple on/off control of a single circuit, such as:

- Power switches for electronic devices

- Lighting controls

- Simple motor controls

- Auxiliary systems in vehicles

Advantages and Limitations: SPST switches offer straightforward operation and are typically more economical than more complex configurations. However, they are limited to controlling just one circuit in a binary fashion.

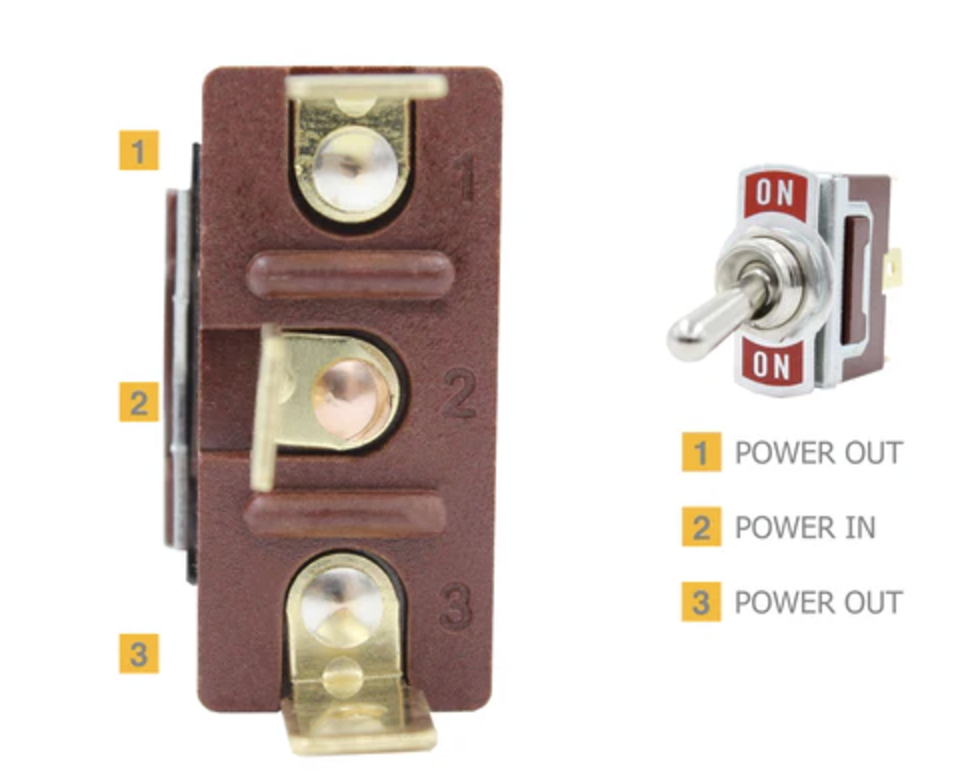

Single Pole Double Throw (SPDT) Toggle Switches

Structure and Operation: SPDT toggle switches have three terminals and control a single circuit with three positions. They can connect one terminal (the pole) to either of two other terminals (the throws), allowing the current to be directed along one of two paths.

Common Applications: These switches are perfect for applications requiring the redirection of current or the selection between two options:

- Reversing the direction of motors

- Switching between power sources

- Three-way lighting controls

- Signal routing in audio equipment

Advantages and Limitations: SPDT switches offer more versatility than SPST switches, allowing for more complex control schemes. However, they still control only a single circuit.

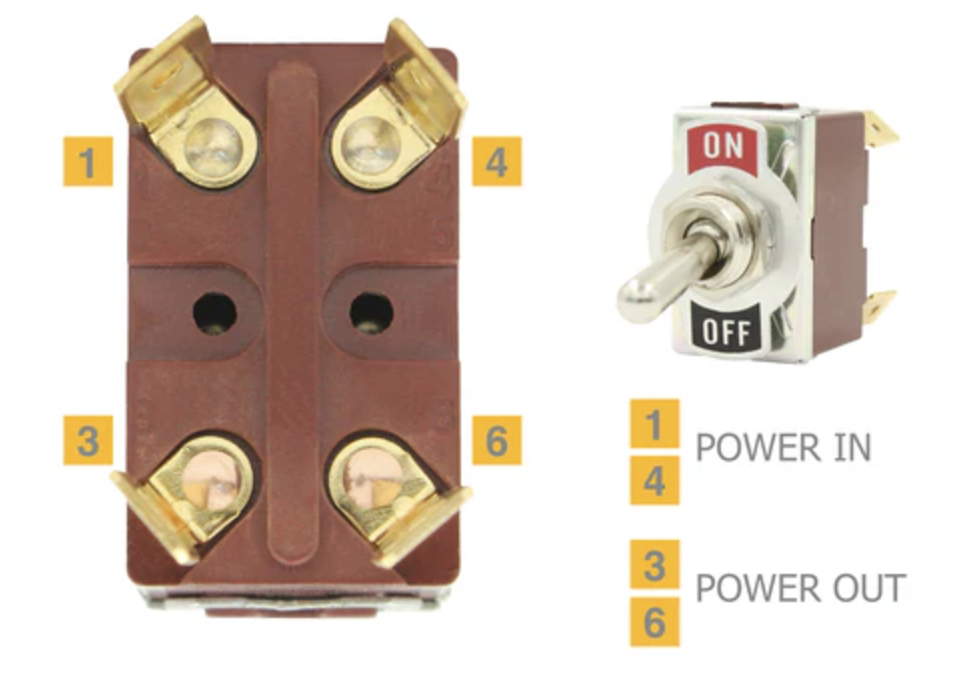

Double Pole Single Throw (DPST) Toggle Switches

Structure and Operation: DPST toggle switches have four terminals and control two separate circuits simultaneously, each with on/off functionality. They essentially function as two SPST switches operated by a single toggle.

Common Applications: These switches are ideal for applications requiring simultaneous control of two independent circuits:

- Controlling both hot and neutral lines in AC power applications

- Dual-voltage systems

- Redundant safety systems

- Simultaneous control of related functions

Advantages and Limitations: DPST switches allow for controlling multiple circuits with a single action, which can simplify user interfaces and ensure synchronized operation. However, they are physically larger and more expensive than single-pole variants.

Double Pole Double Throw (DPDT) Toggle Switches

Structure and Operation: DPDT toggle switches have six terminals and control two separate circuits, each with the ability to connect to one of two paths. They function as two SPDT switches operated by a single toggle.

Common Applications: These switches are suitable for complex applications requiring simultaneous control of multiple circuits with multiple options:

- H-bridge circuits for motor control

- Crossover networks in audio systems

- Complex signal routing

- Reversing polarity in two circuits simultaneously

Advantages and Limitations: DPDT switches offer the most versatility among standard toggle switch configurations, allowing for complex control schemes. However, they are the largest, most complex, and typically most expensive option.

Toggle Switch Types by Functionality

Beyond contact configurations, toggle switches are also categorized by their specific functional features and designs, each serving particular application needs.

Standard Toggle Switches

Standard toggle switches feature a simple lever mechanism without additional features. They are versatile, cost-effective solutions for general-purpose applications where basic switching functionality is sufficient.

LED Toggle Switches

Illumination Features: LED toggle switches incorporate light-emitting diodes within the switch design, typically in the lever itself. The illumination clearly indicates the switch’s status, enhancing visibility and user feedback.

Applications in Low-Light Environments: These switches are particularly valuable in:

- Automotive dashboards and control panels

- Aircraft cockpits

- Industrial control rooms

- Medical equipment

- Marine applications

- Any environment where visual confirmation of switch status is critical in low-light conditions

Toggle Switches with Protective Covers

Safety Features: These switches include protective caps or covers that prevent accidental activation or provide environmental protection. Some designs require lifting the cover before the switch can be toggled, adding a layer of safety.

Applications Requiring Protection: Common uses include:

- Emergency systems

- Military equipment

- Industrial machinery with critical functions

- Outdoor equipment exposed to elements

- Applications where accidental activation could be dangerous or costly

Waterproof/Sealed Toggle Switches

IP Ratings Explained: Ingress Protection (IP) ratings indicate a switch’s resistance to environmental factors. For example, an IP67-rated switch is completely protected against dust (6) and can withstand temporary immersion in water (7).

Environmental Protection Features: Sealed toggle switches incorporate gaskets, special housing designs, and sealed contacts to prevent the ingress of moisture, dust, and other contaminants. These features make them suitable for harsh environments where standard switches would quickly fail.

Miniature and Subminiature Toggle Switches

Size Specifications: Miniature toggle switches typically have bushing diameters of 6mm or less, while subminiature versions can be even smaller. These compact designs maintain functionality while significantly reducing the footprint.

Space-Saving Applications: These switches are essential in:

- Telecommunications equipment

- Medical devices

- Portable electronics

- Instrumentation

- Aerospace controls

- Any application where space constraints are significant

Toggle Switch Specifications and Parameters

Selecting the appropriate toggle switch requires careful consideration of various specifications and parameters that define its performance characteristics.

Electrical Specifications

Current Ratings: Toggle switches are rated for maximum current handling capability, typically expressed in amperes (A). Exceeding this rating can cause overheating, contact welding, or catastrophic failure.

Voltage Ratings: Maximum voltage ratings indicate the highest potential difference the switch can safely handle. Exceeding voltage ratings can cause arcing, insulation breakdown, or electrical hazards.

AC vs. DC Applications: Some toggle switches are rated differently for AC and DC applications due to the different electrical characteristics of these current types. DC applications often require higher contact separation distances to suppress arcing.

Contact Resistance: This parameter, measured in ohms, indicates the electrical resistance across the switch contacts when closed. Lower contact resistance results in less power loss and heat generation.

Mechanical Specifications

Actuator Types: Toggle switches come with various actuator designs, including:

- Standard bat handles

- Paddle handles

- Ball handles

- Short toggles

- Locking mechanisms

Mounting Options: Common mounting configurations include:

- Panel mount with threaded bushings

- PCB mount (through-hole or surface mount)

- Snap-in mounting

- Bracket mounting

Termination Types: Toggle switches offer various connection methods:

- Solder lugs

- Quick-connect terminals

- Screw terminals

- PCB pins

- Wire leads

Operating Force: This specification indicates the amount of force required to actuate the switch, typically measured in newtons (N) or gram-force (gf).

Environmental Specifications

Temperature Ranges: Toggle switches are rated for specific operating temperature ranges. Using a switch outside its rated range can lead to mechanical failure, contact issues, or insulation breakdown.

Humidity Tolerance: This specification indicates the maximum relative humidity level at which the switch can reliably operate.

Dust and Water Resistance: IP ratings define protection levels against solid particles and liquids. Higher IP ratings indicate better environmental protection.

Vibration Resistance: This parameter specifies the switch’s ability to maintain proper operation when subjected to mechanical vibration, critical in automotive, aerospace, and industrial applications.

Durability and Lifecycle

Expected Operational Cycles: This specification indicates the minimum number of operations (cycles) the switch is designed to perform before failure. Premium toggle switches may be rated for hundreds of thousands or even millions of cycles.

Failure Modes: Common failure mechanisms include contact wear, spring fatigue, mechanical breakage, and contamination.

Maintenance Requirements: While most toggle switches are designed to be maintenance-free, some applications may require periodic cleaning, inspection, or testing to ensure continued reliable operation.

Toggle Switch Materials and Construction

The materials used in toggle switch construction significantly impact their performance, durability, and suitability for specific applications.

Common Materials Used in Toggle Switch Construction

Metal Components: Contact materials are chosen for their electrical conductivity, corrosion resistance, and durability:

- Brass: Commonly used for terminals and structural components

- Copper: Excellent conductor used in current-carrying paths

- Silver: Superior conductivity, often used for contact surfaces

- Gold: Provides excellent corrosion resistance for low-current applications

- Nickel plating: Applied to improve corrosion resistance

Plastic Components: Housing and insulating materials are selected for their electrical insulation properties, temperature resistance, and mechanical strength:

- Thermoplastics: Used for general-purpose applications

- Thermosetting plastics: Offer superior heat resistance

- Polycarbonate: Provides excellent impact resistance

- Nylon: Offers good mechanical strength and chemical resistance

Insulating Materials: These materials prevent electrical shorting between components:

- Phenolic resins: Traditional insulating material with good heat resistance

- Ceramic: Used in high-temperature applications

- Silicone: Provides flexibility and excellent electrical insulation

Manufacturing Processes

Toggle switch production typically involves several manufacturing processes:

- Metal stamping and forming for contacts and terminals

- Plastic injection molding for housings and actuators

- Assembly of components

- Testing and quality control

- Packaging

Quality Control Standards

Reputable manufacturers implement rigorous quality control measures:

- 100% electrical testing

- Sample mechanical life testing

- Environmental stress testing

- Statistical process control

- Traceability systems

Compliance with Industry Regulations

Toggle switches used in commercial and industrial applications must comply with various regulatory standards:

- UL/CSA certification for North American markets

- CE marking for European markets

- RoHS compliance for hazardous substance restrictions

- Industry-specific standards for specialized applications

Industry Applications of Toggle Switches

Toggle switches find applications across numerous industries due to their reliability, simplicity, and versatility.

Industrial Applications

Control Panels: Toggle switches are extensively used in industrial control panels for machinery operation, process control, and system monitoring. Their robust design and clear visual indication make them ideal for environments where reliability is paramount.

Manufacturing Equipment: In manufacturing settings, toggle switches control various machine functions, safety systems, and operational modes. Their tactile feedback is valuable in environments where operators may be wearing gloves or working under challenging conditions.

Power Systems: Toggle switches serve critical roles in power distribution systems, backup power controls, and emergency shutdown systems. High-current versions are specifically designed for these demanding applications.

Commercial Applications

HVAC Systems: Commercial heating, ventilation, and air conditioning systems utilize toggle switches for mode selection, fan control, and system activation. Their reliability and simplicity make them ideal for these applications.

Restaurant Equipment: Commercial kitchen equipment, from ovens to food processors, incorporates toggle switches for their durability in high-temperature, high-humidity environments.

Retail Equipment: Point-of-sale systems, security equipment, and display lighting in retail environments often use toggle switches for their intuitive operation and long service life.

Automotive and Transportation

Vehicle Dashboards: Toggle switches control auxiliary systems in vehicles, including lighting, heating, air conditioning, and specialized equipment. Their tactile feedback allows drivers to operate them without looking away from the road.

Aircraft Control Panels: Aviation applications demand the highest reliability, making toggle switches with their mechanical simplicity and positive tactile feedback ideal for cockpit controls and systems management.

Marine Applications: Boats and ships use sealed toggle switches that can withstand exposure to moisture, salt spray, and extreme weather conditions while providing reliable control of navigation systems, lighting, and equipment.

Consumer Electronics

Home Appliances: Though less common in modern appliances, toggle switches are still found in specialized equipment where their mechanical reliability and intuitive operation are valued.

Audio Equipment: Professional and high-end consumer audio gear often features toggle switches for input selection, power control, and feature activation, appreciated for both their functionality and aesthetic appeal.

Gaming Devices: Specialty gaming controllers and simulation equipment use toggle switches to replicate real-world controls and provide immersive experiences.

Medical Equipment

Diagnostic Devices: Medical diagnostic equipment utilizes toggle switches for mode selection and function control, where reliability and clear operational status are essential.

Treatment Equipment: Medical treatment devices incorporate toggle switches in applications where simple, reliable control is needed, often with protective covers to prevent accidental activation.

Patient Monitoring Systems: Critical care monitoring equipment may use toggle switches for alarm settings, display options, and backup systems activation.

Telecommunications and Networking

Infrastructure Equipment: Telecommunications infrastructure relies on toggle switches for system configuration, backup power control, and maintenance functions.

Data Centers: Server rooms and data centers use toggle switches in power distribution units, cooling system controls, and emergency systems.

Communication Devices: Specialized communication equipment, particularly in military and emergency services applications, incorporates toggle switches for their reliability under adverse conditions.

Selection Guide for B2B Buyers

Choosing the right toggle switch for a specific application requires careful consideration of multiple factors to ensure optimal performance, reliability, and cost-effectiveness.

Key Factors to Consider When Selecting Toggle Switches

Electrical Requirements:

- Current and voltage ratings must meet or exceed the application’s demands

- AC or DC operation compatibility

- Inductive or resistive load handling capability

- Contact resistance appropriate for the application

Environmental Conditions:

- Operating temperature range

- Exposure to moisture, dust, or chemicals

- Vibration and shock requirements

- Indoor vs. outdoor use

Space Constraints:

- Available mounting space

- Panel thickness

- Clearance for operation

- Terminal access for wiring

Regulatory Compliance:

- Required certifications (UL, CSA, CE)

- Industry-specific standards

- RoHS and environmental compliance

- Flammability ratings

Cost Considerations

Initial Purchase Costs:

- Volume pricing considerations

- Standard vs. custom options

- Material quality trade-offs

- Supplier selection

Installation Costs:

- Mounting complexity

- Wiring requirements

- Specialized tools or processes

- Labor considerations

Maintenance and Replacement Costs:

- Expected service life

- Availability of replacement parts

- Ease of maintenance

- Downtime implications

Reliability Factors

Mean Time Between Failures:

- Mechanical life ratings

- Electrical life ratings

- Application-specific stress factors

- Safety margins

Warranty Considerations:

- Warranty terms and duration

- Exclusions and limitations

- Supplier support policies

- Return and replacement procedures

Supplier Reputation:

- Manufacturing quality history

- Industry presence and longevity

- Technical support capabilities

- Customer references

Customization Options

Custom Actuator Designs:

- Specialized handle shapes

- Extended toggles

- Locking mechanisms

- Ergonomic considerations

Special Markings:

- Custom legends

- Illumination colors

- Position indicators

- Branding options

Color Options:

- Housing colors

- Lever colors

- Color coding for function identification

- Compliance with industry standards

Installation and Maintenance Best Practices

Proper installation and maintenance of toggle switches are essential for ensuring reliable operation and maximizing service life.

Proper Installation Techniques

Panel Mounting:

- Verify panel thickness is within the switch’s specifications

- Ensure proper hole size and clearance

- Use appropriate hardware (nuts, lockwashers)

- Apply proper torque to mounting hardware

- Consider orientation for user accessibility and environmental protection

PCB Mounting:

- Verify pin alignment and spacing

- Ensure adequate support for mechanical forces

- Use appropriate soldering techniques

- Clean flux residues after soldering

- Consider strain relief for mechanical stress

Wiring Considerations:

- Use wire gauge appropriate for current requirements

- Ensure proper terminal connection (crimp, solder, or screw)

- Provide strain relief for connected wires

- Maintain proper clearance between terminals

- Consider insulation and protection for exposed terminals

Testing Procedures

After installation, toggle switches should be tested for:

- Proper mechanical operation

- Electrical continuity in all positions

- Insulation resistance

- Voltage drop across contacts

- Functional operation in the actual circuit

Maintenance Guidelines

Cleaning Recommendations:

- Use appropriate cleaning agents (typically isopropyl alcohol)

- Avoid excessive liquid that could enter the switch

- Clean external surfaces to remove contaminants

- For accessible contacts, compressed air can remove dust

Inspection Schedules:

- Visual inspection for damage or wear

- Mechanical operation check

- Electrical testing as appropriate

- Environmental seal integrity verification

Troubleshooting Common Issues:

- Intermittent operation: Check for loose connections or contact contamination

- High contact resistance: Inspect for corrosion or damage

- Mechanical binding: Check for physical damage or foreign objects

- Overheating: Verify current is within specifications

Replacement Indicators and Procedures

Signs that indicate a toggle switch may need replacement include:

- Erratic operation or intermittent connections

- Visible damage to housing or actuator

- Excessive heat during operation

- Failure to maintain position

- Unusual noise during operation

When replacing a toggle switch:

- Document the existing connections

- Select a compatible replacement

- Follow proper removal and installation procedures

- Test thoroughly before returning to service

Toggle Switch Innovations and Future Trends

The toggle switch market continues to evolve with technological advancements and changing industry needs.

Smart Toggle Switches

Traditional mechanical toggle switches are being enhanced with electronic capabilities:

- Integrated microcontrollers

- Status monitoring and reporting

- Remote operation capabilities

- Programmable functions

IoT Integration Capabilities

Modern toggle switches are increasingly designed with connectivity features:

- Wireless communication (Bluetooth, Wi-Fi, Zigbee)

- Integration with building automation systems

- Remote monitoring and control

- Data collection for predictive maintenance

Sustainable Materials and Manufacturing

Environmental considerations are driving changes in toggle switch production:

- Reduction or elimination of hazardous materials

- Recyclable components

- Energy-efficient manufacturing processes

- Extended product lifecycles

Miniaturization Trends

Ongoing efforts to reduce size while maintaining functionality include:

- Advanced materials allowing smaller components

- Improved manufacturing precision

- Integration of multiple functions

- Reduced power consumption allowing smaller contacts

Enhanced Durability Features

Innovations improving toggle switch reliability include:

- Advanced contact materials with reduced wear

- Improved sealing technologies

- Self-cleaning contact mechanisms

- Enhanced resistance to extreme environments

Market Projections for 2025-2030

Industry analysts project several trends in the toggle switch market:

- Continued growth in specialized industrial applications

- Integration with digital systems and IoT

- Increased demand for environmentally sealed versions

- Growth in aerospace and defense applications

- Expansion in emerging markets

Comparison with Alternative Switching Technologies

Understanding how toggle switches compare to other switching technologies helps in making informed selection decisions.

Toggle Switches vs. Rocker Switches

Similarities:

- Both provide on/off or multi-position control

- Similar electrical capabilities

- Manual operation

Differences:

- Toggle switches use a lever that moves in an arc

- Rocker switches pivot around a central point

- Rocker switches typically have a lower profile

- Toggle switches often provide better tactile feedback

Application Considerations:

- Toggle switches excel in applications requiring positive tactile feedback

- Rocker switches are preferred where a flush mounting is desired

- Toggle switches typically offer more configuration options

Similarities:

- Both provide manual control

- Available in momentary or maintained actions

- Similar electrical ratings available

Differences:

- Pushbuttons operate with linear motion

- Toggle switches provide visual indication of state

- Toggle switches typically require less force to actuate

- Pushbuttons often require less panel space

Application Considerations:

- Toggle switches are better for applications requiring visual state indication

- Pushbuttons excel in applications requiring frequent activation

- Toggle switches are often preferred for critical functions requiring deliberate action

Toggle Switches vs. Slide Switches

Similarities:

- Both provide visual indication of position

- Similar electrical capabilities

- Manual operation

Differences:

- Slide switches move in a linear path

- Toggle switches typically offer better tactile feedback

- Slide switches often have a lower profile

- Toggle switches generally offer higher current ratings

Application Considerations:

- Slide switches are preferred where space is limited

- Toggle switches excel in applications requiring definitive actuation

- Slide switches are often used for selection rather than on/off functions

Toggle Switches vs. Rotary Switches

Similarities:

- Both can control multiple circuits

- Both provide visual position indication

- Both offer maintained positions

Differences:

- Rotary switches can offer many more positions

- Toggle switches typically require less panel depth

- Rotary switches excel at function selection

- Toggle switches provide faster operation

Application Considerations:

- Rotary switches are preferred for multi-position selection

- Toggle switches excel in applications requiring quick state changes

- Rotary switches offer more complex circuit control options

Regulatory Standards and Compliance

Toggle switches used in commercial and industrial applications must comply with various regulatory standards to ensure safety, reliability, and environmental compatibility.

UL/CSA Standards

Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) certify toggle switches for North American markets:

- UL 1054: Standard for Special-Use Switches

- UL 508: Industrial Control Equipment

- CSA C22.2 No. 55: Special Use Switches

These standards address:

- Electrical safety

- Fire hazard prevention

- Performance requirements

- Construction standards

IEC Standards

The International Electrotechnical Commission (IEC) provides global standards:

- IEC 60947: Low-voltage switchgear and controlgear

- IEC 61058: Switches for appliances

These standards cover:

- Operating characteristics

- Electrical ratings

- Environmental performance

- Testing methodologies

IP Ratings Explained

Ingress Protection (IP) ratings consist of two digits:

- First digit (0-6): Protection against solid objects

- Second digit (0-9): Protection against liquids

Common ratings include:

- IP40: Protected against objects >1mm, no water protection

- IP65: Dust-tight and protected against water jets

- IP67: Dust-tight and protected against temporary immersion

- IP68: Dust-tight and protected against continuous immersion

RoHS Compliance

Restriction of Hazardous Substances (RoHS) directives limit the use of specific hazardous materials in electrical and electronic products:

- Lead (Pb)

- Mercury (Hg)

- Cadmium (Cd)

- Hexavalent chromium (Cr6+)

- Polybrominated biphenyls (PBB)

- Polybrominated diphenyl ethers (PBDE)

- Four different phthalates (DEHP, BBP, BBP, DIBP)

Industry-Specific Regulations

Various industries have additional requirements:

- Aerospace: AS9100 quality standards

- Automotive: ISO/TS 16949 quality standards

- Medical: ISO 13485 and FDA requirements

- Military: MIL-STD specifications

Conclusion

Toggle switches remain essential components in countless applications across diverse industries. Their mechanical simplicity, reliability, and intuitive operation ensure they will continue to play a vital role in electrical and electronic systems for years to come.

The selection of the appropriate toggle switch for a specific application requires careful consideration of electrical requirements, environmental conditions, mechanical specifications, and regulatory compliance. By understanding the various types, features, and performance parameters of toggle switches, B2B buyers can make informed decisions that optimize performance, reliability, and cost-effectiveness.

As technology continues to evolve, toggle switches are adapting with enhanced features, improved materials, and integration with digital systems. However, their fundamental value proposition—providing reliable, tactile control with clear visual indication—remains as relevant today as when they were first introduced.

For B2B professionals seeking toggle switches for their applications, we recommend:

- Clearly defining your application requirements

- Consulting with reputable manufacturers or distributors

- Considering the total cost of ownership, not just purchase price

- Ensuring compliance with relevant standards and regulations

- Testing samples in your specific application before full implementation

By following these recommendations and applying the knowledge provided in this guide, you can confidently select the optimal toggle switch solution for your specific needs.

Glossary of Terms

Actuator: The part of the switch that is physically moved by the user to change the switch state.

Contact Bounce: The rapid making and breaking of electrical contact that occurs when switch contacts close.

Contact Resistance: The electrical resistance across closed switch contacts.

DPDT: Double Pole, Double Throw – a switch configuration controlling two independent circuits, each with two possible positions.

DPST: Double Pole, Single Throw – a switch configuration controlling two independent circuits, each with on/off functionality.

Dielectric Strength: The maximum electric field a material can withstand without breaking down.

Ingress Protection (IP): A standard that classifies the degree of protection against intrusion of solid objects, dust, and water.

Maintained Contact: A switch that remains in its last position until physically moved again.

Momentary Contact: A switch that returns to its normal position when released.

Pole: A set of contacts that controls one circuit.

RoHS: Restriction of Hazardous Substances – a directive restricting the use of specific hazardous materials in electrical and electronic products.

SPDT: Single Pole, Double Throw – a switch configuration controlling one circuit with two possible positions.

SPST: Single Pole, Single Throw – a switch configuration controlling one circuit with on/off functionality.

Throw: A position to which a switch can be set.

UL: Underwriters Laboratories – a safety certification organization.

Voltage Drop: The reduction in voltage across a switch’s closed contacts due to contact resistance.