Introduction to the Ultimate Guide to Rocker Switches

Rocker switches are essential components in various electronic devices, offering intuitive control and reliable performance. This ultimate guide explores the different types, applications, and benefits of rocker switches, helping you choose the right one for your needs. Whether for home, automotive, or industrial use, this guide has you covered.

The issues that everyone is most concerned about

Lifespan and performance in harsh environments.

Voltage and current compliance.

Protection in outdoor/industrial settings.

Adherence to international standards.

Comfort and clear operation status.

Appearance, color, shape, and material.

Custom colors, symbols, and configurations.

Technical support and after-sales service.

What is a Rocker Switch?

A rocker switches is an electrical switch that rocks back and forth when pressed, which means one side of the switch is raised while the other side is depressed. This action either opens or closes the electrical circuit. Rocker switches are commonly used for power switches on electronic devices and are easily identifiable by their shallow-dipping seesaw mechanism.

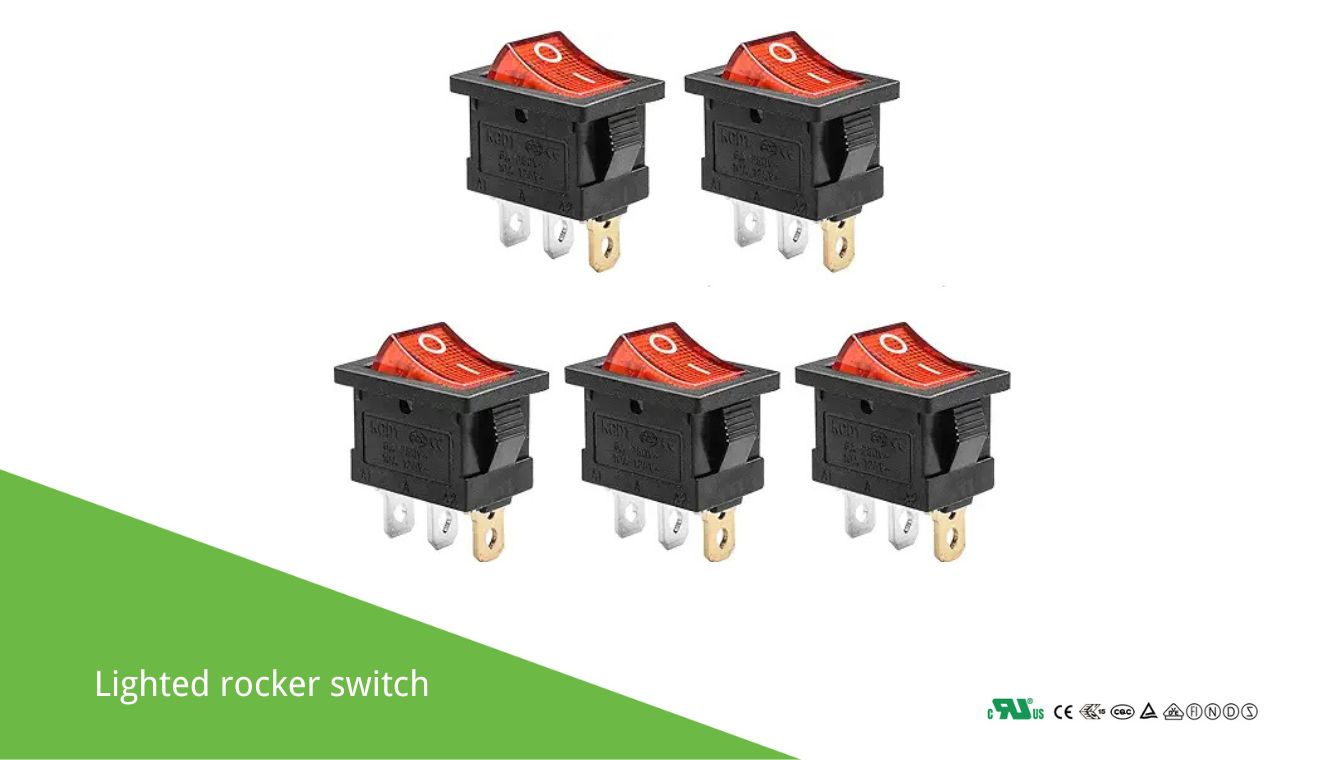

They often come with an “on” and “off” label and may sometimes include an indicator light to show when the circuit is active. They can be designed for various applications, including low-voltage electronics or high-current mains circuits, and can come in various sizes, shapes, and colors to suit different functions and aesthetics.

How Does a Rocker Switch Work?

The operation of a rocker switch is based on a simple mechanical principle. When the switch is pressed, one end of the switch moves down while the other end moves up, resembling a seesaw. This action either connects or disconnects electrical contacts within the switch, thereby controlling the flow of current in the circuit.

Inside the rocker switch, there is a lever mechanism that pivots around a central point. When the lever is pressed down, it closes the circuit, allowing current to flow. Conversely, pressing the lever in the opposite direction opens the circuit, stopping the current flow. This toggling action is straightforward and requires minimal force to operate.

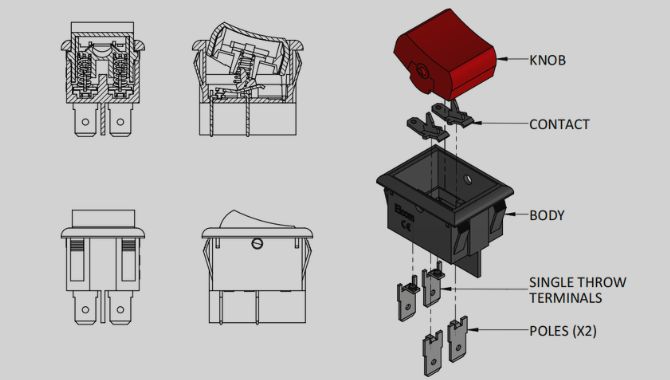

Internal Components

Rocker switches typically consist of several key components:

- Operation Button: The part that users press to switch between states.

- Spring Mechanism: This component ensures that the switch returns to its original position after being pressed.

- Electrical Contacts: These are the conductive parts that either connect or separate when the switch is toggled.

- Terminals: Points where wires connect to the switch, allowing current to enter and exit.

Types of switches

Rocker Switch ON OFF

Rocker Switch ON ON

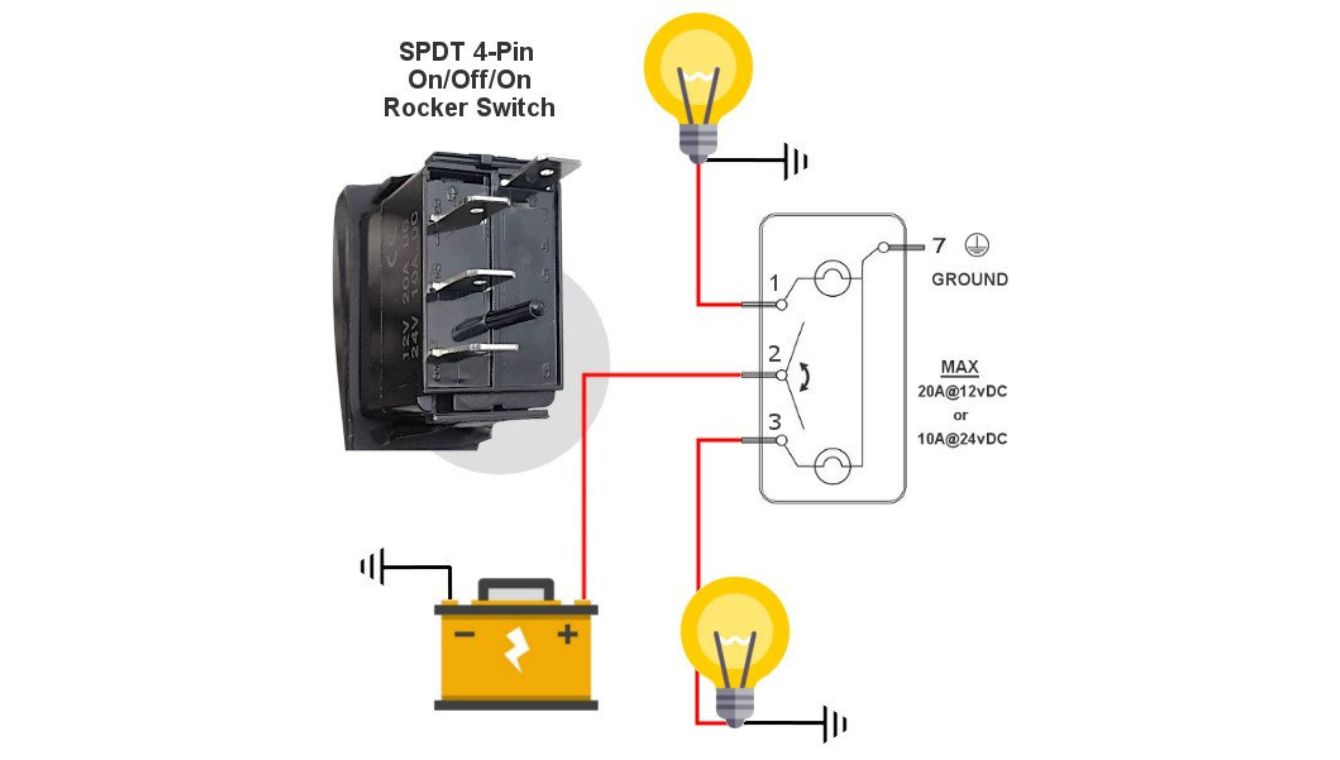

Rocker Switch (ON) OFF ON

Rocker Switch (ON) OFF (ON)

Rocker Switch OFF ON ON

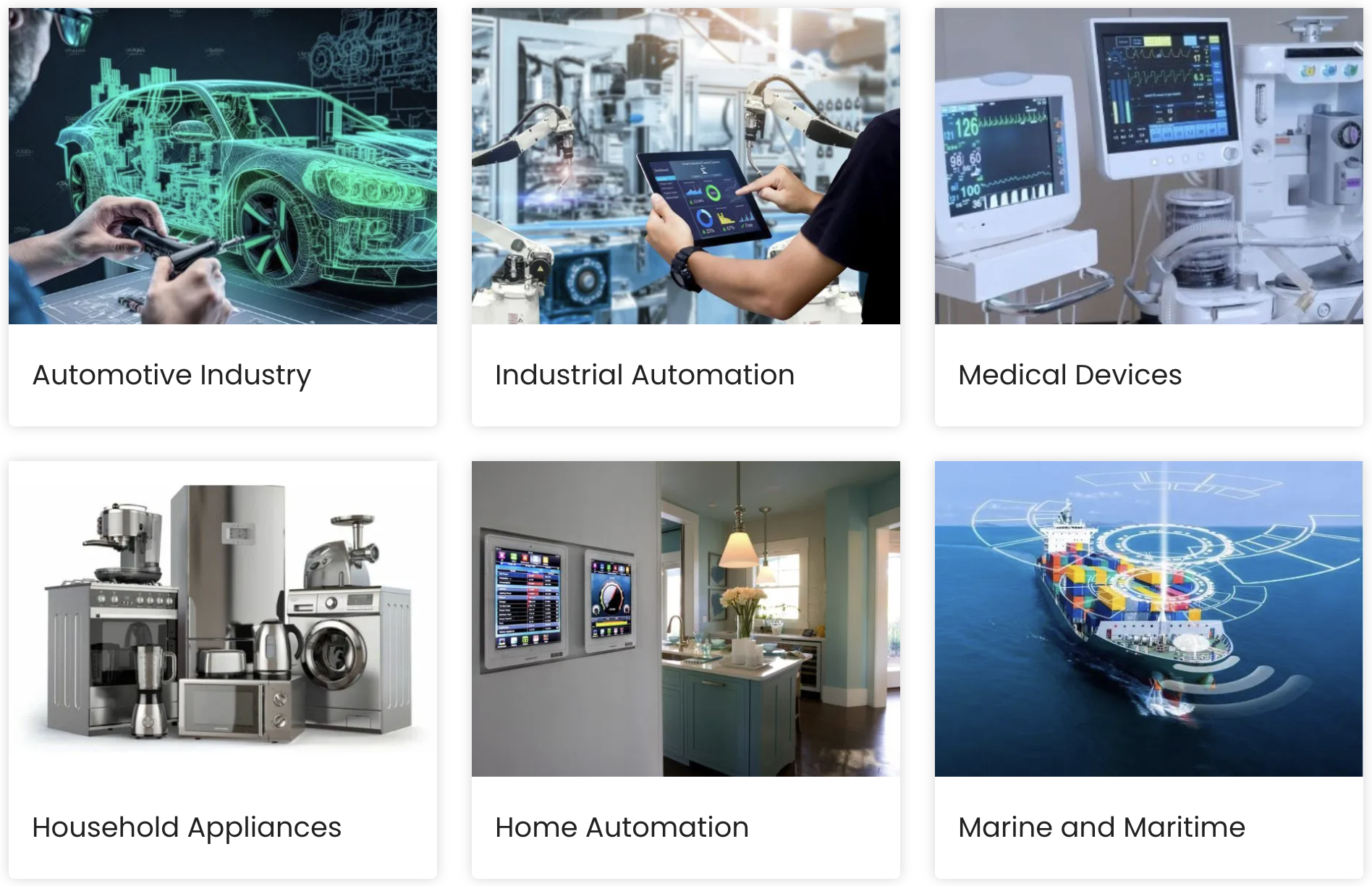

Top Applications for Rocker Switches

Rocker switches are versatile control devices used in various applications, including home appliances, automotive, and industrial equipment.

Our switches are designed for durability, offering high reliability and a long lifespan. With customizable options and a wide range of styles, they are perfect for any project.

Choose our rocker switches for superior performance and safety, backed by quality manufacturing and competitive pricing. Explore our innovative solutions today!

What Are Marine-Grade Rocker Switches?

Marine-grade rocker switches are specially designed for use in marine environments. They feature corrosion-resistant materials and waterproof seals to withstand harsh conditions, ensuring reliability on boats and other vessels.

Our switches offer durability, easy installation, and a variety of designs to fit any application.

With strict quality control and competitive pricing, our products guarantee long-lasting performance and customer satisfaction. Explore our range today!

Rocker Switch Boot

A switch waterproof cover is a protective casing designed to shield an electrical switch from water and other environmental elements. This cover helps prevent moisture ingress that can lead to electrical shorts or corrosion of the switch components.

Such covers are commonly used in outdoor settings, bathrooms, or in industrial environments where water exposure is likely. They often feature a durable plastic or rubber material and may come as a flip-up lid or a sealed enclosure, ensuring that the switch remains functional and safe to operate even when exposed to water.

Waterproof covers are essential for maintaining the safety and longevity of electrical switches in harsh or wet conditions.

What are Rocker Switches Used for?

Rocker switches are user-interface controls commonly used in electrical power systems to toggle the flow of electricity between on and off positions. They are named for their rocking motion when pressed, one side of the switch protrudes while the other retracts. Their design allows for easy operation, offering a visible indication of status—up or down, on or off. Rocker switches are versatile and found in a variety of applications, from consumer electronics and appliances to industrial machinery and automotive panels. They often come with markings or illuminated indicators to signal their state and can vary in size, current rating, and protection level to suit specific needs.

Things to Consider When Selecting a Rocker Switch

When choosing a rocker switch, consider factors like voltage rating, size, and aesthetics. Our switches are high-quality, durable, and designed for various applications. We offer customizable options, including colors and markings, to fit your needs. Our manufacturing process ensures reliability and safety, making us a trusted partner. Explore our extensive range to find the perfect switch for your project!

Sub-Mini Rocker Switches

Rating: 3A 125VAC; 1.5A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1000VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥50,000 Cycles

Miniature Rocker Switches

Rating: 6A 125VAC; 3A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1500VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥50,000 Cycles

Medium Rocker Switches

Rating: 10A 125VAC; 6A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1500VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥50,000 Cycles

Round Rocker Switch

Rating: 15A 125VAC; 10A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1500VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥10,000 Cycles

30 Amp Rocker Switches

Rating: 30A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1500VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥50,000 Cycles

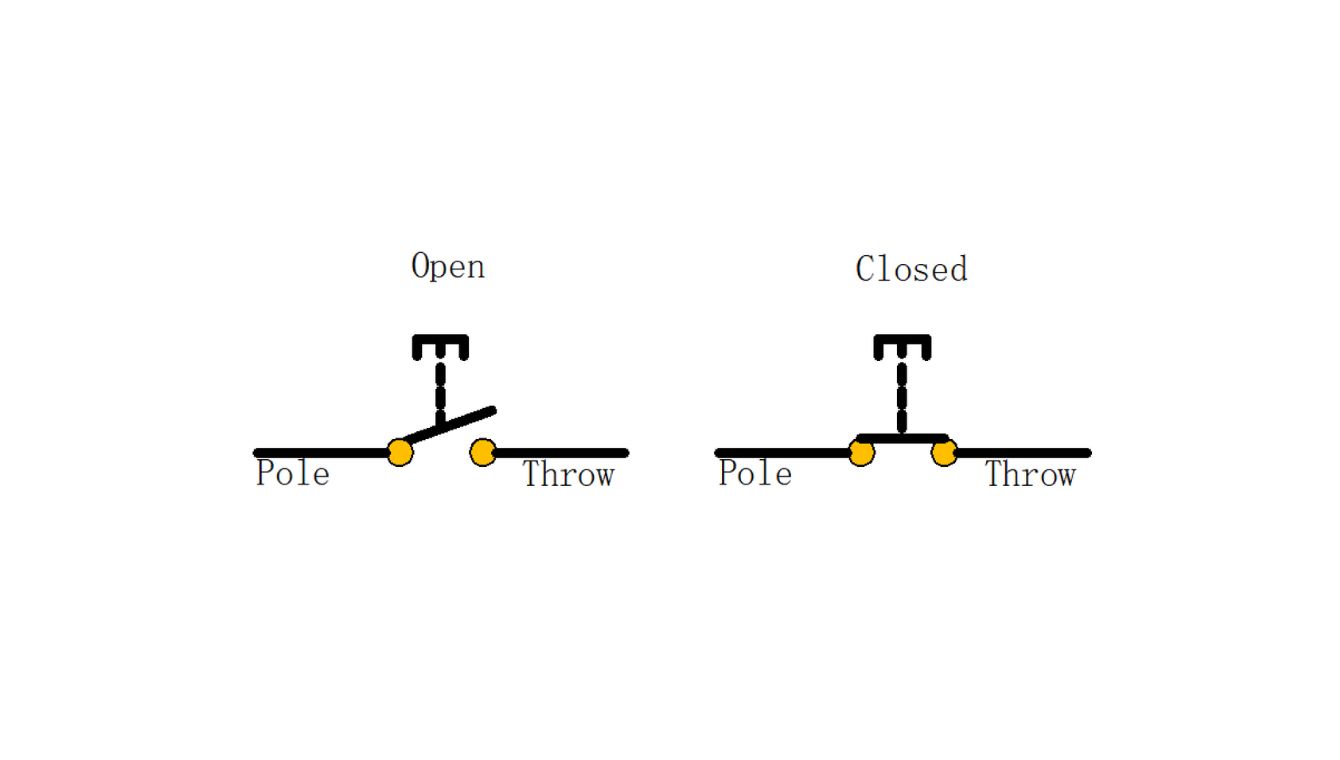

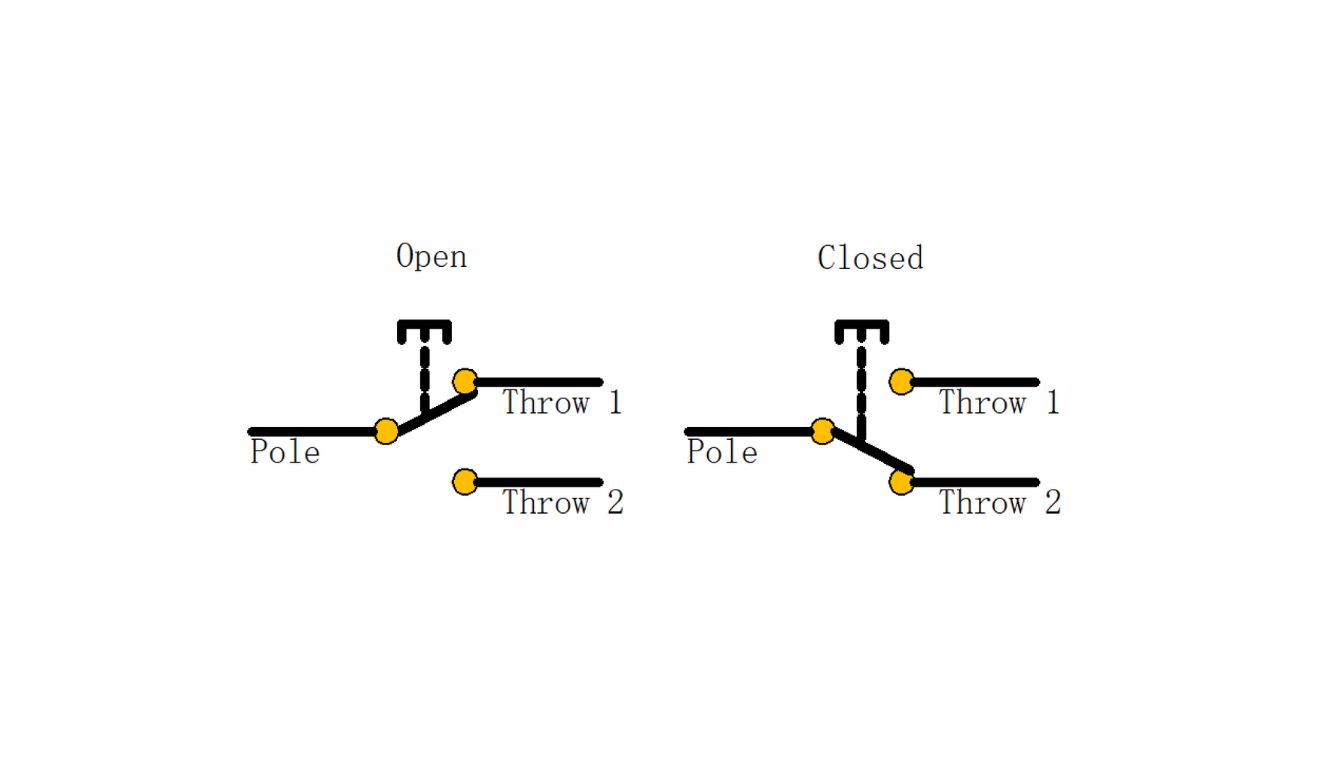

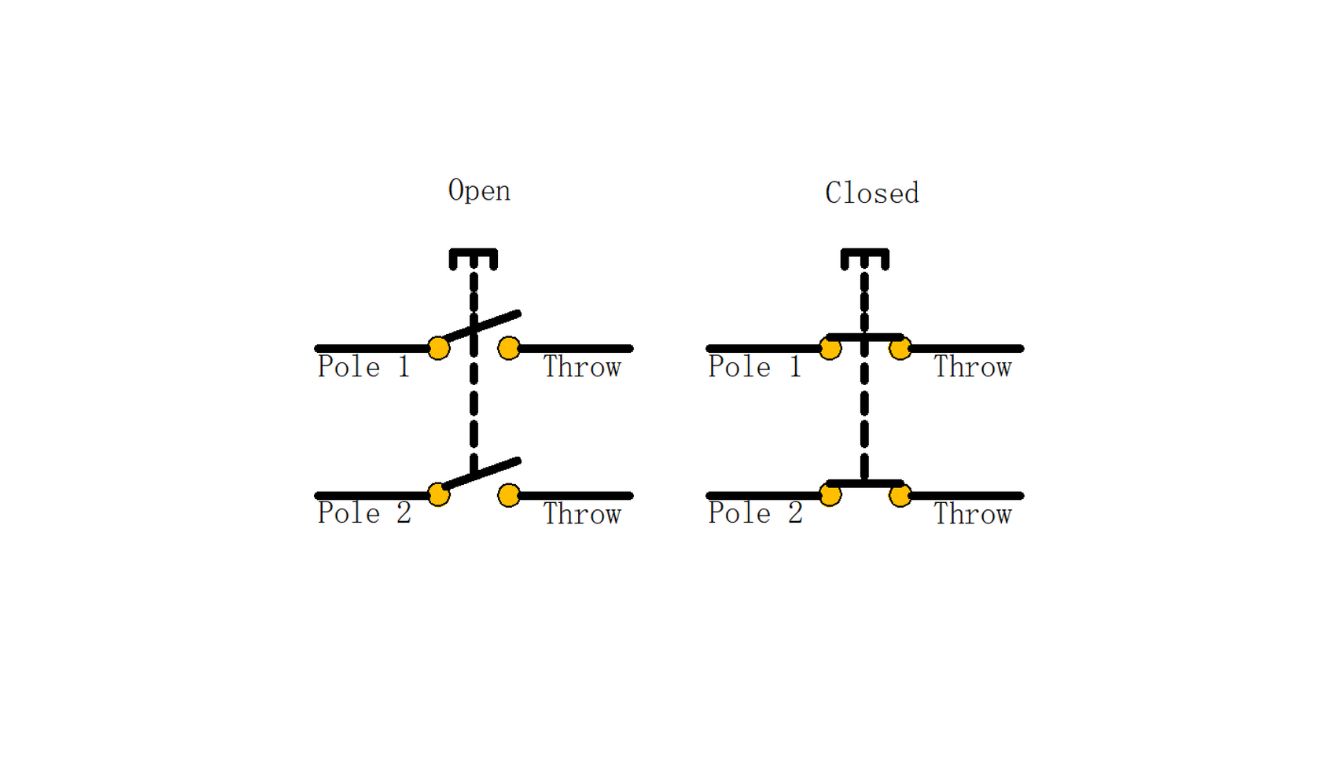

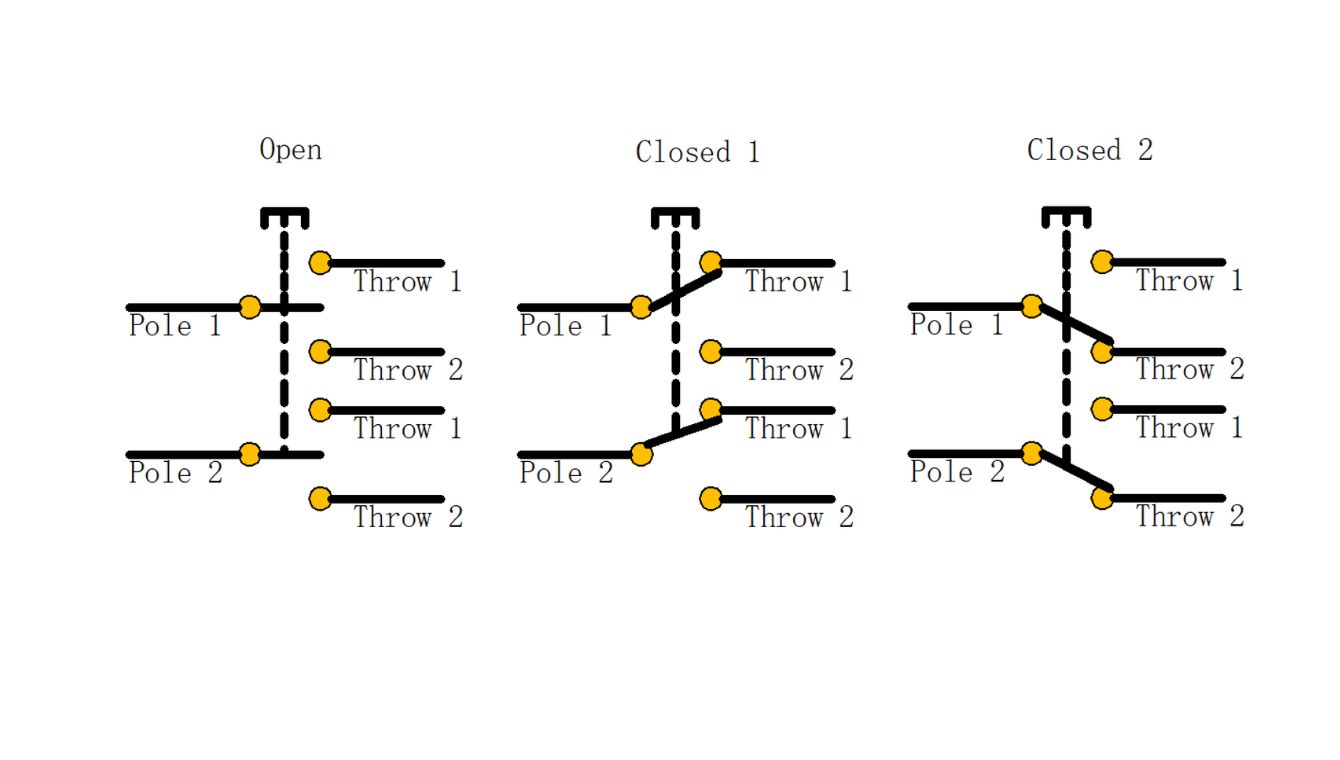

Rocker Switch Positions: Poles and Throws

Rocker Switches VS Toggle Switches

Rocker switches operate using a seesaw motion; when one side is pressed, the other rises. They often have a “on” and “off” label and can easily be operated with a simple push, making them user-friendly. Rocker switches are typically used for household appliances and are favored for their sleek design which allows them to sit flush with the surface they are mounted on.

Toggle switches feature a lever that is manually pushed up or down to open or close the electrical circuit. They provide a clear visual indication of whether the switch is in the “on” or “off” position and are commonly used in industrial and automotive applications due to their durability and straightforward operation. Toggle switches can handle a variety of electrical loads and are available in many different styles and sizes.

More Related Articles

Learn how to read and interpret rocker switch wiring diagrams effectively. This guide provides clear explanations, tips, and visual aids to help you understand the connections and functions of rocker switches in various applications. Ideal for beginners and DIY enthusiasts.

Explore the differences between normally open (NO) and normally closed (NC) switches. Understand their functions, applications, and how they operate in electrical circuits. Ideal for beginners and professionals alike.

Related Product

7 Considerations for Choosing The Right Rocker Switch

Selecting the right rocker switch is essential for ensuring optimal performance and reliability in your electrical and electronic systems. Whether you’re working on an industrial project or a household application, choosing the right switch can make a significant difference. Here’s a guide to help you make an informed decision by considering the following factors:

Rocker switches come in various types, such as single-pole/single-throw (SPST), single-pole/double-throw (SPDT), and double-pole/double-throw (DPDT). The type you choose should be based on your application needs. For instance:

- SPST: Suitable for simple on/off control.

- SPDT: Ideal for switching between two circuits.

- DPDT: Used for more complex operations, allowing control of two circuits with one switch.

The current rating is a crucial factor when choosing a rocker switch. It specifies the maximum current the switch can handle without getting damaged. If a switch is used in a circuit where the current exceeds its rating, it could cause overheating, contact damage, or even failure. Ensure the rocker switch you select has a current rating that meets or exceeds your application’s requirements.

Similar to the current rating, the voltage rating indicates the maximum voltage the switch can safely handle. It’s important to match the switch’s voltage rating with the application’s voltage requirements. A mismatch could lead to electrical failures or hazards. Always check both the current and voltage ratings before making your choice.

Consider the environmental conditions where the switch will be used. Factors such as exposure to moisture, dust, extreme temperatures, and vibrations can impact the switch’s performance. Choose a rocker switch with an appropriate IP rating to ensure it is protected against these environmental factors. For outdoor or industrial settings, a higher IP rating is recommended.

The actuator style of a rocker switch refers to the shape and feel of the switch’s control mechanism. Rocker switches come in various actuator styles, such as standard, illuminated, and custom shapes. The choice of actuator should match the user interface design and ergonomic needs of the application. For example, illuminated rockers are helpful for low-light environments or where visual feedback is necessary.

Rocker switches are available in different mounting styles, including snap-in, screw-mount, and PCB mount. The choice of mounting style depends on the installation requirements and space constraints of your application. Snap-in mounts offer easy installation, while screw mounts provide a more secure and stable setup.

The durability of a rocker switch is often determined by its mechanical and electrical life. This refers to how many times the switch can be operated before it starts to fail. For applications that require frequent switching, select a rocker switch rated for a high number of cycles. Additionally, consider switches made from high-quality materials to ensure long-term reliability.