Trigger switches are a vital component of saws that play a critical role in both the safety and efficiency of these machines. This comprehensive guide will delve into the workings of trigger switches, their significance in ensuring safe operation, and how they can improve the overall performance of your saw. Whether you are a seasoned professional or an amateur woodworker, understanding trigger switches is essential for maintaining a high level of safety when using power saws.

In this article, we will examine how trigger switches function in detail, including their importance in preventing accidents while operating saws. Additionally, we will explore the various benefits that come with using trigger switches to increase efficiency during cutting tasks.

By providing maintenance tips and best practices for using saws with trigger switches, this guide aims to equip readers with all the knowledge necessary to operate these machines safely and efficiently.

Introduction Trigger Switches

This discussion will provide a comprehensive guide on trigger switches for saws, focusing on their safety and efficiency.

Trigger switches are an essential component of any power tool, as they enable the user to control the operation of the saw.

It is important to understand how these switches work and how to use them properly in order to maximize both safety and productivity in woodworking tasks.

Brief overview of the topic

The introductory section provides a concise and informative overview of the topic at hand, allowing readers to gain a general understanding of the subject matter. In this case, the focus is on trigger switches for saws and how they impact both safety and efficiency in woodworking.

Trigger switches are an essential component of any power tool, responsible for initiating and controlling its operation. They are particularly important for saws because they determine when the blade starts and stops moving.

When it comes to safety, trigger switches play a critical role in preventing accidents and injuries from occurring. A well-designed switch should be easy to operate with one hand, allowing users to maintain control over the saw while keeping their other hand free to stabilize workpieces or make adjustments as needed. Additionally, trigger switches should be designed in such a way that accidental start-ups are minimized or eliminated entirely. This can include features like lock-out mechanisms or safety guards that prevent fingers from accidentally coming into contact with the blade during use.

On the other hand, efficient trigger switches can help improve overall productivity by reducing downtime between cuts and minimizing operator fatigue. By choosing a saw with a well-designed trigger switch, woodworkers can achieve faster cutting speeds without sacrificing precision or control over their workpiece.

Importance of trigger switches for saws

Understanding the significance of carefully selecting a well-designed trigger mechanism for power tools such as saws can greatly impact both the safety and productivity of woodworking operations. The trigger switch is an essential component that controls the activation and deactivation of the saw blade, allowing the operator to have complete control over the tool’s functionality. It is crucial to ensure that the trigger switch is responsive, functional, and easy to use in order to avoid any accidents or injuries.

The importance of a reliable trigger switch cannot be overstated when it comes to ensuring safety while operating saws. A malfunctioning or poorly designed trigger switch can lead to accidental start-ups, which can cause serious bodily harm or property damage.

Additionally, a faulty trigger switch can also lead to operational inefficiencies, which could result in poor quality cuts and wasted materials. Therefore, investing in high-quality triggers switches that are ergonomically designed can help increase safety levels while improving overall productivity during woodworking tasks.

2. What are Trigger Switches?

Trigger switches are an essential component of power saws. They act as a control mechanism that enables the operator to start and stop the blade’s movement.

A trigger switch is usually located on the handle of the saw, allowing for easy access and operation. There are several types of trigger switches available in the market, each with its own unique features and benefits.

Definition of Trigger Switches

This section provides a clear and concise explanation of the mechanism used to control the activation and deactivation of power tools, which is crucial for ensuring safe and efficient operation in various industrial settings.

A trigger switch is a type of power tool switch that allows the user to turn on or off the device by squeezing or releasing a lever. This safety feature helps prevent accidental activation, as it requires intentional pressure applied to the trigger before the saw starts operating.

Another important component associated with trigger switches is blade guards. These safety features protect users from potential injuries caused by rotating blades, particularly when changing blades or conducting maintenance tasks.

Most modern saws come equipped with blade guards that automatically retract when cutting materials, reducing exposure to sharp edges and reducing risks of accidents. Additionally, some models also include electronic sensors that detect changes in blade speed or movement and automatically shut off power if they sense any irregularities in operation.

Different types of switch triggers available for saws

The following segment outlines various types of switch triggers accessible for power tools, each with unique features that cater to specific industrial needs and user preferences.

The most common trigger switch for saws is the standard trigger switch, which requires the operator to continuously press the button to keep the saw running. This type of switch ensures safety by preventing accidental starting of the saw, but can cause fatigue for prolonged use.

Another type of trigger switch is the paddle-type or ‘deadman’ switch that shuts off automatically when released, providing added safety features.

Additionally, some high-end saws come equipped with electric brakes that stop blade rotation immediately after releasing the trigger switch. This feature increases safety by reducing the risk of injury from accidentally touching a still spinning blade.

For enhanced efficiency in repetitive cutting tasks, some saws have a lock-on button that holds down the trigger without requiring continuous pressure from an operator. However, this function may pose risks if not adequately monitored during use.

Ultimately, careful consideration should be given to selecting a suitable trigger switch based on specific job requirements and worker experience levels to ensure both safety and efficiency in operation.

3. How do Trigger Switches Work?

This section discusses the working mechanism of trigger switches, including their components and the role of spring-loaded mechanisms.

Trigger switches are designed to control the flow of electricity in power tools by activating and deactivating them through a manual lever.

The switch comprises several components, including contacts, a spring-loaded mechanism, and an actuator that controls the movement of the contacts.

Explanation on how trigger switches work

Understanding the operational mechanics of a device’s activation mechanism is crucial for ensuring reliable and safe usage, particularly in high-risk contexts. Trigger switches are one such component that plays a vital role in power tools’ operation, including saws.

The trigger switch is essentially an electrical contact that controls current flow to the motor when activated by the operator. When a user presses the trigger switch, it completes an electrical circuit that allows current to flow from the power source to the motor, which powers up the saw blade. Conversely, releasing pressure on the trigger stops the current flow and shuts down the motor.

In terms of safety, trigger switches provide an essential function by allowing operators to control when and how much power is delivered to saw blades or other cutting implements. This feature enables users to stop or slow down their cuts as needed and can help prevent accidents caused by overzealous use of power tools. Additionally, many modern saws have safety features built into their trigger switches that prevent accidental activation or unwanted startups.

As for efficiency, having precise control over a saw’s speed through its trigger switch can improve cutting accuracy and reduce fatigue on operators who may otherwise struggle with heavy loads or awkward angles.

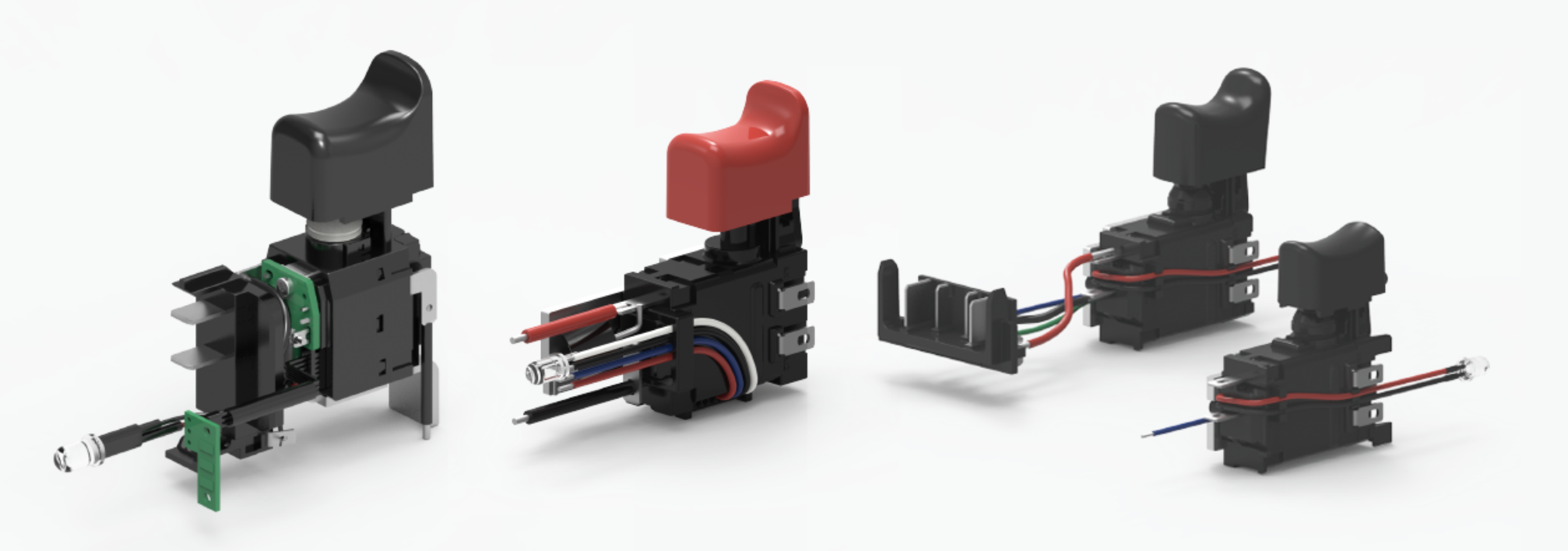

Components of a trigger switch

Exploring the constituent parts that make up a trigger switch can provide valuable insights into the inner workings of power tools and facilitate greater understanding of their operational functionality.

A trigger switch is made up of several components, including the trigger assembly, contacts, spring, and housing.

The trigger assembly refers to the part that is pressed or pulled to activate the switch.

Contacts are two metal plates that come into contact with each other when the trigger is engaged, allowing electricity to flow through and power on the tool.

The spring provides tension to reset the switch after it has been released.

Understanding these components can help prevent safety hazards associated with using power tools such as saws.

For example, malfunctioning contacts or springs may cause intermittent operation or result in unintended activation, leading to potential accidents.

Furthermore, some saws have a blade depth adjustment mechanism that uses a separate lever or knob which could also pose safety risks if not functioning correctly or overlooked by users while making adjustments.

Therefore, it is crucial for users to inspect their tools regularly before use and replace any worn-out parts promptly.

The role of the spring-loaded mechanism

The spring-loaded mechanism is a crucial component in the operation of power tools, providing the necessary tension to reset the trigger switch after it has been released, ensuring smooth and reliable performance. This mechanism plays an essential role in keeping users safe while operating power tools.

When the trigger button is released, the spring-loaded mechanism pulls back on the switch to prevent the saw from continuing to run. This safety feature protects users from potential injury caused by accidental activation of the tool.

In addition to preventing injury, this spring-loaded mechanism also promotes efficiency in saw operation. By ensuring that blades stop running as soon as pressure is removed from the trigger, users can save time and energy during use.

The spring’s tension must be carefully calibrated so that it provides enough force to return the trigger switch but not too much that it becomes difficult for users to operate smoothly. Overall, understanding how this critical component works can help ensure both safety and efficiency when using power tools like saws.

4. Importance of Trigger Switches in Safety

The importance of trigger switches in safety when using saws cannot be overstated.

Trigger switches enhance user safety by preventing accidental starting of the saw, which can lead to serious injury or damage.

Accidentally starting a saw without a trigger switch can cause kickbacks and other dangerous situations that could otherwise have been avoided.

Therefore, it is imperative that users understand the role of trigger switches in keeping them safe while operating power saws.

Explanation on how trigger switches enhance safety when using saws

Understanding the mechanisms that improve safety during saw operation is essential for every woodworker seeking to maintain a safe and secure working environment. Trigger switches are one of the most important safety features in power tools, especially saws. These devices enhance operator control over the tool and help reduce accidents, injuries, and property damage caused by improper handling.

Here are five ways trigger switches enhance safety when using saws:

- Power tool switch speed control: Trigger switches allow users to adjust the speed of their saw depending on their cutting needs. This feature reduces the likelihood of kickbacks or blade jams that could occur with a fixed-speed setting.

- Comfortable grip: The ergonomics of trigger switches provide users with a comfortable grip while operating the saw, which helps prevent fatigue or loss of control due to discomfort.

- Instant shut-off: In case of an emergency or accident, operators can immediately stop the blade from moving by releasing the trigger button. This instant shut-off feature minimizes injury risks and prevents further damage to workpieces or surroundings.

- Reduced accidental activation: Trigger switches require intentional pressure from operators to activate them, minimizing accidental starts that could result in serious harm.

- Blade visibility: When using a trigger switch-operated saw, users have better visibility of the blade’s position as compared to other types of power tools. This ensures greater accuracy and precision while performing cuts with sharp blades.

By incorporating these features into their design, trigger switches play a vital role in enhancing safety when using saws. Woodworkers should always prioritize safety concerns when operating any power tool.

Detailed description on how accidentally starting a saw without a trigger switch can lead to injury

Accidental activation of a power tool lacking a trigger switch can lead to serious injuries due to the absence of an instant shut-off feature and reduced operator control. Without this safety mechanism, users are at risk of losing control over the saw and experiencing kickback or blade contact with their body parts. The lack of a trigger switch also means that there is no way to immediately stop the saw if something goes wrong, which can result in severe lacerations, amputations, or even fatalities.

To emphasize the importance of trigger switches for saw safety, consider the following table:

| Injury Type | Description | Emotional Response |

|---|---|---|

| Laceration | A deep cut caused by a sharp object such as a saw blade | Fear and discomfort |

| Amputation | The loss of one or more limbs due to severe injury or trauma | Shock and horror |

| Fatality | Death resulting from an accident or injury while using a saw without proper safety features | Grief and sadness |

These injuries are not only physically painful but also emotionally distressing for both the victim and their loved ones. Therefore, it is crucial to prioritize safety when using power tools like saws by choosing models equipped with trigger switches. This simple yet effective feature can prevent accidents from happening and protect users from life-altering injuries.

Role in preventing kickbacks

Preventing kickbacks is a crucial aspect of power tool safety that requires careful consideration and attention to detail. Kickbacks occur when the saw’s blade suddenly stops or gets stuck while cutting, causing it to jerk back towards the operator with tremendous force. This can result in serious injuries, such as lacerations, broken bones, or even amputations.

To prevent kickbacks from occurring, it is important to use a saw with a trigger switch and follow safe operating procedures. Trigger switches play an essential role in preventing kickbacks by allowing the operator to control the speed and movement of the blade at all times. By releasing the trigger switch immediately after completing a cut, the operator can stop the blade from spinning and reduce the risk of kickback.

Additionally, using proper techniques such as keeping both hands on the saw at all times and maintaining a steady grip can further minimize risks associated with kickbacks. Ultimately, incorporating these precautions into one’s work habits can ensure maximum safety when operating power tools like saws.

5. Efficiency Benefits of Using Trigger Switches

The use of trigger switches can improve the efficiency of various tools and machines. Trigger switches provide a simple yet effective method for controlling the operation of equipment, allowing users to easily turn on or off devices with minimal effort.

By enabling quick and precise control over tool operation, trigger switches can save time and reduce errors in various applications.

Discussion on how using trigger switches can improve efficiency

The use of trigger switches in saws has been found to improve efficiency by providing easier turning off and on of the saw.

This feature is particularly useful when working with cordless saws as it also saves battery life.

Additionally, the smooth operation resulting from using trigger switches can lead to better quality cuts and reduced operator fatigue.

Easier turning off/on of the saw

Facilitating the act of powering down or starting up a saw can be accomplished through the implementation of an accessible and user-friendly mechanism, such as trigger switches. Trigger switches are not only useful for improving efficiency but also enhance safety measures on saws.

With these switches, operators can quickly turn off the machine if there is an emergency or risk involved during operation. Additionally, they don’t have to navigate complicated on/off buttons that could lead to accidents in case of an urgent situation. The ease of access provided by these switches thus allows for faster response times in dangerous situations, which ultimately increases safety standards in industries where saws are used regularly.

Furthermore, trigger switches make it easier to start up the saw again after being turned off, reducing downtime and increasing productivity levels for workers handling large-scale projects.

Overall, implementing trigger switches is a practical solution that enhances both safety and efficiency when working with saws.

Saves battery life (in cordless saws)

Conserving battery life is a crucial factor to consider when utilizing cordless saws, as it can significantly impact the duration of work time and overall productivity levels.

Trigger switches for saws can help save battery life in cordless units by allowing users to easily turn off the tool when it is not in use. This feature helps prevent unnecessary power drain and ensures that the battery lasts longer before needing a recharge or replacement.

In addition to improving efficiency, using trigger switches also enhances safety on worksites by minimizing the risk of accidental starts or injuries caused by leaving the saw running unattended.

Overall, incorporating trigger switches into cordless saws provides multiple benefits that contribute to better performance and safer operation.

Smooth operation

Achieving a smooth operation is an important consideration when using cordless saws, as it can impact the precision of cuts and overall quality of work.

A smooth operation reduces the risk of kickback or other accidents that may cause harm to the user or damage to materials being cut.

It also increases efficiency by reducing the time needed to make clean cuts without having to stop and adjust the saw frequently.

In order to achieve a smooth operation, it is important to select an appropriate trigger switch for the saw that allows for easy control and adjustment of speed.

Additionally, maintaining proper blade alignment and sharpness can help ensure a smooth cutting process.

Overall, prioritizing safety and efficiency through achieving a smooth operation can lead to better results in woodworking projects.

6. Maintenance Tips for your Saw’s Trigger Switch

This section will focus on providing maintenance tips for your saw’s trigger switch. Proper maintenance of the trigger switch is crucial to ensure its efficient functioning and longevity.

Two key aspects of trigger switch maintenance are cleaning and lubrication techniques, which will be discussed in detail below.

Cleaning tips

Maintaining cleanliness in the mechanism components of power tools can prolong their lifespan and prevent malfunctions, ensuring optimal performance during operation. This is especially important for saws with trigger switches as they are prone to dust accumulation, which can lead to safety hazards.

A build-up of debris and dust particles can interfere with the switch’s contact points, causing it to fail or even become stuck in the ‘on’ position. To avoid these risks, it is essential to clean your saw’s trigger switch regularly.

When cleaning a saw’s trigger switch, turn off the tool and unplug it from the power source before beginning any maintenance work. Use a soft-bristled brush (such as a toothbrush) or compressed air to remove any debris that has accumulated on the surface of the switch. Be sure not to use water or solvents as this could damage the electrical contacts and internal circuits.

Additionally, keep your blades clean by wiping them down after each use to prevent rust formation and ensure they remain sharp for efficient cutting.

By following these simple cleaning tips, you can help ensure your saw stays safe while operating at its best performance level.

Lubrication techniques

Proper lubrication techniques are crucial in ensuring the longevity and optimal performance of power tools, including saws. The moving parts of a saw, such as the trigger switches and spinning blade, require regular lubrication to prevent wear and tear. Before beginning any maintenance work on your saw, make sure to wear safety glasses to protect your eyes from any debris that may be dislodged during the process.

To begin lubricating your saw’s moving parts, start by identifying each part that needs oiling. For example, the trigger switch should be oiled lightly with a small amount of machine oil applied directly to its contact points. Similarly, the blade should be kept lubricated using a high-quality blade lube or silicone spray.

Apply the lube evenly over both sides of the blade while it is not in use and let it dry for at least 10 minutes before operating the saw again. By following these simple steps regularly, you can ensure that your saw operates smoothly and safely for years to come.

7. Best Practices When Using Saw with a Trigger Switch

When using a saw with a trigger switch, it is important to keep your fingers away from the trigger when not intending to use it. This is because accidental activation of the switch can cause serious injury or damage.

Additionally, double-checking to ensure that the switch is functioning correctly before use is also crucial in ensuring safety and efficiency during operation.

Following these best practices can help prevent accidents and enhance the overall performance of your saw.

Importance of keeping your fingers away from the trigger when not intending to use it

The act of keeping one’s fingers away from unintended activation points on machinery can prevent accidental injury and increase overall productivity. This is particularly important when using power tools with trigger switches, such as saws.

Trigger switches are designed to be easily activated by a user’s fingers, but this also means that accidental activation can occur if the tool is not handled properly.

To ensure safety and efficiency when using a saw with a trigger switch, it is crucial to keep one’s fingers away from the trigger when not intending to use it. This can be achieved by maintaining proper grip on the tool and positioning one’s hands in safe areas away from the trigger switch.

It is also important to never leave a saw unattended with its trigger switch exposed or within reach of anyone who may accidentally activate it.

By following these guidelines, users can reduce the risk of injury and improve their overall productivity while using this powerful tool.

Double-checking to ensure that the switch is functioning correctly before use

Prior to utilizing a power tool, it is advisable to thoroughly examine the machinery and ensure that its functional components are in proper working order.

One of the most important components when operating a saw is the trigger switch. The trigger switch serves as a safety mechanism that controls the operation of the saw. It allows for precise control over the cutting process and can help prevent accidents from occurring.

Double-checking to ensure that the switch is functioning correctly before use is critical for both safety and efficiency purposes. A malfunctioning trigger switch can lead to unintended cuts, damage to materials, or worse, injury.

Regular inspections of the trigger switch should be conducted by carefully examining its physical condition and testing its responsiveness before each use.

By taking these simple precautions, operators can help maintain their own safety while maximizing efficiency during work activities involving power tools such as saws.

8. Conclusion

This discussion will provide an overview of trigger switches and their importance in relation to saws. It will explain how trigger switches work, and highlight the reasons why they are critical for both safety and efficiency when using a saw.

Additionally, maintenance tips as well as best practices when using a saw with a trigger switch will be discussed. The information presented here is written in an academic style that remains objective and impersonal while avoiding personal pronouns.

An overview of what trigger switches are and their importance;

Understanding the function and significance of the mechanism that controls the activation and cessation of power in electrical devices is a crucial aspect of ensuring their proper operation and preventing accidents. One such mechanism is the trigger switch, which is commonly found in saws and other power tools.

Trigger switches are important because they allow for precise control over when the device is activated, making it safer to use. Trigger switches work by creating a closed circuit between the power source and motor of an electrical device. When pressure is applied to the trigger, it completes this circuit, allowing electricity to flow from the power source to the motor. Releasing pressure on the trigger opens up this circuit, stopping electricity from flowing to the motor.

This simple but effective design makes trigger switches an essential safety feature for saws and other power tools that require careful handling. By enabling users to precisely control when their saws turn on or off, trigger switches help prevent accidents and keep operators safe.

How they work; reasons why they’re critical for safety and efficiency;

The proper function and control of power in electrical devices are enhanced through an understanding of how trigger switches operate. Trigger switches, commonly found on power tools like saws, are critical to ensuring safety and efficiency during use. These switches allow the user to easily turn the tool on and off with a simple press of a button or lever.

In addition to their convenience, trigger switches play an important role in preventing accidents when using power tools. By requiring intentional activation, they prevent accidental activation that could cause injury or damage to property. Furthermore, some trigger switches have additional safety features like lock-on buttons that keep the tool running without having to hold down the switch continuously. As such, it is essential for users of power tools with trigger switches to understand their proper usage and follow safety tips when operating these tools.

| Safety Tips | Power Tools |

|---|---|

| Always wear appropriate personal protective equipment (PPE) such as goggles, gloves, and ear protection. | Saws |

| Keep your work area clean and free from clutter. | Drills |

| Ensure that your tools are properly maintained before each use. | Sanders |

| Never remove or disable any safety features on your power tools. | Grinders |

| Read the manufacturer’s instructions carefully before use. | Jigsaws |

Maintenance tips

In order to maximize the lifespan and performance of power tools, it is imperative for users to implement proper maintenance practices as outlined in the upcoming section.

For saws, regular maintenance procedures can prevent accidents and ensure optimal performance. Before using a saw, it is essential to inspect it thoroughly for any signs of wear and tear or damage. Any issues should be addressed immediately before operating the saw.

One critical aspect of maintaining a saw is keeping the blades sharp. Dull blades are not only inefficient but also pose safety risks. Regular cleaning of the blade and lubrication of moving parts can also extend their life span.

Additionally, users should follow manufacturer guidelines for replacing worn-out components such as belts or bearings to prevent potential hazards caused by malfunctioning equipment.

By properly maintaining their saws, users can ensure optimum efficiency while minimizing safety risks associated with faulty equipment.

Best practices when using a saw with a trigger switch

Maintaining a saw with a trigger switch is crucial in ensuring its longevity and functionality. However, proper maintenance alone does not guarantee safety when operating such tools. Best practices must also be observed to ensure that the user remains free from harm while using the saw.

When using a saw with a trigger switch, one must first ensure that they have read and understood the manufacturer’s instructions for use. These instructions will provide valuable information on how to properly handle and maintain your tool, as well as highlight any potential hazards that could arise during use.

Additionally, it is essential to wear appropriate protective gear such as eye goggles, earplugs, gloves, and steel-toed boots to minimize injury risk from flying debris or accidental slips.

In conclusion, following best practices when using saws with trigger switches goes beyond just maintaining the tool itself; it requires careful attention to safety measures like reading instruction manuals and wearing protective gear. Whether you’re an experienced carpenter or just starting out in DIY projects, observing these safety protocols will help you remain unharmed while working with these powerful tools.

Frequently Asked Questions

Can trigger switches be retrofitted onto older saw models?

Retrofitting trigger switches onto older saw models is a common practice among woodworkers and DIY enthusiasts. However, the feasibility of retrofitting depends on the type of switch and the age of the saw.

It is important to note that trigger switches are not a universal fit for all saws, so it is necessary to check if there are compatible aftermarket options available. Additionally, older saw models may require modifications or adjustments to accommodate the installation of a trigger switch, which can increase costs and potentially compromise safety if not done correctly.

Therefore, individuals should consult with professionals or conduct thorough research before attempting to retrofit a trigger switch onto an older saw model.

Are there any disadvantages to using trigger switches on saws?

The use of trigger switches on saws has both advantages and disadvantages.

On one hand, trigger switches can enhance safety by enabling the operator to easily turn off the saw in case of an emergency. This feature can prevent injury and damage to property.

Additionally, trigger switches can improve efficiency by allowing for quicker start-up times and easier control over the speed of the blade.

However, there are also potential downsides to using trigger switches, such as accidental triggering or inadvertent deactivation during use.

Furthermore, retrofitting older saw models with trigger switches may not always be possible or cost-effective.

Ultimately, the decision to utilize trigger switches on a saw should be based on a thorough consideration of all factors involved, including safety concerns and practicality for specific applications.

How do trigger switches differ from other safety features on saws?

Trigger switches are just one of the many safety features that can be found on saws. They differ from other safety features in that they require the user to continuously press a button or lever in order to keep the saw running. This feature is designed to prevent accidental starting and reduce the likelihood of injury.

Other safety features on saws may include blade brakes, anti-kickback devices, and dust collection systems. These features work together to ensure that users can operate their saws safely and efficiently with minimal risk of injury or damage to materials.

While trigger switches are an important component of saw safety, it is important for users to understand all of the different safety features available on their particular model in order to get the most out of their equipment while minimizing risks.

Can trigger switches be customized for different user preferences?

Customization of trigger switches for saws can be a crucial factor in improving user safety and efficiency. While some users may prefer a light touch to activate their saw, others may require a sturdier grip. Trigger switches can be calibrated to the specific needs of an individual user, allowing them to work with greater comfort and control.

Additionally, customization options such as hand placement, button shape and size, and tactile feedback can help users operate their saws more effectively. As such, manufacturers must consider various customization options when designing trigger switches to ensure that they meet the diverse needs of users while maintaining optimal safety standards.

Are there any regulations or standards for trigger switches on saws?

Regulations and standards exist for trigger switches on saws, which are designed to ensure user safety. These regulations vary depending on the country or region where the saw is being used.

In the United States, the Occupational Safety and Health Administration (OSHA) has established standards for saws that include requirements for trigger switch design and function. The European Union has similar regulations through its Machinery Directive, which sets requirements for machinery safety including trigger switches. Manufacturers must comply with these regulations to sell their products in these regions.

While specific requirements differ between countries, all aim to minimize accidents caused by faulty or poorly-designed trigger switches.

Conclusion

In conclusion, trigger switches are essential components in saws that contribute to both safety and efficiency. They work by controlling the power supply to the motor and enabling users to turn off the saw immediately in case of an emergency.

Proper maintenance is crucial for ensuring that the switch functions correctly at all times, including keeping it clean and replacing any faulty parts promptly. Furthermore, using best practices when operating a saw with a trigger switch can significantly reduce the likelihood of accidents.

Overall, trigger switches provide an excellent solution for addressing saw-related hazards while enhancing productivity levels. It is critical for individuals who use these types of tools regularly to understand how they function and their importance in maintaining safe working environments.

By following recommended guidelines, workers can minimize potential risks associated with using saws with trigger switches and ensure optimal operational performance.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd