How to Choose a High-Quality Toggle Switch for Your Application

Choose high-quality toggle switches for reliability and performance. Our switches feature durable materials, smooth operation, and excellent electrical conductivity. With customizable options, we cater to diverse applications, ensuring safety and longevity. As a leading in China, we offer competitive pricing, rigorous testing, and fast delivery. Trust our expertise to enhance your projects with superior toggle switches. Click to learn more!

Miniature Toggle Switch

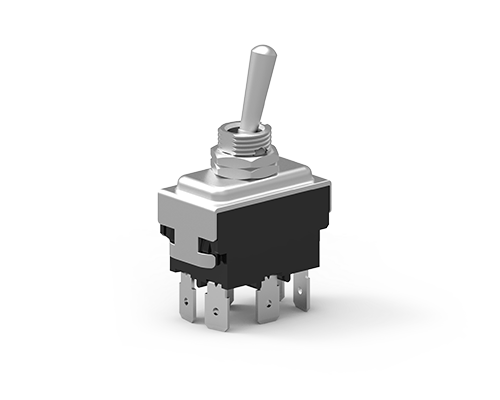

Medium Toggle Switch

Our medium toggle switches are designed for durability and precision, ensuring reliable performance in various applications. Manufactured in China with high-quality materials, our switches offer smooth operation and long-lasting functionality. Key features include robust construction, easy installation, and a sleek design. Choose us for competitive pricing, excellent quality control, and prompt customer service.

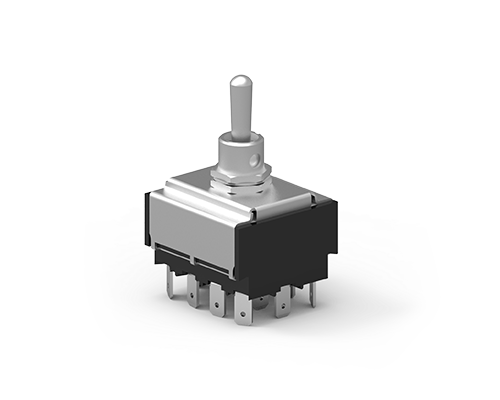

Heavy Duty Toggle Switch

A heavy-duty toggle switch is a robust electrical switch designed for high-load applications, ensuring reliable performance in challenging environments. Our switches feature durable materials, excellent conductivity, and a long lifespan, making them perfect for industrial and automotive use. With customizable options and rigorous quality control, we guarantee superior reliability and safety. Choose us for innovative solutions and outstanding customer support. Explore our range today!

Our Heavy Duty 12-volt Toggle Switch offers durability and reliability for various applications. Made with high-quality materials, it ensures long-lasting performance, easy installation, and excellent conductivity.

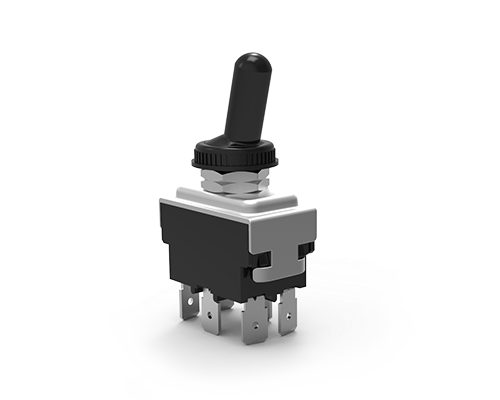

Toggle Switch Cover

- Flip-up covers that must be lifted before accessing the toggle

- Boot covers that allow operation while providing environmental protection

- Safety covers that require deliberate action to access the switch

Toggle Switch pin Diagram

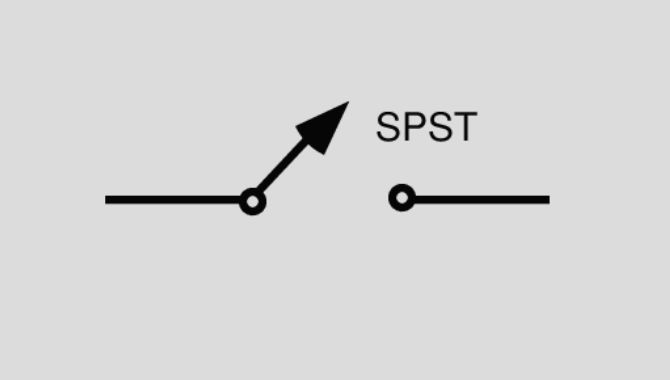

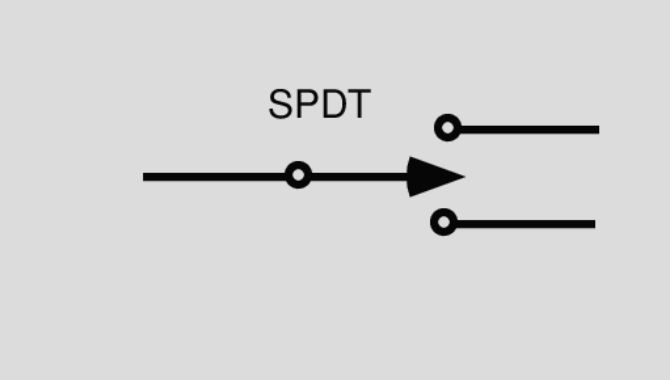

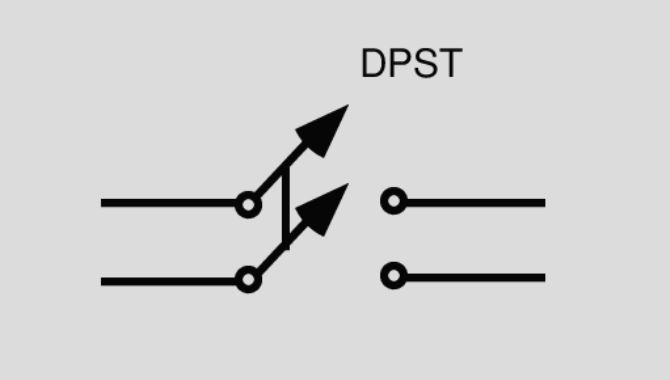

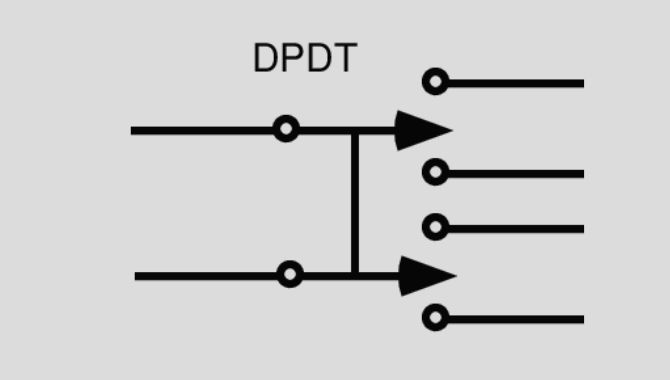

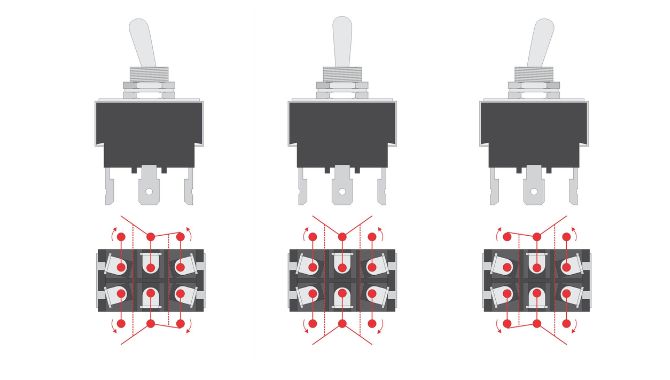

Classification by Pole & Throw Configuration

Toggle switches are essential electrical components used to control circuits. Our offerings include SPST (Single Pole Single Throw), SPDT (Single Pole Double Throw), DPST (Double Pole Single Throw), and DPDT (Double Pole Double Throw) switches.

Advantages of our products include high durability, reliable performance, and customizable designs. Manufactured with quality materials, our switches ensure long-lasting operation in various applications. Explore our range for innovative solutions that meet your needs!

With Full Product Certification

What are Toggle Switches?

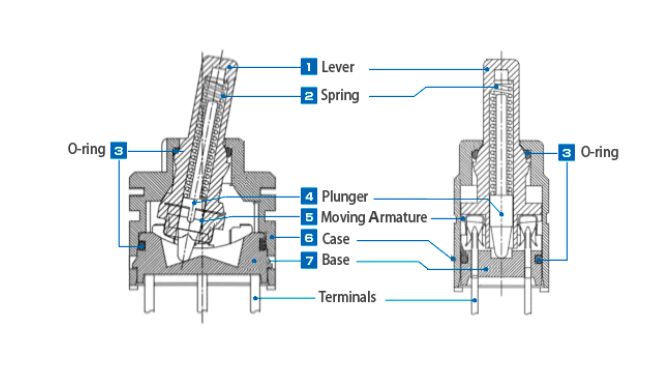

- Actuator (Lever or Handle): The external part that users manipulate to change the switch position. This lever typically pivots around a central point and can be moved between two or more positions.

- Contacts: The internal metal components that either connect or disconnect to complete or break the electrical circuit. These contacts are typically made from conductive metals like brass, copper, or silver, often plated with gold or nickel for better conductivity and corrosion resistance.

- Housing: The protective casing that contains the internal components and provides structural support. Housing materials vary depending on the application, with options including plastic, metal, or specialized materials for harsh environments.

How Do Toggle Switches Work?

Basic Working Principle

Circuit Control Mechanism

- Making Contact: When the switch is moved to the “on” position, the internal contacts physically touch each other, creating a conductive path for electricity to flow through the circuit.

- Breaking Contact: When moved to the “off” position, the contacts physically separate, creating an air gap that prevents electricity from flowing through the circuit.

Maintained vs. Momentary Operation

- Maintained Operation: In this standard configuration, the switch remains in whatever position it is placed until manually moved again. When flipped to the “on” position, it stays on until deliberately switched off.

- Momentary Operation: These specialized toggle switches include a spring mechanism that automatically returns the lever to its default position when released. They function similarly to a doorbell button, remaining activated only while held in position.

Advantages of Toggle Switches

Reliability and Durability

- Robust mechanical design: The simple internal mechanism has few points of failure.

- Self-cleaning action: The wiping motion of contacts helps maintain good electrical connections.

- Resistance to environmental factors: Quality toggle switches withstand dust, moisture, and temperature variations.

- Minimal maintenance requirements: Once installed, toggle switches typically require little or no maintenance throughout their operational life.

- Minimal training required: Users intuitively understand how to operate toggle switches.

- Unambiguous states: The physical position of the toggle clearly indicates the switch state.

- Operational with gloves: The lever design allows operation even when wearing thick gloves or in challenging conditions.

- Accessibility: The lever action can be easier for users with limited dexterity compared to other switch types.

- Multiple circuit configurations: Available in various pole and throw configurations for different circuit requirements.

- Voltage and current options: Manufactured for applications from low-voltage electronics to high-power industrial systems.

- Environmental adaptations: Available with waterproofing, dust protection, and temperature resistance for challenging environments.

- Customization options: Offered with different lever styles, colors, illumination, and mounting options to suit specific needs.

Classification by Style

- Flip-up covers that must be lifted before accessing the toggle

- Boot covers that allow operation while providing environmental protection

- Safety covers that require deliberate action to access the switch

- Control panels with space constraints

- Applications where protruding toggles could be damaged

- Aesthetic installations where a sleek appearance is desired

- Dark environments where switch status must be visible

- Complex control panels where quick status identification is important

- Applications where confirmation of power flow is necessary

- Automotive and aviation dashboards

- Marine applications

- Outdoor equipment

- Food processing machinery

- High-humidity environments

- Applications exposed to cleaning sprays or splashes

- Industrial machinery

- Construction equipment

- Military applications

- High-vibration environments

- Applications requiring extended operational life

- Function: Determine exactly what the switch needs to control and how it should operate.

- User interaction: Consider who will be operating the switch and under what conditions.

- Environmental conditions: Identify any challenging environmental factors the switch will face.

- Regulatory requirements: Check if there are industry standards or regulations that apply to the application.

- Voltage rating: Select a switch rated for at least the maximum voltage it will encounter.

- Current rating: Ensure the switch can handle the maximum current of the circuit, with an appropriate safety margin.

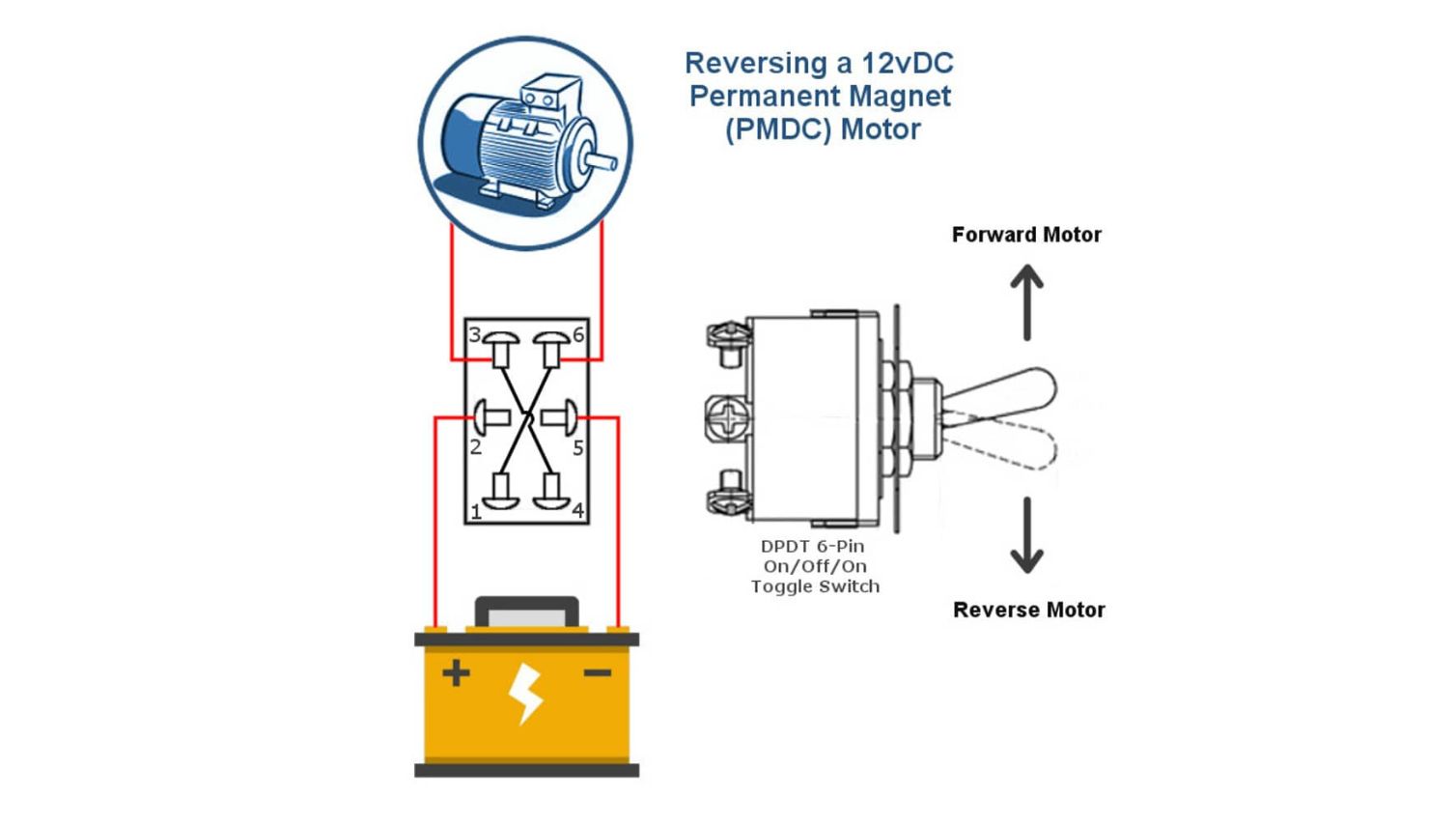

- AC vs. DC operation: Some switches are rated differently for AC and DC; verify the switch is suitable for your power type.

- Inductive loads: If switching motors or other inductive loads, select a switch with appropriate ratings for inductive applications.

- Contact material: For specialized applications, consider switches with contacts made from materials optimized for the specific voltage, current, and switching frequency.

- Temperature extremes: Select a switch rated for the full temperature range it will experience.

- Moisture exposure: For damp or wet environments, choose waterproof or sealed switches.

- Dust and contaminants: In dusty environments, sealed switches prevent ingress of particles.

- Vibration and shock: For applications with significant vibration, select switches designed to withstand mechanical stress.

- Chemical exposure: If the switch may be exposed to chemicals, ensure the housing material is compatible.

- Panel cutout dimensions: Ensure the switch will fit in the available mounting space.

- Mounting depth: Check that there is sufficient clearance behind the panel for the switch body and terminals.

- Terminal type: Select appropriate terminal types (solder, quick-connect, screw, PCB) for your application.

- Panel thickness: Verify that the switch mounting hardware is compatible with your panel thickness.

- Orientation: Consider whether the switch will be mounted horizontally, vertically, or at an angle.

- Frequent operation: For switches that will be used many times daily, select models with higher mechanical life ratings.

- Critical applications: In applications where failure could have serious consequences, choose switches with the highest reliability ratings.

- Expected service life: Match the switch’s rated operational life to the expected service life of the equipment.

- UL/CSA certification: For North American applications, look for Underwriters Laboratories or Canadian Standards Association approval.

- CE marking: For European applications, ensure compliance with relevant European directives.

- IP ratings: For environmental protection, check the Ingress Protection rating for dust and water resistance.

- Industry-specific standards: Some industries have additional requirements for switches used in their applications.

Related Product

Toggle Switches FAQs

Toggle Switches are commonly used in various applications, and people often have questions about them. Here are five of the most popular FAQs for Toggle Switches:

Toggle switches are typically made from durable materials like metal and high-quality plastic for the housing, with internal contacts made of conductive materials such as copper or silver. These materials ensure that the switches are robust, reliable, and capable of withstanding frequent use.

Yes, toggle switches can be used in both AC and DC circuits, provided they are rated for the appropriate voltage and current of the application. It is crucial to check the switch’s specifications to ensure it is suitable for the specific electrical requirements.

The advantages of using toggle switches include their simplicity, reliability, and ease of use. They are widely available in various configurations, making them versatile for different applications. Toggle switches are also durable and can handle high levels of current and voltage, depending on their design.

Yes, waterproof toggle switches are available and are especially useful in outdoor, marine, or industrial environments where the switch may be exposed to moisture, dust, or other harsh conditions. These switches are typically sealed with rubber or silicone to prevent water ingress and ensure long-term reliability.

Yes, many 12V toggle switches, including those from WEUP, are designed to withstand harsh environments. There are waterproof and dustproof models available that meet IP67 standards, making them suitable for use in marine, automotive, and industrial settings where exposure to water and dust is common.

Maintaining a toggle switch involves regularly inspecting it for signs of wear, ensuring it remains clean and free from dust and debris, and checking that the connections are secure. In environments exposed to moisture or dirt, it’s also important to ensure that any seals or gaskets remain intact to prevent damage.

A maintained toggle switch stays in the position it is toggled to until it is toggled back. For example, if you flip it to the “on” position, it stays on until you flip it to “off.” On the other hand, a momentary toggle switch only stays in the “on” position as long as you hold it down. Once you release it, it returns to the “off” position. This is ideal for functions that require a temporary connection, such as activating a horn or a starter motor.

Yes, in many cases, a toggle switch can be replaced with a rocker switch, provided the electrical ratings (voltage and current) and the type of operation (such as SPST or DPDT) are the same. However, you’ll need to ensure the replacement switch fits the existing mounting hole or panel cutout.

For high-current applications, it’s important to select a toggle switch that is rated for the specific current you need to control. Look for switches with a higher amperage rating, durable materials, and robust construction. Some high-current switches are also equipped with features like arc suppression to handle the increased electrical load.

The IP (Ingress Protection) rating indicates the level of protection a toggle switch has against dust and water. For example, an IP67 rating means the switch is completely dust-tight and can be submerged in water up to 1 meter deep for a specified time. This rating is particularly important for switches used in outdoor, marine, or industrial environments.