The dimensions of a power tool switch–its size and weight–are often overlooked, yet critical elements in determining its overall performance. This article delves into the dichotomy between the physical properties of these switches and their resultant functionality, specifically focusing on how size and weight influence performance.

The discussion expands on the technical aspects of power tool switches, elucidating the role that size plays in their operation, followed by an examination of how weight impacts usability. User experience is also given significant consideration as it provides valuable insights for optimizing switch performance.

Guidance for selecting appropriate power tools based on switch performance is provided, enriched with real-world case studies. The aim is to foster a deeper understanding of this topic among professionals involved in design, manufacturing or use of power tools with a view toward enhancing productivity and safety standards in work environments that utilize such equipment.

Introduction Power Tool Switch

The performance of power tool switches significantly influences the overall functionality and efficiency of these devices, underscoring its critical role in both professional and personal applications.

Various factors contribute to the performance level of these switches, among which the dimensions and weight are noteworthy.

A preliminary examination suggests that size and weight can profoundly impact switch performance, affecting parameters such as durability, ease of use, and reliability.

Importance of power tool switch performance

Optimal performance of power tool switches plays a critical role in ensuring efficiency and safety during operation, positioning it as an essential aspect to consider in the design and manufacturing process. The impact of switch size and weight can significantly influence factors such as Switch Durability, User Safety, Maintenance Requirements, and Power Consumption.

For instance, heavier switches may consume more power but offer longer durability because they often comprise robust Switch Materials. Conversely, lighter ones might require frequent Switch Replacement due to wear and tear but could potentially entail lower energy consumption.

| Factors | Lighter Switches | Heavier Switches |

|---|---|---|

| Switch Durability | Less Durable | More Durable |

| User Safety | Potentially safer | Depends on design |

| Maintenance Needs | High | Low |

| Power Consumption | Low | High |

| Switch Replacement | Frequent | Less frequent |

These considerations underline the importance of understanding the relationship between switch size, weight and performance characteristics for efficient tool usage.

The impact of size and weight on switch performance

Intricate interplays between dimensions and mass of a control mechanism can significantly influence its functional efficiency, durability, safety measures, maintenance requirements, and energy utilization in various mechanical devices.

Size and weight have substantial bearings on power tool switch performance. From a technological standpoint, smaller switches with reduced weights generally tend to overheat more quickly due to less heat dissipation capacity, potentially compromising switch durability.

Maintenance requirements often increase for heavy switches due to the additional strain on supporting components. Customization possibilities are also limited by size constraints as larger switches offer more flexibility for modifications.

User safety is another crucial consideration that is impacted by both size and weight factors along with environmental conditions. Thus, it becomes evident that these two physical characteristics play a pivotal role in shaping power tool switch performance.

Understanding Power Tool Switches

Power tool switches, essential components which regulate the flow of electricity to the device, serve a crucial function in tools’ operation and safety.

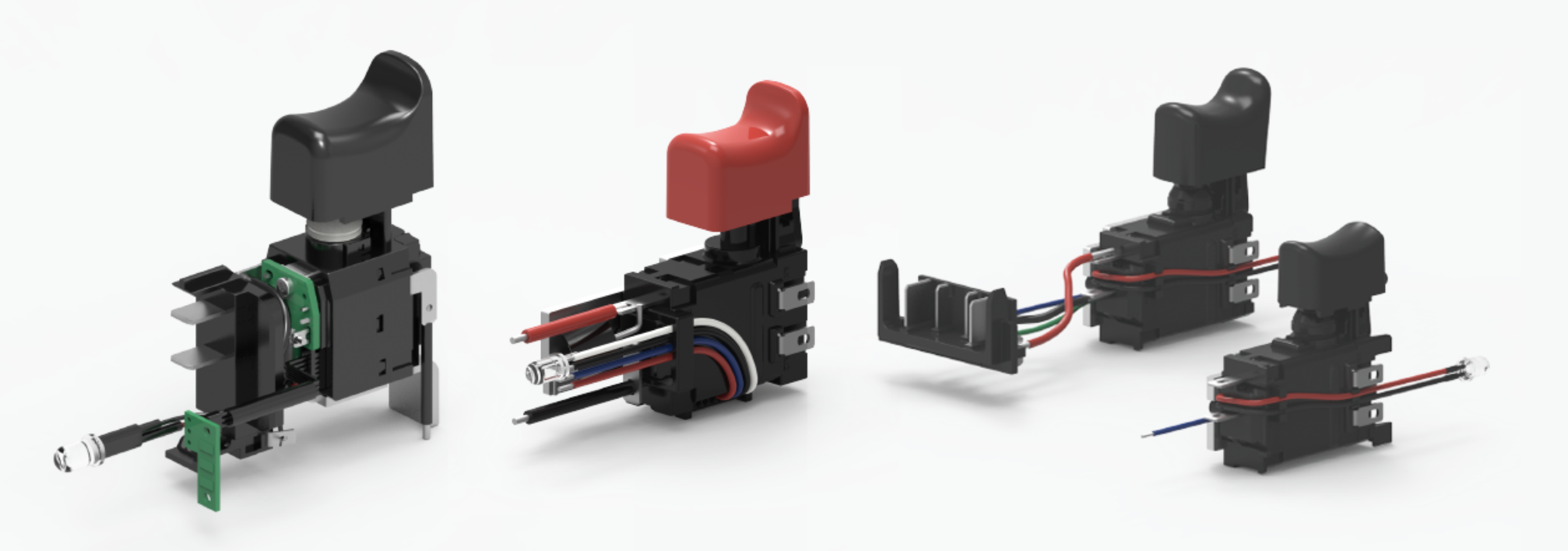

These switches come in various forms such as toggle, push button or trigger switches, each with their own unique characteristics and applications within different power tools.

It is therefore imperative to focus on switch quality and reliability, as these factors directly influence not only the longevity of the tool but also its operational efficiency and safety standards during use.

Definition, function and purpose of power tool switches

Undeniably, the switches of power tools form a critical part of their functionality, responsible for controlling the flow of electricity and enabling or ceasing the operation of these devices. The performance and reliability depend on various factors including switch durability, operator safety, weather resistance, voltage considerations, maintenance needs and material innovations.

| Factor | Description |

|---|---|

| Switch Durability | It refers to how well a switch can endure repeated use without failure. This is particularly crucial in power tools that undergo heavy duty applications |

| Operator Safety | Power tool switches play an essential role in ensuring user safety by providing firm control over the operation thereby reducing accidents |

| Weather Resistance | Quality switches are designed to withstand harsh environmental conditions like extreme temperatures and moisture |

| Voltage Considerations | Efficient switches are capable of handling high voltage levels without malfunctioning |

| Maintenance Needs | Switches with minimal maintenance requirements contribute towards overall tool longevity |

| Material Innovations | Advances in materials have led to more robust and durable switches capable of withstanding rigorous usage conditions |

Common types of power tool switches

Diving into the realm of hardware, it is crucial to understand the different types of common switches utilized in power tools, each synonymous with specific functionality and operational ease.

These Switch Types range from trigger switches used in drills and saws, offering immediate on/off control; toggle switches typically found in smaller handheld tools; to momentary contact switches utilized in professional tools due to their safety measures.

The choice of switch materials directly impacts durability and maintenance requirements. Plastic or rubber components are commonly preferred for their resistance to wear and corrosion, ensuring longevity even under harsh conditions.

Knowledge of these aspects influences tool selection based on use frequency, be it sporadic DIY Projects or regular professional usage requiring constant maintenance tips adherence.

Importance of switch quality and reliability

In evaluating the longevity and effectiveness of hardware equipment, the quality and reliability of their switches emerge as critical determinants. Noteworthy factors such as switch maintenance, user safety, product longevity, manufacturing costs, technological innovations, and environmental considerations play a substantial role in this.

An excellent switch ensures efficient tool operation with minimal maintenance requirements, thereby promoting user safety. This subsequently leads to improved product longevity, which is beneficial for both users and manufacturers in terms of reduced replacement or repair costs.

Simultaneously, contemporary technological innovations have facilitated the production of high-quality switches at lower manufacturing costs.

Finally, eco-friendly switch designs that minimize energy consumption are becoming increasingly prevalent due to growing environmental considerations within the power tool industry.

The Influence of Size on Switch Performance

Investigating the correlation between switch size and performance sets the foundation for a comprehensive understanding of power tool functioning (3.1).

Careful consideration of various factors, such as task requirements and tool specifications, is imperative when deciding upon an appropriate switch size for distinct power tools (3.2).

Additionally, the influence that switch size exerts on ergonomics and user experience cannot be overlooked, as it significantly affects comfortability and ease of operation during prolonged use (3.3).

Exploring the relationship between switch size and performance

Surprisingly, the size of the switch in power tools plays a significant role in its performance, with larger switches often facilitating better control and efficiency. This relationship between switch size and performance can be investigated from several perspectives:

- Switch Durability: Larger switches typically offer enhanced durability due to their robust construction.

- Ergonomic Design: A larger switch might result in improved ergonomics, leading to increased user safety and comfort during operation.

- Switch Materials: The size can influence the type of materials used for the switch, impacting its maintenance aspects.

- Innovative Technologies: With more space available, manufacturers can incorporate innovative technologies to enhance performance.

The ongoing advancements in technology may further influence how the size of a power tool’s switch affects its overall performance.

Factors to consider when selecting switch size for specific power tools

Selecting the appropriate dimensions for a control mechanism in machinery such as power tools necessitates careful consideration of several factors, including durability, ergonomics, material composition, and potential for technological enhancements.

Switch durability is critical to ensure the longevity of the tool and reduce frequent tool maintenance costs. User safety should be prioritized; hence switch size should facilitate ease of operation without compromising safety. Manufacturer responsibility encompasses providing clear instructions on usage and maintenance.

Innovative designs with enhanced materials can significantly improve performance while ensuring durability. Switch materials need to withstand harsh conditions but remain user-friendly.

The table below summarizes these points:

| Factor | Description | Impact |

|---|---|---|

| Switch Durability | Resilience under intensive use | Decreases maintenance costs |

| User Safety | Ease of operation & safety features | Prevents accidents |

| Manufacturer Responsibility | Clear usage & maintenance instructions | Ensures proper handling |

| Innovative Designs/Materials | Technologically advanced switches & durable materials | Improves performance & lifespan |

By considering these aspects, manufacturers can produce high-performing power tools with efficient switches.

Impact of size on ergonomics and user experience

Ergonomic considerations and user experience are significantly influenced by the proportions of control mechanisms in machinery such as power tools. The size of tool switches, particularly, has a substantial effect on switch ergonomics and overall tool handling.

- User comfort: A well-sized switch facilitates comfortable grip and eases operation, thus minimizing hand fatigue during prolonged use.

- Hand fatigue: Larger or smaller than necessary switches can induce unnecessary strain on the hands leading to accelerated fatigue.

- Safety considerations: Appropriately sized switches reduce the risk of accidental activation or deactivation, thereby enhancing safety.

- Design aesthetics: Lastly, switch size contributes to the overall look and feel of power tools which influence users’ perception and acceptance.

In essence, careful consideration should be given to switch sizes in power tools for optimal performance and user satisfaction.

The Role of Weight in Switch Performance

The examination of the impact of switch weight on power tool functionality serves as a critical facet in understanding overall performance. This exploration necessitates an evaluation of key considerations for striking an optimal balance between weight and performance, ensuring efficient operation without compromising on utility.

Further, it is incumbent to investigate the effect of weight on user fatigue and comfort, illustrating how these factors may influence prolonged use and efficiency during operation.

Examining the impact of switch weight on power tool functionality

In the realm of power tool design, it’s not a piece of cake to balance switch weight and functionality, as an increase in switch weight can potentially hamper the smooth operation of these devices.

The interplay between switch durability and material impact becomes pivotal; heavier switches might exhibit increased longevity but could compromise user comfort or impede switch accessibility.

Tool ergonomics also plays an essential role in this discourse, necessitating careful consideration when integrating weightier switches into power tool designs.

Thus, performance optimization is a complex juggling act involving various factors like durability, comfort, accessibility, ergonomics – all intertwined with the crux point being the weight of the switch.

Therefore, this intricate relationship demands meticulous attention for achieving optimal power tool functionality.

Considerations for balancing weight and performance

Striking a harmonious balance between durability and functionality necessitates careful thought and prudent design choices. Efficient tool performance is often compromised by increased weight, however, this does not diminish its importance in switch durability.

- Switch Durability: A heavier switch usually offers greater endurance against wear and tear, contributing to tool longevity.

- Tool Efficiency: Optimization of performance may require lighter switches for ease of operation yet maintaining efficiency.

- Switch Maintenance: Heavy switches might demand more frequent maintenance which could influence the overall efficiency of the power tool.

- Safety Measures: Regardless of weight, safety measures such as insulating materials should be incorporated to shield users from potential risks.

In conclusion, striking an equilibrium between weight and performance requires meticulous planning and consideration for user safety, tool efficiency, maintenance needs, and long-term durability.

Effect of weight on user fatigue and comfort

Transitioning from the discourse on balancing weight and performance, it becomes evident that weight can significantly impact user comfort and fatigue. The perception of a power tool’s weight is directly related to the user’s strength. Excessive weight can lead to fatigue, which impacts switch performance negatively during prolonged usage.

| Factors | Impact |

|---|---|

| Weight Perception | Influences how heavy a tool appears, impacting user’s handling ability. |

| User Strength | Determines capacity to handle heavier tools without excessive strain. |

| Fatigue Mitigation | Essential for extended usage as increased weight triggers faster exhaustion. |

| Comfort Optimization | Lighter tools improve comfort levels, aiding in better switch control. |

| Ergonomic Design | Helps distribute weight evenly, reducing strain and optimizing comfort |

Hence, an optimal balance between size, weight and ergonomic design is crucial for ensuring reduced fatigue and enhanced comfort during extended use of power tools.

User Experience and Feedback for Optimizing Switch Performance

The evaluation of switch performance in power tools necessitates a comprehensive investigation into user experience, which can be achieved via interviews with power tool users (5.1).

This method facilitates the identification of prevalent issues and complaints pertaining to switch size and weight, thereby providing invaluable insight into the real-world implications of these factors on device operation (5.2).

Furthermore, integrating such feedback mechanisms into product design and development processes presents an effective strategy for enhancing switch functionality in line with user needs and preferences (5.3).

Interviews with power tool users regarding switch performance

Insights gleaned from interviews with power tool users reveal a notable correlation between switch performance and the size and weight of the tools, despite initial skepticism about the potential impact of these physical attributes.

Findings indicate that:

- Switch maintenance: Larger, heavier tools often require more frequent servicing to maintain optimal switch functionality.

- User adaptability: Users must adapt their handling techniques for different sizes and weights to ensure efficient switch operation.

- Switch durability: A tool’s weight and size can influence the wear-and-tear on switches impacting their lifespan.

Furthermore:

- Tool lifespan: Proper management of switches in heavy-duty tools can prolong overall tool longevity.

- Safety measures: The right balance between size, weight and switch performance is vital for user safety.

These professional insights underscore the importance of considering a tool’s physical features when examining switch performance.

Reflecting on common problems and grievances reported, it becomes evident that dimensions and heft of switches often lead to a variety of issues, ranging from difficulty in operation to equipment malfunction.

Switch maintenance is heavily influenced by the size and weight of the switch, as these factors can impact accessibility and cleaning processes. The material impact also cannot be overlooked; heavier switches may cause greater wear and tear on internal components, affecting switch durability and escalating repair costs.

Furthermore, user adaptability is challenged when dealing with excessively large or heavy switches, leading to possible safety concerns due to improper usage or handling mishaps.

Thus, an appropriate balance in the size and weight of power tool switches is crucial for optimal performance and longevity.

Incorporating feedback mechanisms for improved switch functionality

Incorporation of feedback mechanisms can significantly enhance the functionality of electrical appliances, addressing user concerns and providing a more user-friendly experience.

For instance, in a hypothetical scenario, a drill manufacturer could integrate haptic feedback into their product’s switch mechanism to indicate successful activation, reducing uncertainty for the user and increasing overall safety during operation.

This design innovation not only adds to switch safety but also improves switch durability due to less erroneous usage.

Feedback implementation is a step towards ergonomic considerations that cater to user adaptability with varied hand sizes and weights.

The introduction of such advancements can revolutionize how power tools are perceived and used, thereby improving the overall operational efficiency while simultaneously mitigating common issues related to size and weight constraints on tool switches.

Manufacturer’s Perspective: Designing for Switch Performance

In the realm of power tool manufacturing, the design and performance of switches hold paramount importance. This significance emerges from a multitude of factors that influence decisions regarding size and weight during the production process.

The subsequent discussion will delve into these aspects, exploring how manufacturers prioritize switch design in power tools and identifying the elements that shape size and weight considerations.

How manufacturers prioritize switch design in power tools

Switch design in power tools is given significant attention by manufacturers due to its direct influence on tool performance and user experience. Manufacturers prioritize switch innovation, incorporating advanced technologies to enhance functionality while taking into account ergonomic considerations for user comfort.

Emphasizing user safety, they employ rigorous testing protocols to ensure that the switch can withstand intense usage without posing risk. Durability factors are also integral, with designs engineered for longevity even under strenuous conditions. Maintenance protocols are established, accommodating the potential need for switch replacement or repairs.

| Switch Design Priorities | Description |

|---|---|

| Advanced Technologies | Incorporate latest innovations to improve switch functionality |

| Ergonomic Considerations | Ensure comfortable usage of switches |

| User Safety | Implement rigorous testing to minimize risk |

| Durability Factors and Maintenance Protocols | Engineer switches for longevity and ease of maintenance |

This approach underscores the pivotal role of the switch in shaping tool performance and reliability.

Factors influencing size and weight decisions

Transitioning from the focus on how manufacturers prioritize switch design in power tools, it is necessary to delve deeper into the specific factors that influence decisions regarding size and weight.

- Switch Materials: The type and quality of materials used can directly affect both the size and weight of the power tool’s switch.

- Ergonomic Design: This concept plays a crucial role in determining the size and weight of switches, ensuring user comfort without compromising functionality.

- Switch Durability & User Safety: The balance between durability and user safety often affects decisions on switch dimensions, which must be robust enough to endure strenuous use while ensuring operator safety.

- Maintenance Tips & Innovative Technologies: Regular maintenance helps maintain optimal performance, whereas incorporating innovative technologies may lead to improvements in size, weight, durability, or ergonomics over time.

Choosing the Right Power Tool Based on Switch Performance

The position and accessibility of a switch in power tools are crucial factors that influence their ease of use and, consequently, performance (7.1).

Power tool manufacturers must thus consider various aspects during the design phase, such as switch placement, material selection for durability purposes, as well as user preferences and individual requirements (7.2 & 7.4).

These considerations also become pertinent when consumers select power tools, emphasizing the need to evaluate such factors to ensure optimal tool performance based on switch functionality (7.3 & 7.5).

Importance of switch placement and accessibility

Optimal positioning and easy accessibility of a power tool switch significantly influence user experience, efficiency, and safety during operation. The placement of the switch affects its durability, as it determines exposure to wear and tear during use.

User safety is also impacted by switch location; an easily accessible switch can prevent accidents by allowing for quick shut-down in emergencies.

Maintenance ease is another crucial consideration that depends on the access to the switch for cleaning or replacement purposes.

Weather resistance is directly linked to switch placement; switches exposed to harsh conditions may require more frequent replacements, impacting cost implications.

Therefore, careful attention must be invested in power tool design to ensure balance between functionally effective switch placement and efficient cost management strategies.

Key considerations for power tool manufacturers in switch design

Careful deliberation is necessary for manufacturers when designing the operational elements of machinery, with particular attention to critical aspects such as accessibility, durability, user safety, ease of maintenance and cost-effectiveness. Among these factors, switch materials play a crucial role in ensuring efficient performance, long-term functionality and weather resistance.

High-quality materials can contribute to user safety by reducing the risk of malfunction or failure during operation. However, this must be balanced against manufacturing costs and potential maintenance implications. Continuous research into future innovations can provide new opportunities for improving switch design while keeping costs manageable.

For instance, advances in material science could lead to more durable and reliable switches that require less frequent replacement or repair. The balance between these considerations will shape the future direction of power tool switch design.

Factors to consider when selecting power tools based on switch performance

Ironically, while choosing equipment based on operational elements may seem trivial to some, seasoned professionals understand that the efficiency of these components can significantly influence their workflow and productivity. When selecting power tools, considering switch performance is crucial for multiple reasons.

| Factors to Consider | Why it Matters |

|---|---|

| Switch Maintenance | Ensures power efficiency and user safety through regular inspection and repair |

| User Safety | Directly influenced by switch durability and innovative designs that prevent accidental activations |

| Switch Durability | Renders tool longevity; a robust switch withstands frequent use without significant wear or failure |

| Power Efficiency & Tool Longevity | Dependent on switch performance; efficient switches contribute to prolonged tool lifespan |

In conclusion, factors such as maintenance requirements, safety features, durability of the switch mechanism and power efficiency should be carefully considered during power tool selection.

Material selection for switches and their impact on durability

The choice of materials used in constructing switches significantly contributes to their durability, thus influencing the overall lifespan and functionality of power tools.

Several factors should be considered when selecting switch materials, including:

- Durability factors: The material must withstand frequent use without deteriorating.

- Extreme conditions: The material should perform optimally under various environmental conditions such as high temperature or humidity.

- Wear resistance: Materials with high wear resistance are preferred as they reduce the frequency of switch replacement.

- Material cost effectiveness: Although quality is paramount, the cost-effectiveness of a material cannot be ignored.

Innovative materials that encapsulate these attributes are continually being developed and incorporated into power tool switches to enhance performance and longevity while ensuring cost-effectiveness.

User preferences and individual needs

Understanding user preferences and individual needs is paramount in the design and development of power equipment, as these factors significantly influence customer satisfaction and product usability.

The implementation of customizable switches allows for an enhanced user experience by catering to specific requirements, while innovative designs aim at improving switch safety.

Switch maintenance is also essential, with replacement parts playing a crucial role in extending the lifespan of the tool and ensuring optimal performance.

Digital switches have emerged as a promising technology owing to their potential for increased precision and reliability. However, these modern adaptations must balance innovation with practicality to ensure they meet diverse user needs without compromising functionality or safety.

Consequently, understanding users’ preferences becomes integral to maximize the effectiveness of power tool switches.

Case Studies: Real-World Examples

Section 8 focuses on illuminating the concepts discussed previously through practical real-world examples.

These include Case Study 1, which examines the effect of size and weight on a cordless drill switch;

Case Study 2, which contrasts different switch sizes and weights in a circular saw;

and finally, Case Study 3 which evaluates switch performance in heavy-duty power tools.

By delving into these case studies, the intricate relationships between size, weight and switch performance in various power tools can be better understood and appreciated.

Case study 1: Impact of size and weight on a cordless drill switch

Analyzing a specific instance, the impact of size and weight on a cordless drill switch reveals intriguing relationships and trade-offs in their performance. Drill durability is directly affected by the switch’s size and weight; larger, heavier switches often denote sturdier construction using superior switch materials, enhancing longevity. However, this may necessitate additional user training to manage increased tool heft without compromising safety measures.

Conversely, smaller, lightweight switches can make handling easier but may require more frequent maintenance due to potential wear and tear.

Advanced technologies are instrumental in addressing these issues. For example, innovative designs are emerging that optimize size and weight without sacrificing durability or safety. This indicates the importance of continuous research into power tool switch performance to realize better tools for users worldwide.

Case study 2: Comparison of different switch sizes and weights in a circular saw

A comprehensive comparison of various dimensions and masses in circular saw switches, akin to the old saying ‘comparing apples to oranges’, reveals striking disparities that can significantly influence their durability, user comfort, and maintenance needs.

Larger switches often boast enhanced switch durability due to increased material resilience but may pose challenges for specific user demographics, particularly those with smaller hands.

Conversely, lighter-weight switches could improve user comfort but potentially compromise on longevity. Safety measures must be meticulously considered across all sizes and weights to prevent mishaps during industrial applications.

Moreover, larger or weightier switches might necessitate more frequent maintenance routines due to the higher strain endured from prolonged usage.

Consequently, manufacturers must strike a balance between these factors when designing power tool switches for varied demographic profiles and application requirements.

Case study 3: Evaluation of switch performance in heavy-duty power tools

In this case study, the efficacy of various control mechanisms in robust machinery is thoroughly evaluated, underscoring the necessity for manufacturers to achieve an optimal balance between user-friendliness, longevity and safety. Special attention was paid to switch durability, material selection, and user comfort as key variables influencing tool longevity and performance optimization.

The below table presents a summary of the findings:

| Criteria | Impact on Performance | Suggestions for Improvement |

|---|---|---|

| Switch Durability | Directly affects tool life span & efficient operation | Use high-strength resilient materials |

| Material Selection | Influences switch responsiveness & maintenance frequency | Opt for materials reducing wear and tear |

| User Comfort | Impacts extended use without fatigue or discomfort | Design ergonomically shaped switches |

Considering these factors during manufacturing can lead to enhanced switch performance with minimized need for constant switch maintenance.

Frequently Asked Questions (FAQs)

How does the size of a power tool switch affect its performance?

Size significantly influences the performance of a power tool switch, as larger switches may offer more durability and longevity but could potentially limit the tool’s overall maneuverability and ease of use. Switch durability is often enhanced in larger designs due to their ability to withstand higher levels of mechanical stress, directly contributing to tool longevity.

However, safety considerations must be taken into account as larger switches can be more challenging to operate swiftly in emergency situations. The choice of switch material also plays a crucial role in its size and weight impact on performance, with heavier materials generally offering greater resistance to wear but requiring increased maintenance needs.

Lastly, the ergonomics of the tool can be affected negatively by an oversized switch, possibly leading to reduced user comfort over extended periods of usage.

What is the ideal weight for a power tool switch?

Striking a balance between durability and user comfort, the optimal heft of a control mechanism for mechanical devices remains a topic of ongoing examination.

The ideal weight for a power tool switch can influence not only its durability but also user safety. Lightweight switches may offer ease of use, but their durability can be compromised due to the less robust materials used in their fabrication. Conversely, heavier switches tend to have superior switch durability but may strain the user over prolonged periods.

Technological advancements have made it possible to optimize this balance further by offering customization options that cater to individual preferences.

Meanwhile, maintenance tips suggest regular inspection and cleaning to prolong switch lifespan.

Finally, environmental impact considerations are driving efforts towards sustainable manufacturing processes and materials in power tool switch design.

Can a heavy switch negatively impact power tool functionality?

Following an in-depth analysis of the ideal weight of a power tool switch, it is essential to delve into whether a heavy switch can negatively impact the tool’s performance.

Switch durability is indeed influenced by size and weight. Excessive heaviness could lead to wear and tear, reducing the lifespan of the switch. Material choices also play a significant role as heavier materials might adversely affect operational efficiency.

Moreover, industry regulations necessitate maintaining certain standards that ensure user safety and functionality. Advancements in design innovations continually strive to balance weight, durability, and efficiency of switches.

Lastly, maintenance tips often advise regular checks for signs of strain caused by disproportionate weight or size, reinforcing the crucial role these factors play in preserving optimal power tool performance.

Are there any industry standards for power tool switch size and weight?

In the realm of manufacturing and design, there are indeed established guidelines that dictate the parameters for components like switches in power tools. These guidelines encompass switch regulations, ergonomic considerations, durability factors, maintenance tips, technological advancements, and user safety.

Switch regulations stipulate dimensions and weight requirements to ensure consistent performance across varying tool models.

Ergonomic considerations involve designing switches for ease of use without causing strain or discomfort to users.

Durability factors necessitate that switches can withstand prolonged usage under diverse conditions.

Maintenance tips are provided so that even with wear and tear, optimum performance is sustained.

Technological advancements have led to improvements in switch design ensuring longevity and efficiency.

Lastly, user safety provisions demand safeguards against accidental activation or deactivation of power tools during operation.

How can users improve switch performance in their power tools?

Ensuring the longevity and optimal functionality of a power tool’s control mechanism can be achieved by adhering to specific maintenance practices that may seem as boundless as the ocean in their scope.

Switch maintenance plays a crucial role in this endeavor, with performance testing serving as an integral part of preventative measures.

User training on proper handling and care of tools could significantly contribute to tool longevity, reducing mechanical failures and increasing safety measures.

Innovative designs often incorporate features that improve switch performance, making it easier for users to maintain their tools effectively.

These strategies not only enhance the switch performance but also ensure safe usage, thereby positively impacting overall productivity and work efficiency in various construction or DIY projects.

Conclusion

The impact of size and weight on power tool switch performance

Analyzing the correlation between size and weight of power tool switches underscores their consequential role in overall performance. A significant relationship exists between these factors as they directly impact switch longevity, with larger and heavier switches often showcasing greater durability. However, maintenance tips are essential to ensure their optimal function, including regular cleaning and potential switch modifications for improved performance.

Switch safety is another crucial aspect influenced by size and weight; lighter switches may reduce user fatigue but could compromise stability. Eco-friendly switches, typically smaller and lighter, promote sustainable practices without sacrificing functionality.

Lastly, ongoing innovations continue to revolutionize power tool switches design parameters concerning size and weight, thereby enhancing their efficiency and effectiveness while maintaining user safety standards.

Final thoughts on the importance of considering switch design in power tool selection

Reflecting on the critical role of switch design in the selection process of power equipment, it is apparent that careful consideration can significantly enhance operational efficiency, user safety, and overall tool longevity. A well-designed switch not only affects its longevity but also impacts the environmental footprint through reduced need for switch maintenance.

The following table further illustrates these considerations:

| Consideration | Impact |

|---|---|

| Switch Longevity | Leads to increased lifespan of power tools, reducing frequency of replacement |

| User Safety | Proper switch design can prevent accidental activation or deactivation |

| Switch Maintenance | Well-constructed switches require less frequent repairs |

| Environmental Impact | Durable switches result in less waste generation and resource consumption |

| Cost Effectiveness & Switch Innovation | Advances in technology introduce cost-effective solutions without compromising quality |

Thus, careful analysis should precede any decisions regarding power tool purchase.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd