As an orchestra conductor choreographs the symphony of instruments to create a harmonious melody, so does the Internet of Things (IoT) orchestrate the synchronization and communication of devices. The influence of IoT has permeated various sectors, including the power tool industry, where it has significantly revolutionized traditional power tool switches.

This article explores this transformative journey from conventional switches to smart IoT-powered switches in the realm of power tools. It further delves into how remote control capabilities have enhanced functionality, while real-time monitoring systems have improved safety parameters. However, as with any technological evolution, challenges persist alongside advancements – a facet that this discourse also addresses.

Moreover, real-life instances elucidating successful implementations will be highlighted for better comprehension. This investigation aims to provide a comprehensive understanding regarding the impact and potential implications of IoT on future power tool switches.

Introduction Power Tool Switches

The Internet of Things (IoT) represents a transformative paradigm shift in the realm of technology, characterized by interconnectivity and intelligence, which is reshaping various industries through seamless integration and automation.

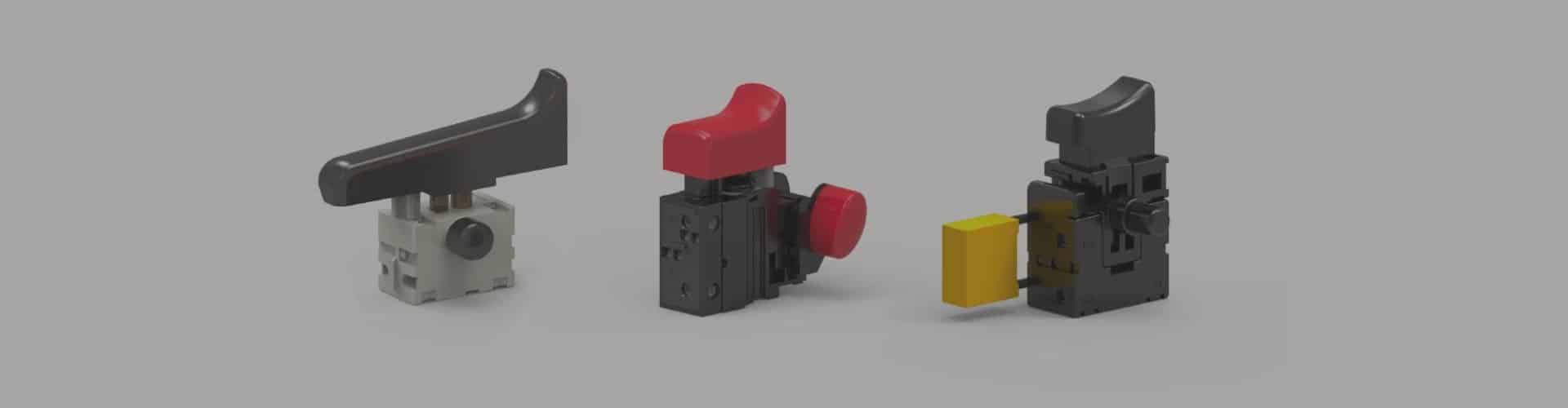

Power tool switches, pivotal components that ensure safety and control in power tools operations, are not exempt from this sweeping technological evolution.

The impending convergence of these two elements – IoT and power tool switches – promises to redefine operational efficiency, safety protocols, and user experience in the future.

Brief explanation of the concept of IoT and its role in transforming industries.

Internet of Things (IoT), a concept that revolves around connecting physical devices with the internet to collect and share data, has become instrumental in transforming industries by optimizing operations, improving decision-making, and creating new business models. IoT technology harnesses wireless technology to link smart devices, enabling real-time monitoring and predictive maintenance.

The table below presents some key ways IoT is transforming various sectors:

| Sector | Impact of IoT |

|---|---|

| Manufacturing | Improving operational efficiency through real-time tracking and predictive maintenance |

| Healthcare | Enhancing patient care through remote monitoring and telemedicine |

| Power Tools | Enhancing safety measures and performance optimization via smart switches |

| Retail | Personalizing customer experiences through targeted marketing |

| Transportation | Optimizing fleet management and fuel consumption |

Thus, the adoption of IoT applications is proving crucial in evolving industries for a technologically advanced future.

Introduction to power tool switches and their importance in ensuring safety and control.

In terms of ensuring safety and optimal control, understanding the pivotal role of switch mechanisms within power tools becomes indispensable. Power tool switches are manufactured by numerous firms, such as weup power tool switches manufacturer, to ensure user safety and device control. These switches play a critical function in regulating the operation of these tools, leading to improved efficiency and reduced risk of accidents.

Recognizing this importance, many manufacturers have invested heavily in their production lines to deliver top-notch products that meet consumers’ expectations. Indeed, any power tool switches factory or supplier can attest to the rising demand for reliable and efficient controls in the industry.

Thus, an introduction to power tool switches and their significance in ensuring safety and control is essential for every power tool switches vendor or potential consumer.

Traditional Power Tool Switches

Traditional power tool switches operate on a simple mechanism that enables the user to control the operation of the tool; this typically involves an electrical circuit being completed when the switch is turned on, thus powering the device.

Despite their wide application and ease of use, traditional switches are not without limitations, presenting several drawbacks that can hinder optimal performance. These challenges encompass issues such as susceptibility to wear and tear, limited lifespan due to mechanical components’ usage, slow response times in some instances, and lack of integration capabilities with advanced technologies like IoT.

How conventional power tool switches work.

Conventional power tool switches function by forming an electrical connection that allows the flow of current, thus enabling the device to operate. The switch’s design often depends on the type of power tool and its application.

Many power tool switches China manufacturers and suppliers use this conventional method due to its simplicity and efficiency. However, these switches can pose challenges in terms of energy efficiency and maintenance cost.

| Power Tool Switches Manufacturer | Concerns |

|---|---|

| Power Tool Switches China Manufacturer | Energy Efficiency |

| Power Tool Switches China Factory | Maintenance Cost |

| Power Tool Switches China Supplier/ Vendor | Improvements Needed |

The table indicates concerns associated with different types of providers. It underlines the need for technological advancements in this area, such as IoT integration, to overcome these issues.

Limitations and drawbacks associated with traditional switches.

Despite their widespread usage and apparent simplicity, conventional switches harbor a litany of limitations that hinder optimal performance and drive up costs—an ironic twist for devices intended to control power flow efficiently.

- The inability of traditional switches to provide real-time data on energy consumption poses a significant challenge in monitoring and managing power use effectively.

- Conventional devices lack the capacity for smart sensor integration, thereby limiting automation possibilities.

- Traditional switches do not facilitate wireless sensor network connectivity, restricting remote accessibility and control.

- Unlike IoT-enabled switches, conventional counterparts don’t offer cost-saving benefits derived from predictive maintenance strategies.

- The absence of sophisticated energy management capacities in traditional switches inevitably leads to inefficient utilization of electricity.

These shortcomings underscore the pressing need for an innovative approach towards power tool switch design—an avenue where IoT stands poised to make a significant impact.

The Emergence of Smart Power Tool Switches

The evolution of power tool switches has been significantly shaped by the advent of Internet of Things (IoT) technology, giving rise to what is now known as smart power tool switches.

These innovative devices come equipped with a plethora of advanced features that redefine the user experience, most notably, remote control capabilities, real-time monitoring, and data analytics.

The ensuing discussion will offer an in-depth exploration into how these features contribute to enhanced operational efficiency and safety in various industrial applications.

Introduction to smart power tool switches enabled by IoT technology.

Harnessing the potential of Internet of Things (IoT) technology, smart power tool switches are set to revolutionize the industry with their enhanced efficiency and real-time data capabilities. These switches, an integral element in the realm of interconnected devices, are considered smart objects that can communicate with each other through IoT technology.

The first application of these switches is cost reduction. By utilizing sensor-driven decision-making processes, energy usage can be optimized leading to significant reductions in operational costs.

Smart power tool switches also have the potential to prevent damage or misuse by monitoring usage patterns and providing real-time feedback.

Lastly, they enable seamless integration with other smart objects within a networked environment, enhancing overall system functionality.

In conclusion, IoT-enabled smart power tool switches present promising prospects for advancing industrial operations.

Key features offered by these devices, such as remote control capabilities, real-time monitoring, and data analytics.

Innovations in smart device technology have paved the way for a host of remarkable features, such as remote control capabilities, real-time monitoring, and data analytics. These technologies have the potential to significantly impact the future of power tool switches.

The integration of IoT enables power tools with remote control capabilities that enhance user convenience and operational efficiency. This could range from simple on/off functionalities to speed adjustments or mode switching.

Additionally, through real-time monitoring facilitated by IoT devices, users can track usage patterns and detect malfunctions early.

Data analytics further enhances this feature by offering insights into energy consumption trends or predicting maintenance needs based on historical data.

Thus, the evolution of these technologies is poised to redefine traditional power tool switch operations profoundly.

Enhanced Functionality through Remote Control Capabilities

The advent of Internet of Things (IoT) technology has opened up a plethora of possibilities for power tool switches, particularly in terms of remote control capabilities. By leveraging smart devices such as smartphones, these IoT-enabled switches can be operated from afar, extending their utility beyond physical constraints.

This holds significant advantages for professionals who can now operate tools from a safe distance and control multiple tools simultaneously, demonstrating the transformative potential of this integration.

How IoT-enabled power tool switches can be controlled remotely using smartphones or other smart devices.

Embracing the advent of IoT-enabled power tool switches, it is foreseeable that these tools can be managed remotely using smartphones or other smart devices, opening up a world of unprecedented convenience and efficiency in the realm of construction and DIY projects. This results in substantial energy savings due to precise monitoring, enabled by connected devices.

Through digital technologies such as remote monitoring, oversight over power consumption becomes a seamless task with minimal human intervention. In essence, IoT facilitates better control and management resulting in optimized energy consumption.

Table: Potential Impacts of IoT on Power Tool Switches

| Energy Savings | Monitoring | Convenience | |

|---|---|---|---|

| Impact 1 | Enhanced control over energy usage | Real-time data access | Remote management |

| Impact 2 | Optimized energy use via automation | Predictive analysis capability | Reduced human intervention |

| Impact 3 | Lower operational costs | Improved system reliability | Effortless switch operation |

Advantages for professionals who can operate tools from a safe distance or control multiple tools simultaneously.

Professionals stand to gain significantly from advancements that allow for remote operation of tools, enhancing safety by enabling a safe distance between the worker and potentially hazardous operations. This capability reduces direct human interaction with potentially dangerous equipment while maintaining high operational standards.

Furthermore, the integration of IoT in physical devices can be achieved via multicore processors in power tool switches, facilitating real-time monitoring and efficient control at the application layer. This technological advancement enhances availability, allowing professionals to manage human activity more effectively during complex tasks.

In addition, the simultaneous control of multiple devices is made possible, increasing efficiency. The future of power tool switches reflects a safer and more efficient work environment due to IoT-enabled functionalities.

Real-Time Monitoring for Improved Safety

The advent of IoT-enabled power tool switches has led to a substantial improvement in safety measures, particularly through the integration of real-time monitoring features.

These advanced switches are equipped with sensor technologies that can identify potential risks such as overheating or abnormal vibrations, thus providing essential data for preventive action.

Consequently, this timely information allows operators to take necessary prevention measures based on real-time data, thereby substantially reducing the likelihood of accidents and enhancing overall safety during operations.

The benefits of real-time monitoring features provided by IoT-enabled power tool switches.

Real-time monitoring features inherent in IoT-enabled power tool switches offer significant benefits, including enhanced safety measures, increased efficiency, and proactive maintenance strategies. The impact of IoT on the future of power tool switches is evident when highlighting these advantages:

- Enhanced Safety: IoT-enabled switches can detect potential hazards and notify users in real-time, minimizing accidents.

- Increased Efficiency: Real-time monitoring features allow for optimal usage of tools, reducing energy waste.

- Proactive Maintenance: Predictive analytics provided by IoT devices can predict equipment failure before it happens.

- User-Friendly Interface: Easy-to-use digital platforms make operating tools more intuitive.

- Customized Experience: With smart technology, users can customize settings according to their needs.

These benefits underscore the transformative potential associated with the integration of IoT into power tool switches.

How sensors can detect anomalies such as overheating or abnormal vibrations.

Much like a watchful sentinel, embedded sensors in modern industrial equipment can vigilantly detect anomalies such as overheating or abnormal vibrations, thereby mitigating risks and preventing potential device failures. These sensors transform physical objects like power tools into smart devices that can autonomously monitor their performance.

As part of the Internet of Things (IoT) ecosystem, these sensors are akin to those found in wearable devices and mobile devices used extensively in healthcare. The processor within IoT-enabled power tool switches interprets the data from these sensors to recognize potential issues before they escalate into serious problems.

This predictive capability not only enhances safety but also contributes towards reducing the environmental impact by optimizing machine operation and minimizing waste production. Thus, sensor-embedded power tools signify a significant advancement in industry practices.

Prevention measures that can be taken based on real-time data to avoid accidents.

Transitioning from the examination of sensor detection mechanisms, it is essential to spotlight how real-time data provided by IoT can facilitate prevention measures to mitigate accidents.

The future of power tool switches will undoubtedly be influenced by these advancements. Real-time data enables immediate response to irregularities, aligning with the dynamic requirements of applications.

For instance, if a sensor in a saw detects overheating or unusual vibrations, IoT technology can automatically shut off the device or alert the user, thus preventing potential mishaps.

This approach is not limited to power tools but extends across industries including healthcare where patient monitoring systems use real-time data for early disease detection and treatment.

Henceforth, IoT’s role in predicting and preventing hazards underscores its transformative impact on future equipment safety standards.

Advanced Data Analytics for Efficiency Optimization

The exploration of Internet of Things (IoT) technology in the collection and analysis of data from power tool switches presents a promising frontier for efficiency optimization.

Emphasizing the benefits derived from these data-driven insights, such as enhanced tool performance, energy usage reduction, and predictive maintenance, underscores the significant potential that this technological integration holds.

Evidence from various instances where IoT-enabled power tool switches have successfully identified patterns and suggested improvements further substantiates this potential, paving the way for more innovative applications in this arena.

How IoT technology collects and analyzes data from power tool switches.

Harnessing the capabilities of IoT technology allows for real-time data collection and insightful analysis from power tool switches, driving efficiency and innovation in this sector.

The technique employed covers a wide range of aspects including object detection, temperature control, pressure monitoring, and more. This increases computational complexity owing to the huge amounts of data processed simultaneously.

The potential application of IoT extends beyond mere data collection; it offers predictive insights that can revolutionize safety measures and operational efficiency.

Traditional single-core processors may struggle with this high volume of complex information. However, advancements in multi-core processing technologies are making it possible to handle such complexities more efficiently.

Thus, IoT is shaping the future landscape of power tool switches by ensuring optimal performance through efficient data management strategies.

Benefits of data-driven insights in optimizing tool performance, energy usage, and predictive maintenance.

Ironically, in a world obsessed with innovation and newness, it is the seemingly mundane data from our everyday tools that holds the key to extraordinary leaps in performance optimization, energy efficiency, and predictive maintenance.

The range of data-driven insights available from IoT enabled power tool switches promises significant improvements across these dimensions. For instance, by continuously monitoring tool usage patterns and adjusting operations accordingly, IoT technology reduces energy consumption and enables considerable energy savings. This is a compelling advantage over generic IoT applications which often involve high initial cost but offer relatively low returns.

In contrast, integrating IoT into power tool switches comes at a comparably low initial cost while offering substantial long-term benefits including enhanced performance and proactive maintenance schedules.

How IoT-enabled power tool switches can identify patterns and suggest improvements.

Utilizing data-driven insights from connected devices, businesses can identify usage patterns in their machinery and subsequently propose enhancements to optimize performance. This is particularly relevant in the context of IoT-enabled power tool switches. These advanced devices not only provide real-time monitoring but also facilitate pattern recognition that could lead to significant improvements.

For instance, IoT technology can detect irregularities in the operation of power tool switches and suggest preventive measures to avoid future malfunctions. Moreover, by analyzing long-term usage data, IoT systems can predict optimal maintenance schedules, thereby prolonging the lifespan of these tools.

The impact of IoT on the future of power tool switches is thus multi-faceted- enhancing reliability, predicting maintenance needs, and enabling a more sustainable approach toward resource management in industries.

Connectivity and Integration with Other Smart Devices

The issue of compatibility and integration of IoT-enabled power tool switches with other smart devices within the workshop or construction site environment is a crucial aspect in the advancement of this technology.

The potential for these tools to be embedded within larger smart home or industrial automation systems broadens their utility and efficiency.

A comprehensive study on these aspects will provide valuable insights into how such integrations can revolutionize not only tool usage but also overall operational workflows across various industries.

The compatibility of IoT-enabled power tool switches with other smart devices in the workshop or construction site.

Imagine a bustling construction site where IoT-enabled power tool switches seamlessly interface with other smart devices, paving the way for unprecedented levels of efficiency and safety.

The impact of IoT on the future of power tool switches is manifested in their enhanced compatibility with other intelligent systems within the workspace. This synchronization allows for real-time monitoring and control, thus significantly reducing potential hazards associated with manual operation.

Furthermore, this integration fosters an environment where data from various smart devices can be pooled for advanced analytics leading to improved decision-making and operational performance.

Therefore, it is undeniable that the advent of IoT-enabled power tool switches will revolutionize the dynamics at both workshops and construction sites by offering superior connectivity options with other smart devices.

How power tools can be integrated into broader smart home or industrial automation systems.

Integration of power tools into broader smart home or industrial automation systems can significantly streamline operations and boost productivity by enabling seamless communication with other interconnected devices. This integration is made possible through IoT-enabled power tool switches that are designed to be part of a networked ecosystem.

- Interconnectivity: IoT allows power tools to communicate seamlessly with other smart devices in the system, facilitating efficient task management.

- Remote Management: With the help of internet connectivity, users can remotely control and monitor their power tools.

- Predictive Maintenance: By collecting data from integrated power tool switches, these systems can predict when a device might need maintenance, thus reducing downtime.

- Safety Enhancement: The future of smart homes and industrial automation systems lie in enhanced safety measures; IoT-enabled power tools contribute towards this by providing real-time alerts on operational hazards.

Challenges and Considerations for IoT Power Tool Switches

Acknowledging the potential challenges associated with IoT power tool switches is crucial to their effective implementation and management.

This includes mitigating cybersecurity risks, addressing data privacy concerns, and resolving interoperability issues that might arise.

Furthermore, the selection of credible manufacturers who prioritize security measures forms an essential part of this process, ensuring safe and secure operational capabilities.

Potential challenges such as cybersecurity risks, data privacy concerns, and interoperability issues.

Despite the potential benefits of IoT in power tool switches, it is imperative to consider and mitigate challenges such as cybersecurity risks, data privacy concerns, and interoperability issues to ensure a seamless and secure integration.

- Cybersecurity Risks: IoT devices are vulnerable to hacks that can disrupt their operation. For the future of power tool switches, manufacturers need robust security protocols to protect these tools from cyber threats.

- Data Privacy Concerns: As IoT-enabled power tools collect user data for improved performance monitoring, privacy issues arise. Measures should be implemented to keep this sensitive information confidential.

- Interoperability Issues: With various manufacturers producing IoT devices, compatibility problems may occur. Standards must be developed for seamless interaction among different IoT devices in future power tool switches.

Addressing these potential challenges ensures the benefits of incorporating IoT are fully realized while minimizing risks and concerns.

Importance of choosing reliable manufacturers who prioritize security measures.

Transitioning from the exploration of potential challenges such as cybersecurity risks, data privacy concerns, and interoperability issues associated with the integration of IoT in the future of power tool switches, attention must be directed towards another crucial aspect.

This encompasses the importance of choosing reliable manufacturers who prioritize security measures. It is imperative to note that the IoT infrastructure’s safety largely depends on its initial design and manufacturing process. Reliable manufacturers who place a high emphasis on implementing robust security measures play an essential role in mitigating risks related to cyber threats.

By doing so, they ensure enhanced protection for sensitive user data while also increasing device functionality. Therefore, selecting manufacturers committed to these principles is paramount in securing the future of power tool switches integrated with IoT technology.

Case Studies: Successful Implementations of IoT Power Tool Switches

Exploring real-world cases can elucidate the transformative potential of IoT-enabled power tool switches.

Numerous instances illustrate how this technology has spurred substantial improvements in productivity, safety, and efficiency within various industries.

The ensuing discourse will delve into these successful implementations, illuminating the tangible benefits yielded by the convergence of power tools and Internet of Things technology.

Real-life examples where IoT-enabled power tool switches have made a significant impact on productivity, safety, and efficiency.

In the dynamic world of construction, IoT-enabled power tool switches have revolutionized operations by significantly enhancing productivity, safety, and efficiency, instilling a sense of awe at the transformative potential of technology.

The integration of Internet of Things (IoT) in these tools has directly led to an upsurge in productivity levels. This is primarily because IoT-enabled power tool switches allow for real-time monitoring and control over equipment usage, thus reducing downtime and facilitating swift response to any technical issues.

Furthermore, the impact of IoT on safety measures is profound as it enables predictive maintenance thereby preventing accidents caused by equipment failure.

Lastly, efficiency is significantly boosted with streamlined operations enabled by IoT technologies. These advancements suggest a promising future for power tool switches influenced by IoT capabilities.

Frequently Asked Questions (FAQs):

The ensuing discourse seeks to elucidate on a range of frequently asked questions (FAQs) regarding the integration of Internet of Things (IoT) technology in power tool switches.

Central points include:

- An explanation of IoT

- Its role in enhancing power tool switches

- Benefits derived from using IoT-powered power tool switches

Attention is also devoted to understanding potential security risks associated with implementing IoT in power tools and the feasibility of retrofitting existing power tools with IoT-enabled switches.

What is the Internet of Things (IoT)?

Distinctly characterized by interconnectedness, the Internet of Things (IoT) refers to the vast network of physical devices embedded with software and sensors that facilitate data collection, sharing and analysis. Underpinning this article’s exploration of IoT’s impact on power tool switches in the future, it is essential to understand how these technologies interact.

The IoT allows for seamless integration between various components, enabling enhanced functionality and efficiency. This integration is particularly valuable within the context of power tool switches where data can be harnessed to improve safety measures, streamline operations, or provide real-time diagnostics.

Consequently, as this technology continues to evolve and become more ubiquitous, its influence over various aspects including power tool switches will undoubtedly shape their future trajectory.

How does IoT integration enhance power tool switches?

Harnessing the capabilities of interconnected technologies, it becomes possible to significantly enhance the functionality and efficiency of commonly utilized equipment such as drill or saw controllers. IoT integration has been identified as a key driver in advancing power tool switches.

The impact of IoT on these devices is remarkable, offering improved control, seamless operation, and enhanced safety measures. Through IoT-enabled switches, power tools can be remotely controlled, potentially reducing accident risks while increasing productivity.

Moreover, data collected via these smart switches can inform preventive maintenance schedules and improve lifespan predictions. According to an article published in IEEE Access, the future of power tool switches will see more advanced applications due to IoT innovations; thus underlining the transformative potential of this technology within this sector.

What are the benefits of using IoT-powered power tool switches?

Adapting interconnected technologies to control devices such as drills or saws brings a host of advantages, including enhanced operational efficiency, increased safety measures, and extended equipment lifespan.

IoT-powered power tool switches enable the utilization of electromagnetic energy sources to increase efficiency and minimize waste. Advanced energy harvesting techniques can be applied to sustain these systems in ultralow power applications, thereby prolonging their durability. The availability of heat sources within the working environment can also be exploited for energy generation.

Furthermore, an intriguing correlation between medical devices and IoT-enhanced tools is observed. Both heavily rely on wireless communication protocols and stringent safety standards outlined in the IEEE Commun Mag. Hence, the experience obtained from designing secure and efficient medical devices could benefit future IoT implementations in power tools.

Are there any security risks associated with implementing IoT in power tools?

Despite the numerous advantages associated with integrating advanced technologies into industrial equipment, it is crucial to consider potential security vulnerabilities that can emerge as a consequence of such implementations. It is particularly essential when considering the implementation of IoT in power tool switches.

- Unauthorized Access: The integration of IoT can potentially provide cybercriminals with an entry point into the network, leading to unauthorized access and control over power tools.

- Data Privacy Concerns: IoT devices often collect, transmit, and store user information raising issues related to data privacy if not properly secured.

- Firmware Updates: Outdated firmware could leave power tools vulnerable to attacks, thus requiring regular updates which may be overlooked or neglected by users due to unawareness or lackadaisical attitudes towards security measures.

Can existing power tools be retrofitted with IoT-enabled switches?

The potential for retrofitting existing industrial equipment with advanced, internet-enabled functionality presents an intriguing avenue for modernization and efficiency enhancement. Power tools are no exception to this trend, as their mechanical switches can be replaced with Internet of Things (IoT)-enabled counterparts. Such advancements not only usher in improved operational control and efficiency but also facilitate predictive maintenance, minimizing downtime.

| Advantages of Retrofitting | Disadvantages of Retrofitting |

|---|---|

| Enhanced Operational Control | Requires Skills & Knowledge |

| Improved Efficiency | Potential Security Risks |

| Predictive Maintenance | Increased Costs |

However, it is vital to take into account the necessary skills and knowledge required for such retrofitting undertakings. Moreover, increased costs and potential security risks associated with IoT implementation should not be overlooked while considering this transformation.

What industries can benefit from the adoption of IoT in power tool switches?

The discussion on retrofitting existing power tools with IoT-enabled switches brings to attention the significance of its mass adoption. A key aspect of this is identifying industries that stand to gain from incorporating IoT in their power tool switches.

- Construction Industry: Enhanced safety measures, predictive maintenance, and improved efficiency are potential benefits.

- Manufacturing Sector: Real-time data collection can streamline production processes and reduce downtime.

- Automotive Industry: Precision and consistency in production lines could be achieved.

- Energy Industry: IoT can ensure efficient usage of power tools, saving energy.

- Agriculture Sector: Smart farming equipment could make operations more efficient.

Thus, the integration of IoT into power tool switches harbors tremendous potential across various sectors by enhancing productivity, ensuring safety standards, and facilitating cost-effective practices.

What are some future trends and innovations in IoT-powered power tool switches?

Looking through the crystal ball into upcoming trends and innovations, it is evident that digitalized control mechanisms for industrial equipment, such as power tools, are set to revolutionize various sectors with their potential capabilities.

Emerging technologies in this domain foresee an era of ‘smart’ switches, capable of self-diagnosis and predictive maintenance. Furthermore, integration of IoT with artificial intelligence (AI) and machine learning (ML) will allow these devices to learn from usage patterns and optimize performance accordingly.

| Future Trends | Description | Expected Impact |

|---|---|---|

| AI Integration | Leverage intelligent algorithms for optimized performance | Enhanced efficiency & productivity |

| Predictive Maintenance | Detect issues before they occur based on data analysis | Reduced downtime & repair costs |

| Energy Efficiency | Smart management of power consumption | Lower energy costs & environmental impact |

| User Customization | Personalized settings based on user preferences or tasks | Improved user experience & usability |

| Safety Enhancements | Advanced safety features triggered by unusual activity or conditions | Increased worker safety & accident prevention |

These anticipated developments hold promising potential to redefine the landscape of industrial operations.

Conclusion

In culmination of this discourse, key points pertaining to the influence of IoT on power tool switches have been discussed in depth.

The transformative potential of IoT technology, as it revolutionizes the domain of power tool switches, has been a focal area of discussion.

Readers are thus urged to delve deeper and explore the multifaceted benefits that IoT-enabled power tools can present for their respective projects.

Key points discussed

Embracing the transformative possibilities of IoT in power tool switches, this blog post offered an insightful exploration of its potential impacts on efficiency, safety, and user experience.

Starting with an overview of the integration of IoT into power tools, it was demonstrated how this technology could significantly elevate operational efficiency.

The discussion further delved into the enhanced safety measures that IoT-enabled tools can provide by monitoring usage patterns and detecting anomalies.

Additionally, attention was given to improved user experience through customization and real-time feedback.

Notably, a critical examination of potential challenges such as data security was also integrated into the discourse.

This synthesis thus encapsulates key revelations about the future trajectory of power tool switches influenced by IoT advancements.

The transformative potential of IoT technology in revolutionizing power tool switches.

The onset of this transformative technology has the potential to completely redefine the landscape of power equipment operations, with a particular emphasis on enhancing switch mechanisms. IoT’s revolutionary impact is anticipated to be most pronounced in four key areas:

- Improved Efficiency: By integrating smart technologies into power tool switches, operational efficiency can be significantly enhanced through real-time monitoring and predictive maintenance.

- Enhanced Safety Measures: IoT-enabled switches could potentially incorporate safety features that would minimize accidents and injuries.

- Remote Control Capabilities: The advent of IoT might enable users to control their power tools wirelessly, providing an added layer of convenience.

- Energy Conservation: Smart switches could contribute towards energy conservation by optimizing usage and reducing unnecessary wastage.

These advancements suggest a future where IoT becomes integral to power tool functionality.

The benefits of IoT-enabled power tools for their projects

Exploring the myriad benefits of smart-enabled equipment for construction and DIY projects can yield significant advantages. These benefits include improved operational efficiency, robust safety measures, convenient remote control capabilities, and sustainable energy conservation.

IoT technology embedded in power tool switches provides real-time data analysis, enabling proactive maintenance to prevent sudden malfunctions that could disrupt workflow. This predictive analytics feature enhances productivity by minimizing unexpected downtime.

Moreover, safety is bolstered through automated alerts warning of potential hazards or misuse. Additionally, IoT-capabilities allow professionals and hobbyists to manipulate their tools remotely a groundbreaking convenience advancement in this field.

Lastly, these intelligent devices promote sustainability through optimizing power usage, which reduces unnecessary energy consumption. Thus, proving that adopting IoT-enabled power tools can significantly enhance various project outcomes.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd