Understanding Micro Switches

Micro switches, often referred to as snap-action switches, are compact electromechanical devices that alter the flow of electricity in a circuit upon actuation. They are typically triggered by mechanical pressure applied through a lever, button, or plunger, resulting in quick and reliable operation. The standout feature of micro switches is their ability to respond to minimal movement, providing high responsiveness and precision.

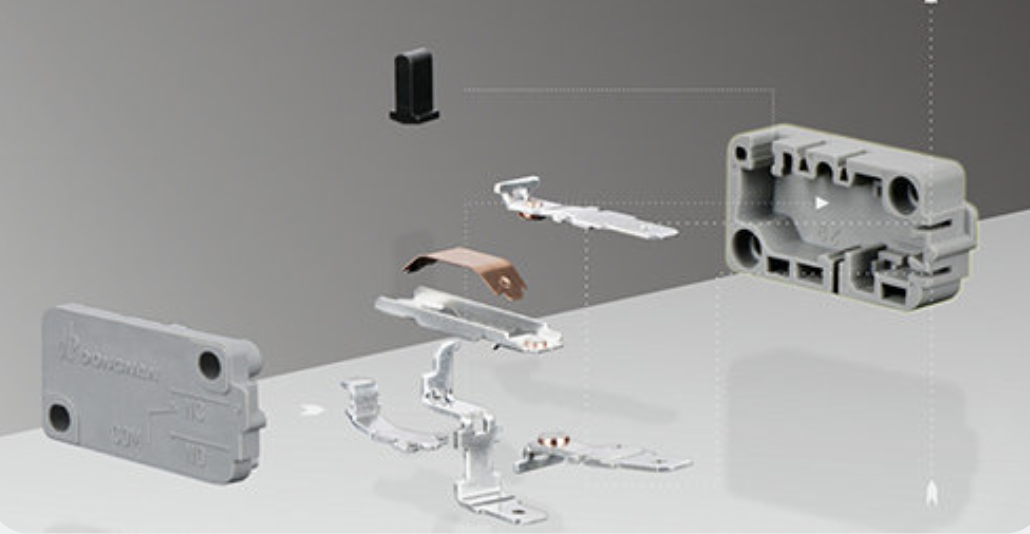

The operational principle behind micro switches is rooted in a straightforward yet efficient design. Pressing the actuator activates a mechanism that rapidly snaps the contacts into a closed or open position, facilitating quick transitions with minimal delay. This snap-action characteristic guarantees durability and longevity even in high-cycle situations. Micro switch contacts can accommodate various current levels, supporting a wide range of load capacities based on their design.

Additionally, micro switches are rugged and versatile, finding applications across numerous industries. Common sectors utilizing micro switches include:

- Automotive: Essential for safety features like seatbelt reminders, ignition systems, and door switches.

- Appliances: Integral to household devices such as washing machines, microwaves, and dishwashers for controlling various operations.

- Industrial Automation: Used in machinery for sensing applications, safety measures, and limit switches that ensure accurate positioning.

In summary, grasping the versatility and functionality of micro switches is essential for choosing the right device to meet your specific needs in 2025.

Key Features of Quality Micro Switches

As you explore the selection process for micro switches, understanding the key features that signify quality is crucial. High-quality micro switches not only ensure dependable performance but also enhance the longevity and efficiency of your devices. Below are essential features to consider:

- Actuator Types and Functionalities: Micro switches are available in various actuator designs including roller levers, plunger types, and tilt mechanisms. Each actuator type serves unique functionalities; roller levers enable smooth operation with minimal friction, ideal for automated systems, while plunger types are great for compact spaces. Understanding your application’s requirements will guide you in choosing the appropriate actuator.

- Ratings (Current, Voltage, Duration): Seek micro switches with clearly specified ratings concerning current load, operating voltage, and mechanical lifespan. Quality micro switches can usually handle higher voltage and current ratings with extended operational durations, ensuring they meet your system’s demands reliably.

- Durability and Environmental Resistance (IP Ratings): The durability of micro switches is typically defined by their Ingress Protection (IP) ratings, indicating resistance to dust and moisture. Top-tier switches often boast IP67 ratings, signifying they are dust-tight and suitable for submersion in water, making them ideal for outdoor or industrial applications.

- Size and Compatibility with Devices: Consider the physical dimensions and compatibility of micro switches with your existing devices. Micro switches are available in various sizes, and selecting one that matches your installation requirements without sacrificing performance is critical.

By taking these features into account, you can effectively choose a micro switch that efficiently and reliably meets your specific needs.

Overview of Top Micro Switch Manufacturers

The micro switch market is diverse, with multiple manufacturers showcasing unique strengths and innovations. This overview analyzes the top 10 manufacturers, emphasizing their market positioning, reputation, and distinctive offerings.

- Omron Corporation: Renowned for high-quality micro switches, Omron is distinguished by its advanced sensing technology that bolsters precision and reliability in various applications. Their durable components cater to both industrial and consumer markets.

- Honeywell International Inc.: With a rich heritage in micro switch technology, Honeywell provides rugged and versatile products designed for extreme environments. Their commitment to safety and performance makes them a trusted choice in aerospace and automotive sectors.

- Cherry Electrical Products: Specializing in mechanical switches, Cherry employs innovative designs to deliver tactile feedback and durability. Their unique key switches are particularly favored in the computer and gaming markets, focusing on user experience.

- TE Connectivity: A leader in connectivity solutions, TE Connectivity’s micro switches are engineered for harsh conditions. Their cutting-edge engineering supports diverse applications in automotive, medical, and industrial fields.

- Schneider Electric: Known for sustainability and efficiency, Schneider Electric integrates smart technology into their micro switches. Their eco-conscious manufacturing processes and advanced automation solutions set them apart from competitors.

- E-Switch, Inc.: E-Switch provides an extensive range of micro and toggle switches, offering unmatched customization options. Their adaptability to varying market needs makes them a preferred choice for OEMs.

- Panasonic Corporation: Celebrated for its innovative electronics, Panasonic’s micro switches feature enhanced sensitivity and extended lifespans, catering to high-performance applications in consumer electronics.

- Apem, Inc.: A subsidiary of the Becker Group, APEM specializes in user interface components and offers unique panel-mount solutions integrated with micro switch technology for industrial control systems.

- NKK Switches: NKK is distinguished by its aesthetic and functional designs in micro switches, accommodating various indicator types and mounting styles, appealing to both industrial and commercial sectors.

- IDEAL Industries, Inc.: Focusing on innovation, IDEAL designs products for safety and reliability. Their micro switches are built from robust materials, popular within the electrical and utility markets.

Each of these manufacturers provides something uniquely valuable, be it through innovation, reliability, or specialized focus, allowing businesses to find the optimal solution for their needs.

Comparative Analysis of Micro Switches

When selecting the ideal micro switch for your applications, it’s crucial to consider several significant parameters. This comparative analysis offers insights into the features, pricing, durability, and certifications for various manufacturers.

The comparison focuses on these key parameters:

- Features: Includes actuation force, travel distance, and overall design.

- Pricing: Examines cost per unit and bulk pricing options.

- Durability: Lifespan under standard operating conditions, emphasizing mechanical lifecycle.

- Certifications: Compliance with industry standards such as UL, CE, and RoHS.

To provide clarity, we outline the pros and cons of several leading micro switch manufacturers:

- Omron: Known for exceptional durability and extensive feature sets, though its pricing can be relatively higher.

- Cherry: Offers a variety of options with robust performance, yet may lack diverse pricing tiers.

- Honeywell: Strong in certifications and quality assurance but potential delays in delivery.

- TE Connectivity: Strikes a balance between price and quality, though their range may not cater to all specialized applications.

For a clearer understanding, a comprehensive comparison table summarizing specifications and user ratings is beneficial:

| Manufacturer | Features | Average Price ($) | Durability (Cycles) | Certifications | User Rating |

|---|---|---|---|---|---|

| Omron | High precision, multiple configurations | 5.00 | 10 million | UL, CE | 4.7/5 |

| Cherry | Mechanical, tactile feedback | 4.50 | 10 million | RoHS | 4.5/5 |

| Honeywell | Variety of actuator styles | 6.00 | 5 million | UL, CE, RoHS | 4.6/5 |

| TE Connectivity | Wide range of industrial applications | 4.75 | 10 million | CE, RoHS | 4.8/5 |

Ultimately, selecting the right micro switch necessitates a thorough assessment of these factors to ensure optimal performance and reliability tailored to your specific needs.

Buying Guide for Micro Switches

When contemplating which micro switches to choose, understanding your particular requirements is vital. Here are key factors to consider during the selection process:

- Application: Define the primary function of the micro switch. Different applications, whether automotive, industrial, or in consumer electronics, require distinct specifications.

- Environment: Evaluate the operating environment where the micro switch will be utilized. Factors such as temperature extremes, humidity, and exposure to dust or moisture can impact its performance significantly.

- Load Requirements: Understand the electrical load the switch needs to manage, including voltage, current ratings, and whether the load is resistive or inductive, all of which will influence material choices and design.

Additionally, it’s essential to evaluate potential manufacturers. Here are tips for your assessment:

- Investigate their industry reputation. Look for customer reviews and testimonials to assess reliability.

- Verify certifications and compliance with standards to ensure quality and safety.

- Evaluate their technical support and customer service offerings, as these can be invaluable during product selection and implementation.

Be mindful of common pitfalls that could lead to poor purchasing decisions:

- Neglecting specific requirements of your application, which could lead to incompatibility.

- Forgetting to consider environmental factors that may compromise functionality.

- Overlooking the total cost of ownership, including maintenance and potential downtime.

To assist in your selection process, here’s a checklist summarizing critical considerations:

- Clearly define your application.

- Assess the environmental conditions.

- Determine your load specifications.

- Research and compare manufacturers.

- Take your time in the decision-making process.

By adhering to these guidelines, you can select the micro switch that best aligns with your operational requirements, ensuring efficiency and longevity in your applications.

Frequently Asked Questions (People Also Ask)

As the demand for micro switches escalates across various industries, users often seek clarity on several key topics. Here are common questions concerning micro switches:

- What is the lifespan of a typical micro switch?

Most micro switches are rated for a lifespan of 1 million cycles under standard loads. However, factors such as environmental conditions and load types can affect this lifespan. - How do I determine the right type of micro switch for my application?

Choosing the right micro switch involves evaluating parameters like rated voltage and current, actuation force, and operating environment. It’s vital to align these specifications with your application’s needs. - What are common applications of micro switches in different industries?

Micro switches are widely utilized across various sectors, including:- Consumer electronics (e.g., home appliances)

- Automotive (e.g., seatbelt sensors)

- Aerospace (e.g., crew alert systems)

- Industrial automation (e.g., limit switches on machinery)

- What certifications should I look for in a reliable micro switch?

Look for certifications such as UL, CE, and RoHS, which confirm adherence to safety and environmental standards. - Are there specific environmental considerations I need to be aware of for micro switches?

Yes, consider operating temperature ranges, humidity levels, and exposure to dust or moisture. Selecting a switch with suitable environmental ratings, such as IP67 (dust-tight and waterproof), can be critical. - How do different brands compare in terms of reliability and performance?

While reliability can vary, leading brands typically deliver higher performance due to superior quality control, advanced technology, and extensive industry experience. Reviewing user feedback and conducting performance comparisons will help in making an informed decision.