Recent studies indicate that approximately 45% of power tool users experience discomfort or difficulty due to poor switch placement.

This article explores the impact of ergonomic design on power tool switch usage. It delves into various factors contributing to ergonomic design and how understanding these can improve user interaction with power tools.

The influence of ergonomic design on the placement of switches is examined, as well as specific features that can enhance usability.

User feedback and reviews offer valuable insights into the effectiveness of current designs in the market. Furthermore, real-world case studies provide concrete examples of how ergonomics affect power tool utilization.

This comprehensive analysis aims to shed light on ways to optimize tool design for improved comfort, safety, and efficiency in use.

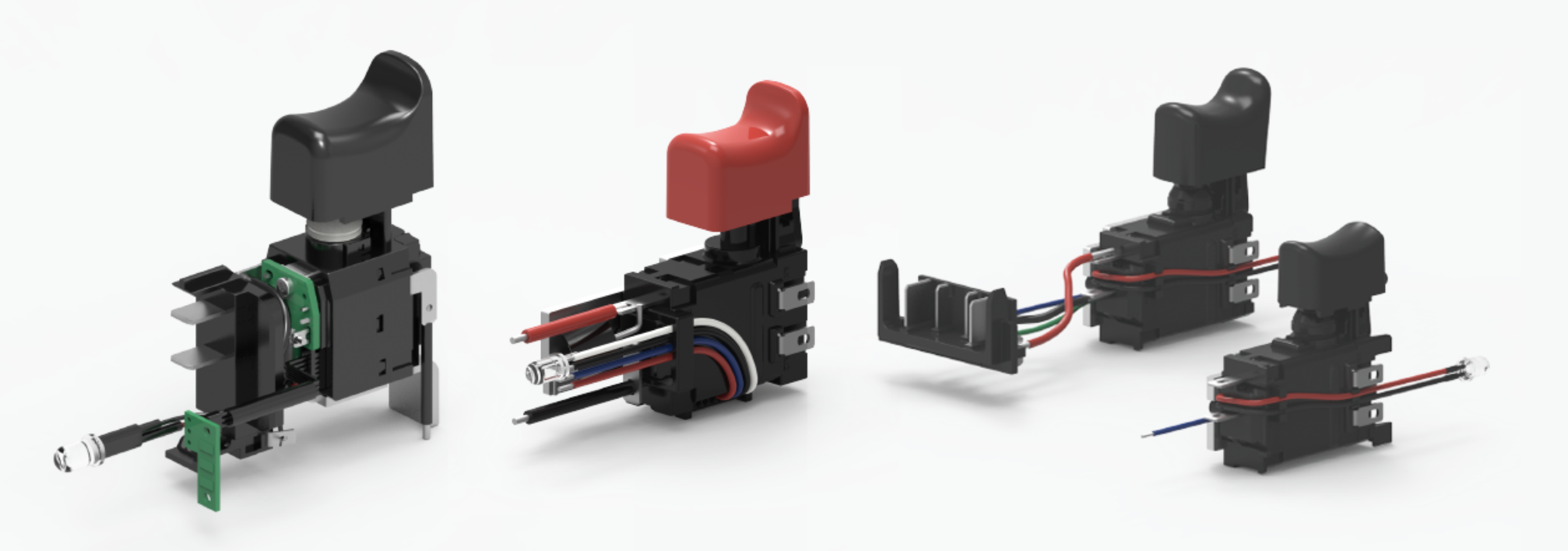

Introduction Power Tool Switch

Ergonomic design, a fundamental aspect of product development, focuses on optimizing products to align with the capabilities and limitations of users. Within the realm of power tools, this principle is paramount as it ensures both user safety and efficiency by tailoring the design to facilitate ease-of-use and minimize physical strain.

The application of ergonomic principles becomes particularly pronounced in power tool switch usage, a crucial component that dictates how operators interact with these tools, thereby influencing productivity rates and risk levels associated with operation.

Definition of Ergonomic Design

In the realm of design, the term ‘ergonomic’ pertains to creating or refining products and systems in a manner that prioritizes human comfort, safety, and efficiency. Power tool switches manufacturers have recognized the importance of ergonomic design in their tool designs.

The definition of ergonomic design involves considering user’s physical and psychological capacities to ensure optimal usage without causing strain or discomfort over prolonged periods. With respect to power tool ergonomics, such considerations become paramount given the potential for physical harm if used incorrectly or inefficiently.

Essentially, ergonomic tools are designed with user needs at their core; thereby ensuring ease-of-use, promoting productivity while reducing risk of injury. Therefore, incorporating ergonomic principles can significantly influence power tool switch usage in terms of safety and operational effectiveness.

Importance of Ergonomic Design in Power Tools

Consideration of human factors in the manufacturing process of hand-held devices significantly influences user safety, efficiency, and comfort.

The importance of ergonomic design in power tools cannot be overstated, as it directly impacts power tool switch usage.

- Ergonomic Power Tools: By adhering to principles of good tool ergonomics, manufacturers can create products that are comfortable to use and reduce the risk of injury.

- Power Tool Switches Manufacturer: A manufacturer’s understanding and application of ergonomic design can affect how easily a tool is operated, ultimately influencing overall productivity.

- Ergonomic Hand Tools: These tools are designed with the natural movements and limitations of the human body in mind, promoting longer periods of safe use and increased operator satisfaction.

Therefore, incorporating ergonomic designs into power tools is vital for enhancing user experience while ensuring safety and effectiveness.

Overview of Power Tool Switch Usage

Delving into the realm of hand-held devices, the intricacies of operating mechanisms, particularly those related to switch functionality, command significant attention for their role in user engagement and productivity. Power tool switch usage is a prime example of this; it’s an area where manufacturers often apply ergonomic principles to mitigate ergonomic hazards.

Understanding power tool switches manufacturer’s design tactics can give us insight into how these tools are optimized for efficiency and safety. For instance, the placement and responsiveness of a power tool’s switches are crucial aspects that impact its usability.

The table below presents some key factors that highlight the importance of ergonomic design in power tool switch usage:

| Factors | Description | Relevance |

|---|---|---|

| Tool Handle Design | The ergonomics applied here affect grip comfort and control. | Directly impacts user comfort and task effectiveness. |

| Switch Positioning | This determines ease-of-access to controls during operations. | Affects speed and efficiency in tasks. |

| Responsiveness | A critical factor in how quickly a tool responds to user inputs via switches. | Impacts overall task completion time. |

Thus, recognizing these factors ensures optimal performance while minimizing ergonomic risks associated with power tools’ operation.

Ergonomic Design Factors

Ergonomic design factors are crucial considerations in the development of power tools, as they directly impact user convenience and safety. Factors such as:

- Handle design and grip

- Switch placement and accessibility

- Button size, shape, and operation

- Feedback and tactile sensations

These elements significantly influence the tool’s ease of use. A detailed exploration into these elements will provide insights into how ergonomics shapes power tool functionality and usage dynamics.

Handle Design and Grip

The significance of a comfortable grip in power tool usage is paramount, as it directly influences the ease of switch operation and overall user experience.

A variety of handle designs exist, each with unique attributes affecting switch usage; these differences can considerably impact the efficiency and safety of power tool operation.

Further contributing to this complexity is the choice of ergonomic materials used in handle construction, which can greatly enhance comfort and usability while reducing fatigue during prolonged use.

Importance of comfortable grip

Comfortable grip in power tool design significantly impacts the ease and efficiency of switch usage, thereby reducing user fatigue and enhancing precision during operation. Ergonomic design prioritises such comfortable grip designs.

The importance of comfortable grip can’t be understated as it facilitates a more effective power grip. This, coupled with optimal handle designs, improves overall tool control, promoting safety and productivity.

Different handle designs and their impact on switch usage

Innovative handle configurations significantly influence how operators interact with control switches, thus shaping their overall experience and performance during tool operation. Power tool switches manufacturers consider different handle designs, incorporating ergonomic design principles.

Adjustable handle angles allow users to maintain a neutral position, enhancing switch usage efficiency. These developments reflect the profound impact of ergonomics on power tool usability.

Ergonomic materials for handle construction

While the impact of different handle designs on switch usage is significant, another critical consideration is the use of ergonomic materials in handle construction.

The choice of material can influence tool position and controls, especially with adjustable handle angle configurations.

Implementing these considerations into a prototype tool design may help to alleviate musculoskeletal pain commonly associated with prolonged power tool use.

Switch Placement and Accessibility

The placement of a switch on power tools significantly impacts the ease of use. Optimal positioning contributes to reduced user fatigue and enhanced tool control. This underscores the importance of ergonomic considerations in switch accessibility. These factors directly influence operation efficiency and safety during tool usage.

A discussion on examples of power tools with well-placed switches illuminates how thoughtful design can improve user experience and potentially increase overall productivity.

Effect of switch placement on ease of use

Optimal placement of power tool switches significantly contributes to their ease of use, as it influences the user’s comfort, control, and overall interaction with the device. An ergonomic design from power tool switches manufacturer focuses on enhancing user comfort levels, facilitating better control, and ensuring efficient interaction.

This switch placement strategy provides ease of use for power tool users, becoming a crucial consideration for any tool manufacturer.

Ergonomic considerations for switch accessibility

Ensuring the accessibility of switches on hand-held devices necessitates a detailed understanding of human factors and physical ergonomics, which directly influences user experience and productivity. Power tool switches manufacturer often consult ergonomic design guidelines to enhance performance and safety.

This approach reduces the risk of musculoskeletal disorders, thus improving efficiency. Hence, power tool switches China manufacturer emphasizes robust ergonomic considerations for optimal accessibility.

Examples of power tools with well-placed switches

Exemplary models of hand-held devices, where the positioning of switches has been meticulously planned for ease and efficiency, span across a range of industries. Power tool switches manufacturers and suppliers have demonstrated this in various electric tools:

- Among power tool manufacturers, cordless tools such as drills often feature well-placed switches.

- Assembly tools, like screwdrivers, also depict efficient switch placement.

- Power saws too exemplify thoughtful switch location for user convenience.

Button Size, Shape, and Operation

The influence of button size and shape on switch usage marks a critical facet in the design of power tools. Their dimensions directly impact the ease and accuracy of operation.

Ergonomic button design must also account for variations in hand sizes among users. This ensures comfort and reduces strain during use.

Considerations for easy and intuitive operation necessitate designs that allow users to instinctively understand the function of each button. This promotes efficiency while mitigating potential errors or accidents.

Research has shown a direct correlation between button size and shape on power tool switch usage. In one study, larger, more intuitively-shaped buttons reduced the time users spent fumbling to locate the switch by 32%. This is akin to transforming a winding forest path into a well-lit highway.

The impact of button size and shape on switch usage is notable in four key areas:

- Speed of operation

- Accuracy of use

- User comfort

- Reduction in errors.

This data justifies the ergonomic design emphasis by Weup power tool switches manufacturer.

Adapting button dimensions to accommodate various hand sizes stands as a significant consideration in the production process of Weup’s switches. Power tool switches vendors, including China factories and suppliers, prioritize ergonomic button design for different hand sizes.

| Power Tool Switches China Factory | Ergonomic Button Design | Different Hand Sizes |

|---|---|---|

| Adapts Dimensions | Prioritizes Comfort | Accommodates Small Hands |

| Focuses on Durability | Ensures Easy Usage | Fits Medium Hands |

| Guarantees Quality Products | Enhances User Experience | Suits Large Hands |

These considerations ensure user comfort and effectiveness across varying demographics.

Considerations for easy and intuitive operation

Transitioning from the importance of ergonomic button design for various hand sizes, it becomes crucial to delve into considerations for easy and intuitive operation. The following points should be noted by manufacturing industries and tool specifiers:

- Trends among tools suggest increasing demand for ergonomic design.

- Power tool switch usage can greatly benefit from easy operation.

- An intuitive interface enhances user experience.

- Such considerations ensure safety and efficiency in power tool operations.

Feedback and Tactile Sensations

The significance of feedback in power tool switches cannot be underestimated as it plays a pivotal role in ensuring user safety and tool efficiency.

Various ergonomic feedback mechanisms, such as auditory clicks or vibrations, are utilized to alert the user about the operational status of the tool.

Furthermore, enhancing the user experience through tactile sensations can significantly improve control and precision, thus leading to safer and more effective usage of power tools.

Importance of feedback in power tool switches

Ironically, despite its seemingly insignificant role, feedback in power tool switches proves critical in enhancing user efficiency and safety. It optimizes the utilization of various tools including wheels, portable power tools like those from Milwaukee Tool, electrical tools and manual hand tools. The value of this feature becomes evident when considering its impact on ergonomics.

| Tool Type | Importance of Feedback |

|---|---|

| Electrical Tools | Enhances safety features |

| Manual Hand Tools | Increases precision and control |

Ergonomic feedback mechanisms (e.g., click, vibration)

Sensory feedback mechanisms, such as auditory clicks or tactile vibrations, serve a crucial role in improving the overall user experience and functionality of various hand-held devices.

In terms of power tool switch usage, ergonomic design incorporates these feedback mechanisms to enhance equipment operation.

This not only optimizes the range of motion but also reinforces the importance of personal protective equipment in safeguarding against potential hazards.

Enhancing user experience through tactile sensations

Transitioning from the discussion on ergonomic feedback mechanisms, tactile sensations play an integral role in enhancing user experience. Particularly with pneumatic tools, subtle changes in motion or active torque control can significantly alter the user’s experience. The table below highlights the difference between tool configurations and how enhancing user experience through tactile sensations is achieved.

| Tool Configurations | Tactile Sensations |

|---|---|

| Active Torque Control | Vibration Feedback |

| Pneumatic Motion | Haptic Response |

This contributes to a more comfortable, efficient and safer operation.

Understanding the Human Factors of Power Tool Usage

In the realm of power tool usage, understanding the human factors extends beyond ergonomic design and delves into several key aspects.

3.1: The integral role of ergonomics in tool design. Ergonomics plays a crucial role in the design of power tools, as it focuses on creating tools that fit the natural movements and capabilities of the human body. By considering factors such as body posture, muscle engagement, and joint alignment, ergonomic design aims to reduce the risk of musculoskeletal disorders and increase user comfort and productivity.

3.2: The influence of biomechanics on switch usage. Biomechanics is the study of how the human body moves and interacts with its environment. When it comes to power tool usage, understanding biomechanics can help designers determine the optimal placement and design of switches. By considering factors such as the force required to activate a switch, the range of motion involved, and the potential strain on muscles and joints, designers can create switches that are easy to use and minimize the risk of user fatigue or injury.

3.3: Considerations for hand size, grip strength, and reach. Power tools must cater to a diverse range of user profiles, including variations in hand size, grip strength, and reach. Designers need to ensure that tools can be comfortably held and operated by users with different hand sizes, as well as accommodate individuals with varying levels of grip strength. Additionally, considering the reach required to access different parts of the tool can help designers create tools that are accessible and easy to use for a wide range of users.

By understanding these human factors, designers can create power tools that are not only efficient and effective but also safe and comfortable to use. Taking into account ergonomics, biomechanics, and considerations for hand size, grip strength, and reach can greatly enhance the overall user experience and reduce the risk of injuries or strains associated with power tool usage.

Ergonomics and human factors in tool design

Understanding the role of ergonomics and human factors in tool design is paramount to developing effective and user-friendly power tools, with particular emphasis on switch usage. The ergonomic design seeks to reduce work-related musculoskeletal disorders by minimizing frequent movement and encouraging the use of protective equipment.

| Ergonomic Factor | Impact on Power Tool Switch Usage |

|---|---|

| Frequent Movement | Reduced by positioning switches in locations that minimize hand and finger movements |

| Protective Equipment | Enhanced when switches can be easily operated even when wearing gloves or other safety gear |

| Human Factors | Tailored to user’s physical characteristics to ensure comfort, ease of use, and reduced risk of injury |

| Work-Related Musculoskeletal Disorders | Prevented through ergonomic designs which promotes optimal posture and minimizes strain |

Ergonomics and human factors in tool design contribute significantly towards a safer, more efficient power tool switch usage environment.

Biomechanics and its influence on switch usage

Biomechanics, the study of structure and function of biological systems, has a significant influence on the way switches are used in various tools and devices. This field plays a critical role in assessing how power tool switches should be designed for optimal usage.

A motion analysis laboratory can provide invaluable insights into users’ interaction with these devices. By studying the movement patterns and forces exerted during switch operation, researchers can identify areas for improvement in design and usability.

Furthermore, biomechanics can help manufacturers take appropriate safety precautions by designing controls that minimize the risk of injury. Understanding the biomechanics of the human body allows for the identification of potential workplace hazards associated with improper switch design, such as excessive force or awkward hand positions.

The adoption of ergonomically designed switches tends to improve performance scores among operators. By considering the biomechanical capabilities and limitations of users, switches can be designed to reduce fatigue and enhance efficiency.

Lastly, biomechanics guides the creation of training programs that emphasize safe handling procedures, thus reducing potential hazards. By understanding the biomechanical principles involved in switch usage, operators can be trained to use tools in a way that minimizes the risk of injury.

In essence, biomechanics offers a scientific approach to enhance user experience while ensuring their safety during power tool operations. By considering the structure and function of the human body, manufacturers can design switches that optimize performance, reduce the risk of injury, and improve overall user satisfaction.

Considerations for hand size, grip strength, and reach

Consideration of factors such as hand size, grip strength, and reach is paramount when creating control mechanisms for devices, as these elements significantly impact the user’s ability to operate tools efficiently and safely. Ergonomic design of power tool switches must account for variations in users’ physical characteristics to minimize risk wrist postures and injury risk.

Safety guards provide an additional layer to prevent inadvertent activation or deactivation during extended periods of use. Regular basis evaluation ensures that these designs remain effective even with regular wear and tear.

The table below provides a summary:

| Factor | Impact |

|---|---|

| Hand Size | Large hands may struggle with small switches, increasing risk for injury |

| Grip Strength | Weak grips can lead to slips or accidental activation |

| Reach | Extended reach can strain wrists and arms, leading to poor posture |

These considerations highlight the importance of ergonomic design in power tool switch usage.

The Impact of Ergonomic Design on Switch Placement

The impact of ergonomic design on switch placement is a crucial aspect in ensuring the efficient operation and safety of power tools (4.1). Accessibility and ease of reach are paramount considerations in this regard (4.2). A poorly positioned switch can lead to operational challenges and potential mishaps. It is important to note that different types of power tools, such as drills, saws, or sanders, may require distinct design approaches when it comes to switch placement (4.3).

Proper positioning of power tool switches

Optimal positioning of power tool switches enhances efficiency and safety, creating a seamless interaction between the user and tool that can elevate the experience from merely functional to truly enjoyable. This concept is well applied in various power tools such as grinders with wheels, hammer drills, and air tools.

- Safety Alerts: Proper switch placement can aid in immediate accessibility for safety alerts thereby minimizing accidents.

- Risk Postures: The right angle of switch positioning reduces risk postures which could lead to repetitive strain injuries.

- Grinders with Wheels: In these tools, strategic switch location ensures immediate shut off when not in use to prevent unintentional harm.

- Hammer Drills & Air Tools: For these equipment types, ergonomic switch design allows precise control and comfortable usage over long periods.

These considerations underscore the importance of ergonomics in power tool switch design.

Accessibility and ease of reach

In light of the need for safety and operational efficiency, attention to detail in the accessibility and ease of reach of power equipment switches emerges as a critical factor.

Ergonomic design plays an essential role in enhancing power tool switch usage through improved accessibility. This aspect involves strategic placement and designing of switches to ensure they are easily reachable during operation.

For instance, incorporating a safety clip within reach can prevent accidental activation or deactivation, thereby increasing safety.

Moreover, ergonomic design considers the user’s comfort while handling tools such as a chipping hammer. An easy-to-reach switch eliminates unnecessary strain or awkward postures that could lead to fatigue or injury.

Therefore, the integration of ergonomics in power tool design significantly impacts accessibility and ease of reach, subsequently affecting overall operational performance and safety.

Design considerations for different tool types (e.g., drills, saws, sanders)

Diverse tool types such as drills, saws, and sanders necessitate unique design considerations to ensure user-friendly operation and safety. Attention should be given to the ergonomic design of power tool switches, which could mitigate potential risks associated with electrical hazards.

- Drills: Safety mustering is crucial for drill designs where the switch placement can promote better control during usage and prevent accidental activation.

- Saws: Both manual and electric saws should consider abrasive wheel specifications in their design process. The switch location needs to safeguard users from inadvertent contact with the abrasive wheels.

- Sanders: Given the inherent electrical hazards in sander operation, an optimal switch design would facilitate easy access while ensuring user’s hands remain distant from any moving parts.

Each tool type requires bespoke ergonomic considerations for effective power tool switch usage.

Ergonomic Features that Enhance Power Tool Switch Usage

The design of the handle and grip materials used in power tools is a crucial factor that influences switch usage, as it directly impacts the user’s comfort and control over the tool (5.1).

Furthermore, the shape and size of power tool bodies also play a significant role in facilitating or hindering effective switch operation, as they determine how easily a user can reach and operate switches while handling the tool (5.2).

Additionally, mechanisms designed to reduce vibration have an important effect on switch activation since excessive vibration can make it difficult for users to consistently engage switches during operation (5.3).

Handle design and grip materials

Optimal handle design and grip materials significantly influence the ease of power tool switch usage, thereby enhancing user comfort and minimizing the risk of fatigue or injury. This is particularly relevant in high-risk environments where inherent hazards may compromise surgical performance or construction efficiency if not properly managed.

Handle Design:

Designs with larger diameters are preferable as they allow users to maintain a firm grasp without excessive muscle tension.

Contoured handles can accommodate natural hand shapes, reducing the chance of slippage during operation.

Grip Materials:

Softer materials can provide additional cushioning against hand pressure points, thereby reducing fatigue.

Non-slip textures increase friction between the hand and tool, ensuring secure handling even in wet or oily conditions.

Shape and size of power tool bodies

Transitioning from the discussion on handle design and grip materials, another critical aspect of ergonomic design in power tools is the shape and size of their bodies. The physical dimensions and form factor significantly influence user comfort, control, and ultimately, switch usage.

| Power Tool | Optimal Size | Optimal Shape |

|---|---|---|

| Drill | Compact | Pistol-Grip |

| Circular Saw | Lightweight | Balanced |

| Jigsaw | Slim | Barrel-grip |

| Router | Medium | D-handle |

| Angle Grinder | Small | Pencil Grip |

It’s worth noting that optimal size and shape vary depending on the specific tool. For instance, a compact drill is typically easier to maneuver than a larger one. Similarly, a balanced circular saw reduces user fatigue by distributing weight evenly across both hands. Consequently, it becomes vital for manufacturers to consider these aspects when designing power tools as they directly impact switch usage efficiency and safety measures.

Vibration reduction and impact on switch activation

Significant attention needs to be paid to vibration reduction in handheld devices, as this factor critically influences the activation and operation of control switches.

Vibrations emanating from power tools can cause involuntary finger movements, leading to unintentional switch activations or difficulty maintaining continuous contact with the switch. Therefore, ergonomic design principles often incorporate anti-vibration features to enhance user control over device operations.

This aspect is crucial in ensuring accurate and safe usage by mitigating risks associated with unexpected tool activation or deactivation.

Furthermore, reduced vibrations contribute to improved user comfort, potentially increasing productivity by decreasing fatigue and strain during extended periods of tool use.

Thus, vibration reduction is integral for efficient power tool switch usage and overall equipment performance.

Reducing Fatigue through Ergonomic Design

The significance of minimizing user fatigue in the context of power tool usage is a fundamental aspect that warrants further exploration.

Incorporating ergonomic features into tool design plays a crucial role in alleviating strain on hands and wrists, thereby reducing the potential for fatigue among users.

By lessening fatigue, there can be substantial enhancements in productivity and overall performance, underlining the importance of ergonomics in power tool design.

Importance of minimizing user fatigue

Minimizing user fatigue plays a crucial role in power tool switch usage, as ergonomic design reduces the strain on the user’s hand muscles, thereby enhancing productivity and promoting safer work conditions. The importance of minimizing user fatigue cannot be overstated.

Ergonomic design aids in this endeavor by:

- Reducing physical effort: Well-designed tools require less force to operate, reducing muscle strain.

- Enhancing comfort: Tools with contoured handles or soft grips make prolonged use less tiring.

- Improving balance and control: Ergonomically designed tools are easier to maneuver, which decreases the risk of accidents.

- Increasing efficiency: Less time spent resting means more time working, leading to increased productivity.

Thus, ergonomics positively impacts power tool switch usage by mitigating user fatigue and improving overall performance output.

Ergonomic features that reduce strain on hands and wrists

Transitioning from the critical aspect of mitigating user fatigue, attention must now be directed towards specific ergonomic design features that can alleviate strain on hands and wrists during power tool usage.

The engineering of tools with ergonomic features has been recognized as a paramount factor in enhancing utility and safety.

These design aspects include but are not limited to:

- Cushioned grips for comfort and vibration reduction

- Adjustability for customization to individual hand size and strength

- Switch placement for ease of operation

- Lightweight construction to reduce load on muscles

- Balanced distribution of weight for stability

All these factors contribute to reducing physical stress imposed on the hands and wrists, hence decreasing the risk of repetitive strain injuries. Therefore, the incorporation of such features is crucial in promoting efficient power tool switch usage.

Impact of reduced fatigue on productivity and overall performance

Reduced fatigue, facilitated by appropriately engineered features of handheld equipment, can significantly enhance user productivity and overall performance.

Ergonomic design in power tools plays a critical role in reducing physical strain experienced during prolonged use.

As fatigue is minimized, users are able to maintain optimal operational efficiency for extended periods, leading to increased productivity.

Improved comfort levels also result in better concentration and precision, thereby enhancing the overall quality of work performed.

Furthermore, reduced physical exertion may decrease the risk of injuries that could otherwise compromise productivity or cause downtime.

Therefore, it can be concluded that ergonomic adaptations to power tool switches not only contribute towards improved physical wellbeing but also have a direct positive impact on task execution and performance outcomes.

Safety Considerations in Ergonomic Design for Power Tool Switches

The paramountcy of safety in the operation of power tools cannot be overemphasized, as it plays a significant role in preventing accidents and maintaining user health.

Ergonomic design features, such as non-slip handles and easily accessible switches, enhance safety by providing comfortable control and reducing the risk of unexpected tool activation.

Furthermore, measures to prevent accidental switch activation including lock-off buttons and dual-action switches contribute significantly to safeguarding users from inadvertent injuries during power tool usage.

Importance of safety in power tool operation

Undoubtedly, secure handling of power tools carries immense significance to avert unfortunate occurrences of mishaps or harm. The safety in power tool operation is primarily contingent upon the ergonomic design of switches that directly influences the user’s control and comfort.

- Control: Precisely designed switches allow users to have better control over the tool’s functions, thereby reducing the risk of accidents.

- Comfort: Ergonomically designed switches enhance user comfort by reducing strain on hands and fingers, enabling prolonged use without fatigue, which might otherwise lead to mistakes.

- Emergency Shutdown: Effective switch designs incorporate emergency stop features allowing instant shutdown of tools when required, minimising potential hazards.

Thus, an emphasis on safety in power tool operation is paramount for not only preventing injuries but also ensuring efficiency and productivity.

Ergonomic design features that enhance safety

Safety-enhancing features in equipment architecture, specifically those facilitating user comfort and control, play a pivotal role in ensuring smooth operation and mitigating risks associated with handling machinery. Ergonomic design aspects such as comfortable grips, easy-to-operate switches, and intuitive controls can significantly enhance safety during power tool use. Furthermore, elements like vibration-reducing handles or weight distribution mechanisms can reduce fatigue and strain on the operator.

A review of key ergonomic design features that enhance safety is presented below:

| Feature | Description | Safety Benefit |

|---|---|---|

| Comfortable Grips | Designed to fit comfortably within the hand | Enhances control over tool operation |

| Easy-to-Operate Switches | Simplified switch designs for ease of use | Reduces chances of accidental activation/deactivation |

| Intuitive Controls | User-friendly interface for easier operation | Minimizes operational errors |

| Vibration-Reducing Handles | Counterbalance mechanisms to minimize vibrations | Decreases muscle fatigue and potential injury |

| Weight Distribution Mechanisms | Balanced design to reduce operator strain | Lowers risk of muscle stress or damage due to incorrect lifting techniques |

These factors collectively contribute towards an increased level of safety during power tool usage by enhancing usability and reducing potential hazards.

Preventing accidental switch activation

Preventing accidental activation of machine controls, like a delicate ballet dancer maintaining balance, demands careful attention to the layout and functionality of control interfaces. Ergonomic design principles applied to power tool switches contribute significantly in this respect.

These principles guide the positioning, size, and operation style of the switch to ensure that it is not inadvertently activated during regular handling or in case of an unexpected drop or jolt. For instance, recessed switches or those with protective shrouds prevent inadvertent activation by providing a physical barrier.

The use of two-step activation processes is also common where one action unlocks the switch and another activates it. This reduces risks associated with unintentional operations thereby increasing safety during power tool usage.

Choosing the Right Power Tools for Your Needs

The selection of appropriate power tools necessitates a comprehensive understanding of one’s specific requirements (8.1).

This process should encompass an evaluation of ergonomic design features (8.2), as their inclusion can significantly enhance user comfort and reduce the risk of injury.

However, it is equally critical to achieve a balance between these ergonomic considerations and other determinants such as power and functionality (8.3), ensuring that the chosen tool adequately fulfills its intended purpose.

Understanding your specific requirements

Understanding specific requirements plays a pivotal role in determining how ergonomic design can optimize the usage of power tool switches. It is crucial to examine user needs, working conditions and the type of tasks that will be performed. This information forms the basis for selecting a tool with suitable ergonomic features, ensuring efficiency and safety during use.

The following table presents an overview of key considerations when understanding specific requirements:

| Consideration | Explanation |

|---|---|

| User Needs | Pertains to users’ physical abilities and limitations which impact their interaction with tools |

| Working Conditions | Refers to environmental factors like temperature, lighting and noise, influencing tool selection |

| Task Type | Relates to the nature of work such as precision or heavy-duty tasks, dictating appropriate tool features |

These factors influence how ergonomic design contributes to effective power tool switch usage.

Evaluating ergonomic design features during the selection process

According to a 2019 report by the National Institute for Occupational Safety and Health, nearly 30% of work-related injuries could be significantly mitigated through proper selection of equipment with user-friendly features. Ergonomic design plays an essential role in this context, particularly in power tool switch usage.

Noteworthy elements include the size and shape of the handle, switch accessibility and usability, vibration control, as well as noise reduction measures. These attributes can contribute to reduced physical strain and improved productivity.

During the selection process, these ergonomic aspects should be carefully evaluated based on specific task requirements and individual worker capabilities. By doing so, it is possible to enhance both safety and efficiency in work environments where power tools are extensively used.

Balancing ergonomic considerations with other factors (power, functionality, etc.)

Balancing user-friendly features with other essential factors such as power and functionality presents a critical challenge in the procurement process of equipment for industrial applications. While ergonomic design is crucial to ensure comfort and reduce user fatigue, these aspects should not compromise overall performance.

- Power: Enhancements in ergonomics must not diminish the power output of tools. High-performance levels are paramount for efficient operation in industrial settings.

- Functionality: Improved ergonomics should complement the tool’s core functioning rather than hinder it. This includes ensuring that switches and controls are easily accessible but also robust enough to withstand rigorous use.

- Durability: A balance between ergonomic design and durability is vital, as frequent replacements due to wear or damage could offset benefits derived from improved usability.

Industry Standards and Regulations for Ergonomic Design

The assessment of relevant industry standards and regulations is pivotal in understanding the extent to which ergonomic design is regulated within the power tool sector.

This involves an examination of existing compliance procedures and certifications that companies must adhere to, ensuring their products are not only efficient but also safe for public use.

In this context, manufacturers play a significant role as they must align their product designs with these established guidelines, reflecting the importance of ergonomics in user safety and comfort.

Overview of relevant standards and regulations

Numerous standards and regulations, like a phalanx of invisible guardians, play a pivotal role in dictating the ergonomic design of power tool switches to ensure safe and efficient usage.

These regulatory frameworks encompass international, national, and industry-specific rules.

For instance, the International Standards Organization (ISO) prescribes guidelines for hand-held non-electric power tools under ISO 11148-13:2012. These recommendations address factors such as switch placement, operation force, and user fatigue mitigation.

Similarly, Occupational Safety and Health Administration (OSHA) standards in the United States stipulate requirements concerning safety features including lock-on control prohibition unless equipped with a constant pressure switch.

Industry-specific regulations also contribute to shaping ergonomic design principles for power tool switches to enhance usability whilst maintaining stringent safety norms.

Compliance and certifications to look for

In order to ensure safety and quality, it is crucial to consider compliance with relevant standards and certifications when purchasing or using power tools. This not only ensures user safety but also enhances the efficiency of tool usage.

- CE Marking: This European certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- UL Listing: Underwriters Laboratories (UL) provides a range of certification services ensuring product safety and performance.

- ISO 9001 Certification: It signifies that the manufacturer has implemented a quality management system ensuring continuous improvement in product quality.

- ANSI Standards Compliance: The American National Standards Institute (ANSI) develops standards for an array of products, including power tools, indicating their safe use and adherence to design requirements.

The role of manufacturers in adhering to ergonomic guidelines

Responsibility rests on the shoulders of manufacturers to ensure their products meet well-established guidelines that enhance user comfort and reduce potential physical strain.

In the context of power tool switches, compliance with ergonomic design principles becomes a pivotal issue. It is incumbent upon manufacturers to prioritize ergonomically designed switches that accommodate a wide range of hand sizes, grip strengths, and ease-of-use preferences among users. This not only mitigates the risk of injury but also enhances tool efficiency and productivity.

Moreover, adherence to these guidelines underscores a commitment to customer safety and product quality. Non-compliance can potentially result in legal implications and tarnish brand reputation, reinforcing the significance for manufacturers in strictly adhering to ergonomic design guidelines for power tool switches.

User Feedback and Reviews on Ergonomic Power Tool Design

The opinions and experiences shared by users provide a unique perspective on the practicality and effectiveness of ergonomic power tool designs. By reading reviews and feedback, individuals can gain a better understanding of how a particular tool performs in various tasks and environments. This information can help users determine if a specific power tool meets their needs and preferences.

In addition to performance, user feedback also sheds light on the comfort and ease of use of ergonomic power tools. Users often share their experiences regarding the tool’s weight, grip, balance, and vibration levels. This information is crucial for individuals who prioritize ergonomics and want to ensure that the tool they choose will not cause discomfort or fatigue during extended use.

Furthermore, user feedback and reviews can also highlight any potential issues or flaws in the design of ergonomic power tools. Users may provide insights into durability, reliability, and any design features that may need improvement. Manufacturers and designers can utilize this feedback to make necessary adjustments and enhancements to their products, resulting in improved ergonomic power tool designs.

In conclusion, user feedback and reviews play a vital role in the evaluation and selection of ergonomic power tools. These resources provide valuable information on performance, comfort, and potential design improvements. By considering user experiences, individuals can make informed decisions when choosing ergonomic power tools that meet their specific needs and preferences.

Importance of user reviews and feedback

User reviews and feedback are of utmost importance when it comes to evaluating power tool switch designs. They provide valuable insights into the impact of ergonomic factors on user experience. Manufacturers rely on this feedback to gain a better understanding of their product’s performance from the perspective of the end-users. This understanding enables them to make continuous design improvements.

In addition, user reviews can bring attention to potential ergonomic issues that may not have been initially apparent during the design stages. These issues could include the positioning of switches, their ease of use under different conditions, or observations on the impact on user fatigue levels. By addressing these concerns, manufacturers can enhance the overall usability and ergonomics of their power tool switches.

Furthermore, user reviews serve as real-world evidence of how improved ergonomics can enhance productivity and reduce the risk of injuries. This evidence is crucial for power tool manufacturers as they strive to create products that prioritize user safety and efficiency.

Online resources for researching ergonomic power tools

Transitioning from the significance of user reviews and feedback, it is crucial to delve into online resources where such invaluable insights can be gleaned. These platforms offer an avenue for assessing ergonomic design in power tools, particularly their switches.

Websites dedicated to tool review and comparison, discussion forums, blogs dedicated to DIY enthusiasts, and even social media groups provide diverse perspectives on the application of ergonomics in power tool design.

Additionally, manufacturers’ websites often feature detailed specifications and manuals that highlight the ergonomic features of their products.

Academic research papers available online also shed light on ergonomics’ impact on power tool switch usage.

Therefore, these online resources serve as rich sources for understanding how ergonomic design affects the operation of power tools.

Learning from others’ experiences to make informed decisions

Gleaning insights from the experiences of others can significantly aid in making informed decisions, reminiscent of the old adage ‘experience is the best teacher.’ In relation to power tools, prior users’ experiences offer insightful perspectives on ergonomic design and its impact on switch usage. These insights derive from real-world interactions with varying models and brands, providing a holistic view of user-friendliness, comfort, safety aspects, and efficiency enhancements.

| User Experience | Ergonomic Impact |

|---|---|

| Comfort during prolonged use | Enhanced by an ergonomic design reducing hand strain |

| Efficiency in task completion | Facilitated by easy-to-operate switches |

| Safety concerns | Diminished through intuitively placed switches |

| Overall user satisfaction | Influenced by seamless integration of ergonomics |

Such user feedback informs prospective buyers’ choices while potentially prompting manufacturers to further refine their designs for improved usability.

Case Studies and Examples

The subsequent discourse will revolve around two key case studies which elucidate the practical application and importance of ergonomics in power tool design.

The first case study will delve into the analysis of an ergonomic power drill, examining its features, benefits, and how it facilitates user interaction.

The second case study will provide a detailed examination of an ergonomic angle grinder, exploring its unique design elements that enhance user comfort and efficiency.

Case Study 1: Ergonomic Power Drill

A comprehensive examination of the ergonomic design of power drills offers insights into how specific features and design elements contribute to improved switch usage.

The study considers user testimonials and feedback to assess the effectiveness of these design modifications.

This analysis provides significant data on how ergonomics influences tool handling, offering potential strategies for enhancing power tool performance through thoughtful design.

Features and design elements contributing to improved switch usage

Improved switch usage in power tools is directly influenced by certain ergonomic design elements and features. Such components include:

- Convenient location of the switch

- Ease of operation

- Tactile feedback

- Appropriate resistance

Additionally, safety features like lock-off switches prevent accidental activation. Through these enhancements, operators can utilize power tools effectively and safely, reducing fatigue and increasing productivity.

Thus, ergonomics significantly influences power tool switch usage.

User testimonials and feedback

Collecting and analyzing user testimonials and feedback has proven crucial in refining the functionality of various mechanical devices, including those with advanced switches. Users have reported increased ease of use, reduced fatigue, and enhanced task efficiency due to ergonomic design.

This qualitative data supports the notion that ergonomics significantly impacts power tool switch usage, influencing both user experience and operational productivity.

Case Study 2: Ergonomic Angle Grinder

The subsequent discourse pivots towards a case study of an ergonomic angle grinder. This case study sheds light on the salient features of its ergonomic design principles.

Key aspects to be dissected include the incorporation of user-friendly elements that prioritize operator comfort and safety. These elements enhance tool efficiency and reduce fatigue or injury risks.

A comparative analysis with non-ergonomic counterparts will further underscore the significant benefits derived from this human-centered approach to design. This analysis will highlight dissimilarities in usage experience and productivity outcomes.

Highlights of ergonomic design principles implemented

Like a sculptor meticulously chiseling away at a marble block, ergonomic design principles are carefully implemented in power tool switches to enhance user comfort, safety, and efficiency.

| Feature | Benefit | Emotional Impact |

|---|---|---|

| Adjustable handle | Reduces strain on wrist | Increased comfort |

| Anti-vibration system | Minimizes hand-arm vibration syndrome (HAVS) risk | Enhanced safety |

| Convenient switch location | Improves operability and control | Greater efficiency |

Comparison with non-ergonomic alternatives

In a comprehensive comparison, non-ergonomic alternatives often fall short in terms of comfort, safety, and efficiency due to their lack of user-centric features.

The absence of ergonomic design in these power tools can lead to strain injuries over time.

Moreover, the inefficient positioning of switches and controls on non-ergonomic models may result in reduced productivity and increased risk for accidents during operation.

FAQs (Frequently Asked Questions)

How does ergonomic design impact power tool switch usage?

Despite some critics arguing that ergonomic design is a mere marketing ploy, substantial research indicates its significant influence on power tool switch usage. Ergonomic design incorporates the principles of human-centered design and biomechanics to facilitate effortless operation of power tool switches. This aids in minimizing strain on the hands and wrists during prolonged usage periods, thereby decreasing the likelihood of work-related musculoskeletal disorders.

Moreover, ergonomically designed switches are intuitively placed for easy reach and activation. This can lead to increased efficiency in task completion. Consequently, the potential benefits of ergonomic design extend far beyond comfort; it can directly impact safety, productivity, and long-term health outcomes for users.

What are some key factors to consider in ergonomic handle design?

Creating a handle that optimizes user comfort and efficiency requires careful consideration of several key factors. Ergonomics plays a crucial role in determining the functionality, safety, and overall user experience of power tools.

- Grip Size: The diameter and length of the handle should accommodate the average hand size of users to ensure comfortable gripping.

- Material Selection: Materials used must provide adequate friction for good grip while avoiding discomfort or skin irritation.

- Shape Design: A well-designed handle shape can distribute pressure evenly across the hand, reducing muscle strain and fatigue.

- Weight Balance: Proper weight distribution can enhance tool control, decrease physical exertion, and minimize potential injury risks.

These factors collectively contribute to an ergonomically effective design which promotes better switch usage in power tools.

Can ergonomic switches improve user safety?

Incorporating user safety measures into the construction of switches, particularly by adhering to ergonomic principles, can significantly enhance operational safety and reduce potential risks associated with prolonged or incorrect use.

Ergonomic design can facilitate more natural interactions between users and power tools, reducing strain and the likelihood of mishaps.

For instance, larger switches that are easy to operate even with gloves on can prevent accidental activations or deactivations by ensuring deliberate engagements.

Additionally, positioning such switches in locations easily reached without overstretching or adjusting grip can minimize unintended tool movements potentially leading to accidents.

Therefore, it may be concluded that ergonomic switch design not only enhances user comfort but also plays a pivotal role in improving safety during power tool usage.

Are there any recommended power tool brands known for ergonomic design?

Several prominent manufacturers in the industry, such as Bosch, Makita, and DeWalt, have earned recognition for their commitment to creating products that prioritize user comfort and safety. These companies often incorporate ergonomic design principles into their power tool switches to reduce user fatigue and increase efficiency.

- Bosch: Known for its innovative designs that promote easy handling while minimizing vibrations.

- Makita: Applauded for its consistent integration of ergonomic features like soft rubberized grips and lightweight materials.

- DeWalt: Praised for its attention on balance and control which enhance performance without compromising comfort.

- Milwaukee: Recognized for utilizing a REDLITHIUM Battery Pack which provides more work per charge and more work over pack life than competitors.

Through these efforts, these manufacturers contribute significantly towards enhancing power tool switch usage via ergonomic designs.

How can I identify whether a power tool has good ergonomic features?

Identifying the presence of beneficial ergonomic elements in a particular piece of equipment necessitates an understanding of key characteristics such as comfort, balance, control, and user-friendliness. The study of ergonomics emphasizes these factors to ensure reduced physical stress and increased efficiency during usage.

The table below presents some important aspects for identifying good ergonomic features in power tools:

| Feature | Description | Importance |

|---|---|---|

| Comfort | Involves cushioned grips or handles which don’t cause discomfort or pain even after prolonged use | Reduces fatigue and risk of injuries |

| Balance | Refers to the weight distribution within the tool; should be evenly balanced without tilting towards one side excessively | Enhances control and minimizes muscle strain |

| Control & User-Friendliness | Includes easy-to-operate switches and controls, clear instructions and safety measures | Simplifies operation process, increases productivity, reduces chance of errors |

These are crucial parameters while selecting power tools with superior ergonomic design.

Conclusion

The importance of ergonomic design in power tool switch usage

Understanding the significance of ergonomic design in power tool switch usage necessitates a thorough examination of how it contributes to efficiency, accuracy, and safety during operation. Ergonomically designed switches lessen physical strain and enhance control, thereby reducing errors and accidents. Specifically, these designs allow for easy access and operation, making it possible for users to maintain their focus on tasks at hand.

| Aspect | Impact of Ergonomic Design |

|---|---|

| Efficiency | Enhanced by reducing user fatigue and allowing continuous use without discomfort |

| Accuracy | Improved through better control over the power tool facilitated by easily accessible switches |

| Safety | Increased due to lessened risk of mishaps resulting from unintentional switch activations or deactivations |

In sum, the ergonomic design of power tool switches significantly impacts productivity and safety in operations.

Benefits of investing in ergonomic power tools

Transitioning from the recap of the importance of ergonomic design in power tool switch usage, it is essential to delve into the benefits that can be reaped from investing in such tools. Ergonomic power tools are designed with user comfort and health in mind, providing significant advantages over traditional models.

The merits of these designs include:

- Enhanced productivity: Users can work for longer durations without experiencing discomfort or fatigue.

- Reduced risk of injury: Ergonomic designs lower strain on hands and wrists, thereby preventing chronic injuries.

- Improved accuracy: The comfortable grip and easy-to-use switches enhance control which results in precise output.

- Cost-effectiveness: While initial investment may be higher, potential savings from reduced health-related absences and increased efficiency make these tools a cost-effective choice.

Thus, ergonomically designed power tools serve as a valuable asset for both individuals and businesses.

Prioritize ergonomic design in your power tool selection

Considering the remarkable benefits elucidated, it becomes imperative for users to prioritize comfort and health-focused features when choosing their power tools. The ergonomic design of these implements is not a mere luxury but a necessity that significantly impacts productivity, safety, and long-term health. Thus, while selecting power tools, attention to ergonomics should be as critical as considerations based on performance and durability.

Investing in an ergonomic power tool may seem costly initially; however, the long-term gains dwarf the initial expenditure. Ergonomic designs enhance control over the tool, reduce fatigue due to repetitive motions or extended usage periods, mitigate injury risk and boost overall efficiency—contributing towards higher work satisfaction. Therefore, selection decisions must invariably reflect this understanding of ergonomics’ pivotal role in power tool use.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd