Constantly connecting the world, Female IEC Connectors play a pivotal role in power transmission and electronic devices. This comprehensive guide explores the various types of Female IEC Connectors, their design features, applications, advantages, and considerations for choosing an appropriate connector.

It aims to provide valuable insights about these integral components that help power and connect numerous electrical devices.

A special section is dedicated to installation and maintenance procedures to ensure longevity of these connectors, followed by a section answering frequently asked questions pertaining to this subject matter.

By understanding the functionality and diversity of Female IEC Connectors, readers will be better equipped to make informed decisions regarding their selection and use in various applications.

As such, this guide serves as an authoritative resource on everything one needs to know about Female IEC Connectors.

Introduction IEC Connectors

Female IEC connectors are crucial elements in the electrical industry, serving as standardized attachments that facilitate secure and efficient power transmission between various devices. As an integral part of many systems and equipment, they contribute significantly to the overall performance and safety of electrical installations.

This comprehensive guide will provide a detailed examination of these connectors, elucidating their definition, importance, relevance, and application in the contemporary industrial landscape.

Definition of female IEC connectors

In the realm of electrical connectivity, IEC female connectors play an integral role, offering secure and reliable connections for a plethora of electronic devices. The term ‘female’ in this context refers to the receiving end of a connection system that is generally manufactured by a female IEC connectors manufacturer. They are fundamentally designed for standard interconnection connector applications.

- Female Appliance Outlet: This is often employed in appliances where direct plug-in capabilities are required.

- Types of Connectors: There’s an array of types available, each serving unique purposes based on their design and functionality.

- Electrical Connector: This type specifically caters to establishing an electrical circuit by joining electrical terminations together.

These components offer versatility across different industries, making them essential in creating effective and efficient electronic systems.

Importance and relevance in the electrical industry

Given their integral role in maintaining secure and reliable connections for a multitude of electronic devices, the significance of these components cannot be overstated within the electrical industry. The importance and relevance of female IEC connectors are underscored by their ubiquity in various applications. As a standard for building receptacles, they ensure that electronic equipment operates efficiently and safely.

A prominent female IEC connectors manufacturer plays a crucial part in the supply chain, providing high-quality components to meet industry demands. Moreover, with globalization increasing competition among businesses, sourcing from a reputed female IEC connectors China supplier can offer cost-effective solutions without compromising on quality or reliability.

These connectors function as an appliance inlet to establish secure connections, proving indispensable to the operation of numerous electronic devices.

Types of Female IEC Connectors

Diving deeper into the subject, it becomes evident that there are diverse types of Female IEC Connectors, each having unique applications and specifications.

Notable among these are the C13, C15, C19, C21, and C23 connectors which will be elaborately discussed in the following sections.

Their various characteristics such as design differences, temperature ratings, power delivery capabilities and usage scenarios will form the core discussion points for a comprehensive understanding.

C13 Connector

Renowned for its versatility and ubiquity in everyday electronics, the C13 connector is a common type of female IEC connector that plays an integral role in powering a wide array of devices. A product from reputable female IEC connectors manufacturers, this type offers multiple advantages.

- Type: The C13 connector is one of the most popular female versions, ensuring compatibility with various devices.

- Ground Pin: It features three pins, including a ground pin which provides safety against electrical shocks.

- Current Rating: This connector can manage a current rating up to 10A, making it suitable for many applications.

- Temperature Rating: It has a temperature rating of -25°C to +70°C, enabling use under diverse environmental conditions.

- Wide Usage: Its ability to power different devices makes it ubiquitous in homes and offices alike.

C15 Connector

Transitioning from the popular C13, the C15 connector steps up to the plate in terms of heat resistance. As they say, ‘not all heroes wear capes’, and this holds true for the unassuming yet robust C15 connector that excels in environments with high temperatures. This variant is produced by various female iec connectors manufacturers worldwide, including numerous female iec connectors china manufacturers.

The C15 connector is one of those common types that makes a difference within certain industries due to its superior performance under intense heat conditions. It’s designed specifically to create secure connections despite being subjected to elevated temperatures not typically suitable for other connectors like the earlier mentioned c connector. Thus, when it comes to reliability and durability amidst challenging situations, the C15 connector undoubtedly stands out.

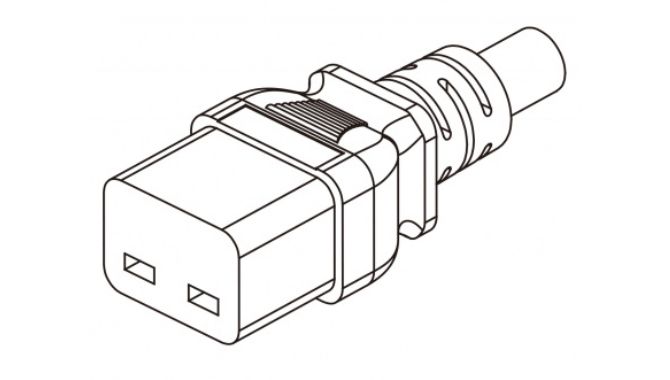

C19 Connector

Moving up the scale of power and durability, we encounter the C19 connector, an essential component known for its capability to handle higher currents and offer steadfast connections in demanding environments. Manufactured by several female iec connectors manufacturers, this robust piece is often produced in a female iec connectors china factory.

| Feature | Description | Application |

|---|---|---|

| C Inlet | Designed to be mounted on a power cord | Used in power supply units that require higher current ratings |

| Female Mating Outlet | Connects directly with male plugs | Useful for heavy-duty applications |

| Screw Terminals | Allows firm connection between wires and connector | Employed in instances where direct wiring to the device is necessary |

With these distinct features, C19 connectors are integral parts of various high-power appliances and industrial equipment.

C21 Connector

Delving into the domain of higher power requirements, we encounter the C21 connector, a robust component known for its ability to handle significant electrical currents. As a leading female IEC connectors manufacturer, the production of this connector adheres to rigorous international standards that ensure reliability and safety.

The C21 connector is primarily used in conjunction with standard AC plugs and compatible cord connectors designed to meet specific voltage and current specifications. This form of connection is commonly utilized within high-capacity power distribution units that require stable and continual energy supply.

Renowned female IEC connectors China vendors emphasize the importance of these components in maintaining efficient electronic infrastructure systems. Their application spans across diverse sectors owing to their versatility, thereby making them an indispensable part of modern power distribution networks.

C23 Connector

In the grand universe of power connectors, none stands as a more formidable titan than the C23 connector. This device is produced extensively by numerous female iec connectors manufacturers across the globe, due to its various applications and wide range of use.

The C23 connector finds its utility on a diverse spectrum of electronic boards, making it an essential component in many industries.

Often procured from a reputable female iec connectors factory, these units are meticulously designed to meet high standards. Female iec connectors suppliers ensure that these components comply with international regulations while providing optimal performance. Furthermore, vendors dealing with female iec connectors offer a vast selection tailored to cater to different customer requirements.

Thus, this underscores the pivotal role of the C23 connector within myriad electrical applications.

C25 Connector

Transitioning from the C23 connector, another variant in the family of female IEC connectors is the C25 connector. This type of connector, as produced by a female IEC connectors manufacturer, serves diverse applications across several sectors.

- Structure: The C25 connector deploys a distinct structural design which includes three pins – two horizontal and one earth pin placed vertically.

- Mating Appliance Outlet: It mates with a specific appliance outlet designed to accommodate its unique form factor.

- Internal Connectors: Internally, it features multiple connectors for easy installation and secure operation.

- Cable Connections: Primarily utilized for cable connections, this kind of female IEC connectors ensures reliable data or power transmission.

In essence, understanding these intricate details about each IEC connector like the C25 aids in selecting suitable cable connectors that align with specific requirements ensuring optimal performance.

C27 Connector

Moving forward in the classification of international connectors, we encounter the C27 connector. This type of connector is commonly used by a variety of manufacturers such as Weup Female IEC Connectors Manufacturer. It functions as an alternative power entry connector and finds utility in numerous electronic appliances.

The C27 Connector belongs to the category of appliance couplers, providing seamless power transmission between various devices. An interesting feature is its polarized design, which ensures correct orientation during connection, thereby promoting safety and reducing risks associated with incorrect power interface.

Another noteworthy attribute is its slide-in mechanism. The slide-in connector makes it easy to connect or disconnect from the device without requiring any tools. Therefore, the C27 connector provides reliable, efficient and safe power connectivity solutions for a broad range of applications.

Design and Features

The subsequent discourse delves into the design and features of female IEC connectors. It focuses on three main aspects: physical appearance and dimensions, materials employed in their manufacture, and key design elements and features.

The physical appearance and dimensions of female IEC connectors play a crucial role in their compatibility with different equipment types. Connectors come in various sizes and shapes, and it is important to select the right one that fits the equipment properly. Additionally, the dimensions of the connectors determine their overall footprint and space requirements.

The materials used in the manufacture of female IEC connectors also contribute to their performance and durability. Connectors are typically made from high-quality materials such as metal or plastic. The choice of material depends on factors such as the intended application, environmental conditions, and desired level of durability.

Lastly, the design elements and features of female IEC connectors are essential in ensuring their functionality and ease of use. These features may include locking mechanisms, polarized pins, and grounding options. Each design element serves a specific purpose and contributes to the overall performance and safety of the connector.

A comprehensive understanding of these design and feature aspects is crucial for selecting suitable connectors for specific applications. It allows users to make informed decisions based on the requirements of their equipment and the environment in which they will be used.

Physical appearance and dimensions

Resembling relics of a bygone era, the physical appearance and dimensions of female IEC connectors are crucial elements that greatly influence its compatibility and functionality in electrical devices. These attributes contribute to their seamless integration into different computing devices.

- Female IEC connectors, due to their standardised sizes and shapes, can be easily fitted into various device dimensions. This universality fosters ease of installation across an array of electrical appliances.

- The physical appearance is often compact and robust, making it suitable for tightly packed electronic settings.

- These connectors typically have a reliable shield connection which ensures safety while also enhancing the overall performance of connected devices.

In essence, understanding the physical appearance and dimensions of female IEC connectors is vital as they represent standardised appliance connectors designed for modern computing systems.

Materials used in manufacturing

Materials of construction for these appliance connectors play an integral role in their durability and functionality, substantially influencing their performance in diverse electrical settings. Specifically, female IEC connectors are typically manufactured from robust materials such as copper alloy, brass or phosphor bronze with nickel or gold plating. These materials contribute to the reliable data transmission and protection against corrosion, which are essential features for standardized appliance connectors.

The use of high-quality plastic housing is common to provide insulation and protection against electrical shock. Furthermore, the choice of material also aligns with national appliance coupler standards that govern the safety and reliability aspects of these components.

Therefore, understanding the materials used in manufacturing is critical when selecting female IEC connectors for specific applications.

Key design elements and features

Key design elements and features play a crucial role in the functionality of essential components such as female IEC connectors. These connectors are meticulously designed to fulfill specific electrical requirements and ensure compatibility with various equipment.

Several significant attributes influence the performance of female IEC connectors. One of these attributes is the use of barrel connectors, which provide reliable power connections. Another important aspect is adherence to the American National Standard for Electric Power Systems and Equipment, which ensures that safety standards are met.

The selection of a suitable power plug according to geographical location or device compatibility is also a key design element. Additionally, female IEC connectors are designed with a defined degree of protection against dust, water ingress, or mechanical impacts.

These key design elements and features contribute to the efficient functioning of female IEC connectors. They ensure a stable electric power supply while minimizing potential risks related to electricity usage.

Applications of Female IEC Connectors

Applications of female IEC connectors are extensive and diverse, ranging from IT equipment to industrial machinery. Given the crucial role these connectors play in ensuring effective power transfer and signal transmission, their utilization spans various industries including audiovisual technology, medical devices production, telecommunications and many more.

Each application presents unique demands for connector design, consequently driving advancements in IEC connector technology to meet these specific requirements.

Computer and IT equipment

In the realm of Computer and Information Technology equipment, female IEC connectors play an integral role in ensuring seamless data transmission and power supply.

These connectors are a crucial component of laptop power supplies, where they serve as an interconnection plug for transmitting electricity from the mains to the device.

Furthermore, they are integral to uninterruptible power supply (UPS) units, facilitating a continuous flow of energy to prevent data loss during power outages.

Network routers also employ these connectors, using them for stable power provision and reliable network connectivity.

In addition, other devices such as a female DTE adapter or an angled AC adapter utilize female IEC connectors for efficient energy transmission and secure connections.

Therefore, their importance in computer and IT equipment is undeniably pivotal.

Audio and visual devices

Transitioning from the realm of computers and IT equipment, the scope of female IEC connectors extends into audio and visual devices. These connectors play a quintessential role in ensuring seamless transmission of audio-visual data.

| Electrical Appliances | Application |

|---|---|

| Home Theater Systems | Audio Applications |

| Television Sets | Visual Applications |

Notably, the appliance weight influences the choice of these connectors – heavier appliances necessitate robust connectors with a higher wire gauge. In North America, American plugs are commonly used in conjunction with these IEC connectors to facilitate easy connection to an extension cord.

The table below illustrates this relationship:

| Wire Gauge | Appliance Weight (in lbs) |

|---|---|

| 14 AWG | Up to 50 |

| 12 AWG | 50-100 |

Evidently, understanding these aspects is crucial for optimal performance of audio and visual devices.

Industrial machinery and equipment

Delving into the realm of industrial machinery and equipment, these devices also utilize specified connectors to ensure their efficient operation.

Female IEC connectors are integral components in a plethora of hot household appliances and industrial machinery due to their robust design that can withstand high temperatures. These connectors adhere to various transmission standards, such as American standard or national standards, which dictate parameters for secure power connections.

In particular, they facilitate the smooth transfer of electrical supply from source to device, thereby promoting optimal performance. The versatility of female IEC connectors underscores their importance not only in domestic settings but also in industries where reliable power supply is paramount for maintaining round-the-clock operations and ensuring safety protocols are met.

Medical devices

Transitioning from the application of female IEC connectors in industrial machinery and equipment, an equally significant domain where these components are indispensable is in medical devices.

Medical appliances often necessitate stringent safety standards, including specific sockets adhering to British standard, which ensures compatibility and reliable connections. Female IEC connectors cater to these requirements effectively. Their design accommodates AWG wire sizes allowing for a broad spectrum of applications across various medical devices.

Moreover, these connectors aid in classifying appliances with protection class based on their insulation level and potential risk factor; this includes variation protection class I that signifies appliances providing basic insulation with additional safety measures.

Furthermore, different wire sizes offer flexibility in power transmission requirements, thereby supporting diverse functionalities within the realm of medical equipment.

Telecommunications equipment

According to a recent report by the Telecommunications Industry Association, telecommunications equipment market is expected to reach $530 billion by 2025, indicating an increased demand and reliance on efficient electrical components such as standardized connectors.

In this context, female IEC connectors serve as pivotal elements in facilitating safe and reliable connections. Their common application involves connection of devices to wall outlets where the connector’s screw bears the weight of ensuring secure contact.

Notably, these connectors can accommodate both grounded and nongrounded applications, with a dedicated ground wire for added safety in grounded scenarios. Moreover, they are designed to withstand varying environmental conditions making them suitable for different settings within the telecommunications industry.

These features underscore their critical role in meeting emerging demands within this growing sector.

Advantages of Female IEC Connectors

Safety and reliability

Safety and reliability are paramount when considering the use of female IEC connectors in any electrical setup. These components, built to international standards, ensure a safe and secure connection that significantly reduces the risk of electric shock or fire due to faulty connections. The design incorporates features like insulation displacement, which provides additional safety by preventing accidental contact with live parts.

Moreover, their robust construction ensures long-term reliability under various operating conditions.

In terms of reliability, female IEC connectors demonstrate consistent performance over time. Their ability to maintain stable electrical connections even under heavy load conditions contributes significantly to system uptime. Furthermore, they exhibit excellent resistance against environmental factors such as temperature fluctuations and humidity which helps in extending their operational lifespan.

Compatibility with various devices

Compatibility across various devices is a salient feature of these globally standardized components, much like a universal key that can unlock doors in different countries.

Female IEC connectors are engineered to facilitate this versatility, being compatible with an extensive range of electronic equipment, such as computers, monitors, printers and power supply units. This compatibility extends to both domestic and commercial appliances.

The design ensures the smooth transmission of electrical power from source to device without the need for multiple adapters or converters. Furthermore, they are designed to maintain optimal performance under varying operating conditions.

With global standardization at its core, this compatibility feature enhances efficiency and safety while allowing users to connect their devices seamlessly across different platforms and geographical locations.

Ease of installation and removal

Ease of installation and removal is another notable feature that enhances the user experience with these globally standardized components. For most female IEC connectors, the process does not require any specialized tools or technical expertise. With a simple push-in, twist, and pull-out mechanism, users can effortlessly establish or disconnect connections for various appliances and equipment. The design of these connectors also includes clear markings to guide correct alignment during installation.

Moreover, their structure has been engineered to withstand repeated installations and removals without compromising performance and durability. In cases where changes in configuration are frequently needed, such as in testing environments or mobile setups, this feature significantly reduces downtime and potential damage risks. Therefore, providing both convenience and reliability in diverse applications.

Flexibility and versatility

Having explored the simplicity associated with the installation and removal of female IEC connectors, it is essential to delve into another significant attribute: their flexibility and versatility.

Female IEC connectors are designed not only for diverse applications but also to cater to multiple devices. Their structure enables them to be used in different settings, including both commercial and residential environments. They can connect a broad spectrum of electronic equipment such as computers, televisions, amplifiers, among others.

Additionally, they come in various types —each designed for specific voltage and current ratings which further increases their versatility.

This ability to accommodate varying electrical requirements makes female IEC connectors an indispensable tool in ensuring the smooth operation of numerous electronic devices across several platforms.

Common Female IEC Connector Standards

The exploration of Female IEC Connectors would not be complete without an insightful delve into the prevailing standards that govern their design and operation. Crucial among these are the IEC 60320, which provides specifications for general purpose connectors and inlet configurations, and its counterpart, the IEC 60309 that outlines specific requirements for industrial plugs, socket-outlets and couplers.

Also noteworthy are the subsets of the latter – IEC 60309-2 detailing dimensional interchangeability requirements and IEC 60309-4 focusing on switching devices and their combination with plugs, socket-outlets, couplers for industrial purposes.

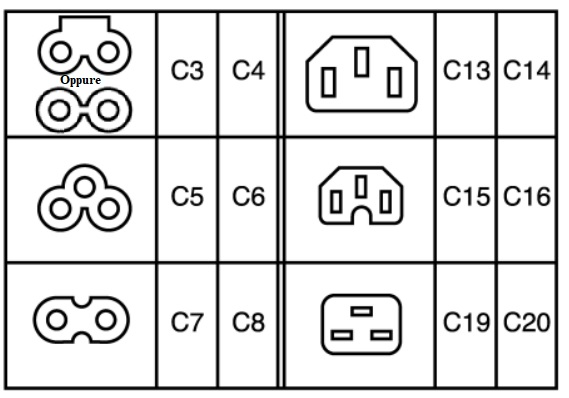

IEC 60320

Approximately 75% of all electronic devices worldwide utilize IEC 60320 connectors, underlining their universal adoption and essential role in the global electronics industry. IEC 60320 is a set of standards specifying non-locking appliance and interconnection couplers for connecting power supply cords to electrical appliances up to 250 volts.

- IEC 60320 connectors are classified into types according to their design, pin configuration, maximum current, and temperature rating.

- The most common types include C1/C2 (used for shavers), C5/C6 (used for laptop power bricks), and C13/C14 (used for desktop computers and monitors).

- Each type has specific safety features including polarisation, grounding connection, and protection against accidental contact with live parts.

- Variations exist within each connector type to cater to different regional wiring practices, voltage requirements, or equipment needs.

IEC 60309

Shifting focus to the realm of industrial applications, IEC 60309 represents a globally recognized standard for robust and safe electrical connectors.

This standard specifically outlines requirements for industrial-type plugs, socket-outlets and couplers intended for both indoor and outdoor use.

The distinction of these connectors lies in their ability to function under challenging environmental conditions such as high temperatures or exposure to chemicals.

One outstanding feature is the color-coded system indicating voltage and frequency, which enhances safety by preventing incompatible connections.

Furthermore, IEC 60309 connectors are designed with grounding contacts that engage before power contacts ensuring a secure connection before electricity flow begins.

These aspects contribute towards making them an indispensable part of operations in industries like construction, manufacturing, and event production where high levels of electrical power are required.

IEC 60309-2

Delving deeper into the domain of industrial electrical outlets, a noteworthy subcategory under scrutiny is 60309-2. As a subset of IEC 60309, it outlines specific regulations for plugs and socket-outlets for industrial purposes. These guidelines detail particular configurations to maintain safety and reliability in demanding environments.

The standard defines specifications for industrial grade connectors with IP44/IP67 ratings. It delineates color codes that correspond to different voltage and frequency combinations. It stipulates stringent requirements related to mechanical operation, ensuring durability. The standard prescribes strict temperature resistance parameters, catering to high-demand applications. It also provides details about the necessary tests and markings on these connectors.

Comprehending IEC 60309-2 aids in grasping the robust nature of female IEC connectors used in various industrial settings.

IEC 60309-4

Transitioning to the next segment, IEC 60309-4 emerges as a significant standard in the realm of industrial electrical outlets. This particular standard sets forth guidelines pertaining to switched socket-outlets and connector accessories for industrial purposes.

The key focus of this standard is on providing safety measures against electric shock and thermal effects. It also emphasizes ensuring compatibility between plugs and their corresponding sockets, thereby facilitating efficient power transmission.

In addition, IEC 60309-4 provides extensive details about testing methods for verifying the durability and reliability of female connectors under various operational conditions. Moreover, it offers detailed specifications regarding dimensions, functionality parameters, and design aspects to ensure user safety and performance efficiency.

Thus, IEC 60309-4 plays an instrumental role in shaping the quality standards for female IEC connectors in the industry.

Safety Considerations

In discussing safety considerations pertaining to female IEC connectors, three crucial elements emerge as significant.

First, the importance of proper handling and installation cannot be overstated, as it directly impacts the functionality and durability of these connectors.

Second, adherence to electrical safety regulations and standards is essential in ensuring secure operations while minimizing potential hazards.

Lastly, being cognizant of potential risks and taking necessary precautions contributes significantly towards maintaining a safe working environment and mitigating possible connector-related accidents.

Proper handling and installation

Navigating the realm of proper handling and installation of female IEC connectors can seem akin to deciphering an intricate puzzle, yet with comprehensive knowledge, it transforms into a straightforward task.

The first step is inspection; ensuring that the connector is free from any physical damage or irregularities that could impede functionality.

Secondly, the application of appropriate tools plays a crucial role. Using non-conductive tools mitigates risks associated with electrical shock during installation.

For secure connections, alignment must be accurate and firm pressure applied to engage the connector properly.

Finally, periodic checks post-installation are equally important to maintain optimal performance and safety standards.

By adhering to these fundamental practices, potential hazards associated with improper handling can be effectively mitigated while maximizing efficiency in operation.

Electrical safety regulations and standards

Adherence to electrical safety regulations and standards is paramount in ensuring the wellbeing of individuals and integrity of equipment involved. This dictates stringent requirements for installation, operation, and maintenance procedures.

The International Electrotechnical Commission (IEC) provides these standards for female IEC connectors, which are integral components in numerous electrical systems. Compliance with such standards ensures connector longevity and system reliability while mitigating risks associated with electrical faults.

Specific guidelines encompassing aspects such as voltage rating, current carrying capacity, insulation resistance among others need diligent observation. Additionally, regulatory norms mandate periodic inspections to confirm ongoing adherence.

Adopting a proactive approach towards compliance can significantly reduce potential hazards related to improper use or substandard connectors. This approach safeguards both human life and expensive hardware infrastructure.

Potential risks and precautions

Electricity, when mishandled, can indeed be a double-edged sword, posing substantial risks that warrant utmost caution and preventative measures. Especially with female IEC connectors, failure to adhere strictly to safety regulations can lead to electrocution, fire outbreaks, or equipment damage.

- Electrocution: The first potential risk involves the possibility of an electric shock resulting from direct contact with live parts of the connector not properly insulated or shielded. This could potentially lead to severe injuries or fatalities.

- Fire Outbreaks: Secondly, incorrect handling or faulty wiring can cause overheating and subsequent fires. Such incidences pose significant threats not only to individuals but also property.

- Equipment Damage: Lastly, inadequate understanding and misuse of female IEC connectors may result in irreparable harm to devices they are connected with due to power surges or short circuits.

Tips for Choosing the Right Female IEC Connector

When selecting the appropriate female IEC connector, there are several critical factors to consider.

Understanding power requirements (8.1) and ensuring compatibility with particular devices (8.2) forms an essential part of the selection process.

Environmental considerations (8.3), such as working temperature range and resistance to moisture, along with quality and reliability factors (8.4), including durability and performance under stress, also play a significant role in determining the suitability of a connector for specific applications.

Understanding power requirements

Grasping the power requirements of female IEC connectors is imperative for ensuring optimum performance and safety in electronic devices, stirring a sense of confidence and security in their usage. Understanding these requirements helps ascertain the compatibility between various devices and reduces potential risks related to overheating or electrical failure.

- Voltage Rating: This represents the maximum voltage that can be safely applied to an IEC connector; exceeding this limit may lead to a breakdown.

- Current Capacity: Denotes the maximum current that a connector can carry without causing damage due to excessive heating or other adverse conditions.

- Power Consumption: This refers to the amount of electric power consumed by an IEC connector under normal operating conditions, which is essential for energy efficiency calculations.

Checking compatibility with devices

Ensuring the compatibility of various electrical devices with their corresponding power sources constitutes a significant aspect of maintaining operational efficiency and safety. To this end, female IEC connectors are often utilised due to their universal design and broad applicability. These connectors have been standardized by the International Electrotechnical Commission (IEC) which ensures that they can be employed across a diverse range of electronic devices.

However, despite this standardization, not all IEC connectors are compatible with every device. Factors such as the shape and size of the connector, as well as the power requirements of the specific device need consideration. Therefore, it is imperative to carefully examine these factors before employing an IEC connector to ensure optimal performance and prevent potential damage to electronic equipment.

Considering environmental factors

Taking into account environmental factors is an integral part of maintaining electrical devices, as these conditions can significantly impact the functionality and longevity of the equipment. For female IEC connectors, various environmental elements play a vital role.

Factors such as temperature variations, humidity levels, dust accumulation, and chemical exposure can degrade the performance of these connectors over time. High temperatures can cause material distortion leading to loose connections while increased humidity levels may lead to corrosion that affects conductivity. Dust buildup might encroach on the contact points causing poor connection while exposure to certain chemicals could damage the material construction of these connectors.

It is therefore essential to consider appropriate protective measures for female IEC connectors under harsh environmental conditions to ensure their optimal functioning and extended lifespan.

Quality and reliability factors

Quality and reliability factors, such as material durability, design precision, and manufacturing standards, significantly contribute to the performance and longevity of electrical devices. These elements are particularly crucial in female IEC connectors given their vital role in power transmission. High-quality materials ensure robustness against wear and tear while precise design guarantees optimal alignment for secure connections. Furthermore, adherence to rigorous manufacturing standards ensures consistency in production quality.

In assessing these factors, it can be beneficial to consider the following:

| Factor | Consideration | Impact |

|---|---|---|

| Material Durability | Type of metal used; resistance features | Longevity; Resistance to corrosion |

| Design Precision | Alignment accuracy; Fitment with male connectors | Secure connection; Minimized risk of disconnection |

| Manufacturing Standards | Compliance with industry regulations | Consistency in quality; Safety assurance |

Through careful evaluation of these elements, one can ensure the selection of reliable female IEC connectors.

Installation and Maintenance

Transitioning from the selection process, this section delves into the practical aspects of female IEC connectors which include their installation, maintenance, and troubleshooting.

An elucidation on a step-by-step guide for installing these connectors will be provided alongside tips on proper storage and handling practices to ensure optimal performance and longevity.

Furthermore, an examination of cleaning and inspection procedures, repair and replacement guidelines as well as common issues that may arise during usage with proposed solutions form a part of this comprehensive discussion.

Step-by-step guide for installing a female IEC connector

Understanding the process of installing a female IEC connector can significantly enhance one’s proficiency in handling electrical components. This procedure includes preparation, connection, and testing phases.

The three-phase installation process is outlined below:

| Phase | Step | Description |

|---|---|---|

| Preparation | 1 | Acquire necessary tools such as wire strippers, screwdrivers, and the female IEC connector. |

| 2 | Turn off all power sources to avoid electric shock. | |

| Connection | 3 | Strip the wires and insert them into their respective terminals (Live – L, Neutral – N). Secure with screws. |

| 4 | Fit the casing over the secured wires and connector. Tighten accordingly. | |

| Testing | 5 | After reestablishing power supply, use a multimeter to confirm correct voltage across L and N terminals. |

This concise guide provides easy-to-follow steps for successful installation of a female IEC connector.

Storage and handling recommendations

Proper storage and handling of electrical components is crucial for maintaining their functionality and longevity. Female IEC connectors, like all electronic parts, should be stored in controlled environments to mitigate the risk of damage due to humidity, temperature fluctuations, and dust. Containers with anti-static properties are preferable for storage as they prevent static electricity build-up which can degrade the connector’s performance.

Moreover, during handling, use of ESD-protected gloves is beneficial in preventing electrostatic discharges that can affect the connector’s integrity. Regular inspection should also be carried out to identify any signs of corrosion or physical damage.

Furthermore, while transporting these connectors, cushioned packaging materials can minimize potential impacts caused by vibrations or shocks. These practices ensure optimal functioning and extended lifespan for female IEC connectors.

Cleaning and inspection

In the realm of electronic component maintenance, meticulous cleaning and inspection processes are vital to ascertain their operational efficiency and integrity. This is particularly applicable to female IEC connectors, which connect an array of electrical appliances to mains electricity supply.

These components should be routinely cleaned using a soft cloth or brush to remove dust particles that can impede function. A magnifying glass may aid in inspecting for any physical damage such as cracks, deformation or corrosion on the metal contacts.

Multimeters can also be employed to check for electrical continuity, ensuring there are no breaks in the circuitry that could disrupt power flow.

It is noteworthy that all cleaning and inspection procedures should be conducted with safety precautions, including disconnecting any power source prior to commencement.

Repair and replacement guidelines

Continuing from the meticulous practice of cleaning and inspecting female IEC connectors, it is crucial to understand that despite efficient maintenance, a situation may arise when repair or replacement becomes inevitable. This segment will delve into the guidelines for repairing and replacing these connectors.

| Steps | Repair | Replacement |

|---|---|---|

| 1 | Identify faulty parts | Determine if replacement is necessary |

| 2 | Use appropriate tools for repair work | Order exact match of connector model |

| 3 | Test connector post-repair for functionality | Remove old connector carefully |

| 4 | Ensure no damage has occurred during repair process | Install new connector properly |

| 5 | Implement preventive measures to avoid future damages | Test newly installed connector for functionality |

By following these steps diligently, one can ensure an extended lifespan and optimal performance of their female IEC connectors.

Troubleshooting common issues and solutions

Navigating through the realm of common issues and their respective solutions is a critical aspect of managing electrical connections, as it significantly augments system efficiency and longevity. When dealing with female IEC connectors, several prevalent problems may occur that require adept troubleshooting skills.

- Intermittent Disconnections: Such could be due to a loose connection or damaged wire within the connector.

- Overheating: This arises from excessive current flow or poor ventilation around the connector area.

- Corrosion: It results from exposure to moisture or harsh conditions which degrade the quality of the metal contact points.

- Physical Damage: This includes cracked housing or bent pins, often arising from improper handling.

Addressing these issues promptly ensures optimal performance of electronic devices reliant on female IEC connectors.

Frequently Asked Questions (FAQs)

What are the main differences between a female IEC connector and a male IEC connector?

Distinguishing between a female IEC connector and a male one primarily hinges on their structural design and the roles they play in establishing an electrical connection.

The primary difference lies in the physical structure, where the female connector is designed to receive or ‘accept’ the male connector. Female connectors possess receptacles that correspond with pins found on male connectors.

In contrast, a male IEC connector features protruding pins that insert into matching slots of the female counterpart. This arrangement facilitates safe and secure electric current transmission from one device to another.

Further distinction can be observed in usage scenarios; female connectors are typically implemented on appliances while male connectors are often found on power cords or cables.

Therefore, understanding these differences contributes significantly to effective utilization of IEC connectors.

Can a female IEC connector be used with different voltage ratings?

Voltage compatibility is a crucial factor when considering the use of any electrical connector, and this rule applies universally across different types. For instance, imagine a scenario akin to trying to fit a square peg into a round hole; attempting to force incompatible voltage ratings can result in unsafe conditions and potential damage to equipment.

Female IEC connectors are no exception, as they must match with their corresponding male counterparts in terms of voltage rating for safe operation. To exemplify, consider the table below:

| Female IEC Connector | Voltage Rating |

|---|---|

| C13 | 250V |

| C19 | 250V |

| C15 | 250V |

| C21 | 250V |

This illustrates how different female IEC connectors have similar voltage ratings.

How do I determine the correct amperage rating for a female IEC connector?

Establishing the correct amperage rating for an electrical connector is pivotal and involves consideration of various factors such as equipment specifications, safety standards, and overall power requirements.

The amperage rating represents the maximum current that a female IEC connector can carry safely without overheating or causing any potential damage to the attached device.

- Equipment Specifications: The device connected to the female IEC connector will have its own specific current requirements. It is crucial not to exceed these specifications.

- Safety Standards: Overloading an electrical circuit can lead to severe consequences including fires. Adhering strictly to safety standards ensures minimal risk.

- Overall Power Requirements: Calculating total power needs helps in determining the adequate amperage for a system, preventing overloads or underperformance due to insufficient power supply.

Are female IEC connectors interchangeable across different countries?

Despite the universal design of these power interfaces, the interchangeability across different countries is not always guaranteed due to variances in voltage standards and plug types.

For instance, a device purchased in Europe may be equipped with a Type C plug, which cannot directly interface with the Type A outlets commonly found in North America, necessitating the use of an adapter or converter for proper functionality.

Moreover, voltage levels differ globally: North America operates at 110-120V while Europe uses 220-240V. Thus, even if physical compatibility is achieved through an adapter, electrical compatibility must also be ensured to avoid damage to equipment.

Consequently, it’s critical to consider both plug type and voltage requirements when utilizing female IEC connectors internationally.

Conclusion

In conclusion, this comprehensive guide has elucidated numerous aspects of female IEC connectors, spanning from their fundamental characteristics to extensive applications.

Their pervasive influence in various industries cannot be underestimated due to their vital contributions towards ensuring efficient power supply, transmission and conversion.

It is thus apparent that a deeper comprehension of these components, coupled with prudent selection and utilization can significantly boost system performance and reliability.

Key points discussed in the blog post

Reflecting on the key points discussed throughout this comprehensive guide, it becomes clear that female IEC connectors play an indispensable role in various technological applications. The importance of these components cannot be overstated as they function as fundamental elements in electrical and electronic equipment.

- International Standards: Female IEC connectors are designed and manufactured according to international standards, ensuring consistency and reliability across varying applications.

- Safety Measures: These connectors incorporate robust safety features to protect against potential hazards such as electric shock.

- Variety of Models: They come in a wide range of types and sizes, each with specific attributes catering to different power needs and usage scenarios.

- Global Acceptance: Owing to their standardized design, these connectors are widely accepted globally, which simplifies international trade of electronic devices.

Importance of female IEC connectors in various industries

As the linchpin in various industries, these integral components serve as bridges to transfer electrical power efficiently and safely, symbolizing how critical elements can facilitate seamless operations in technological applications. Female IEC connectors are pivotal in sectors like telecommunications, computer networking, broadcasting, and medical instrumentation.

Their importance is undeniable due to their role in ensuring safe electrical connections. The need for standardization across industries calls for a versatile component such as the female IEC connector that contributes towards uniformity of equipment design and compatibility.

| Industry | Application of Female IEC Connectors | Benefits |

|---|---|---|

| Telecommunications | Power delivery within network systems | Enhanced system reliability |

| Computer Networking | Connection between power supply units & devices | Reduced risk of connection failures |

| Broadcasting | Linking audio-visual devices to power outlets | Ensured safety against electrical faults |

| Medical Instrumentation | Facilitate operation of medical devices | Improved device performance |

These instances underline the necessity and widespread usage of female IEC connectors across diverse industries.

Final thoughts and recommendations

Having explored the significance of female IEC connectors in various sectors, it becomes paramount to conclude with some final thoughts and recommendations.

- Quality Assurance: Given their widespread use across industries such as telecommunications, medical technology, and broadcasting services, it is crucial to prioritize high-quality female IEC connectors. Substandard products could lead to poor performance and potential safety risks.

- Compatibility: Ensure that the said connectors are compatible with the devices they are intended for. Incompatibility can cause inefficiencies and potential damage.

- Supplier reliability: Lastly, consideration should be given to the supplier’s reputation. A dependable supplier guarantees quality products, timely delivery and offers essential after-sales support services.

These three points form a holistic approach towards effective utilization of female IEC connectors in various applications.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd