What is DC Switch?

A DC switch is an electrical device designed to interrupt the flow of direct current (DC) in a circuit. Unlike alternating current (AC) switches, which manage current that changes direction periodically, DC switches handle current that flows in a single, unidirectional path. This unique characteristic of DC current presents specific challenges and requirements for switches designed to manage it.

DC switches are essential components in various applications, including automotive systems, renewable energy installations, industrial machinery, and consumer electronics. Their ability to safely and effectively control DC current makes them indispensable in environments where DC power is prevalent.

Importance and Applications of DC Switches

DC switches are devices used to control the flow of direct current (DC) in electrical circuits. They are essential for safely turning DC circuits on and off, isolating parts of a circuit for maintenance, and protecting against overcurrent and short circuits. DC switches are found in various applications, including renewable energy systems like solar panels, electric vehicles, power distribution networks, and industrial automation.

Their importance lies in their ability to handle high current loads and voltages typical in DC circuits, ensuring efficient and safe operation. They also help in improving system reliability, facilitating maintenance, and enhancing overall safety.

How Does a DC Switch Work?

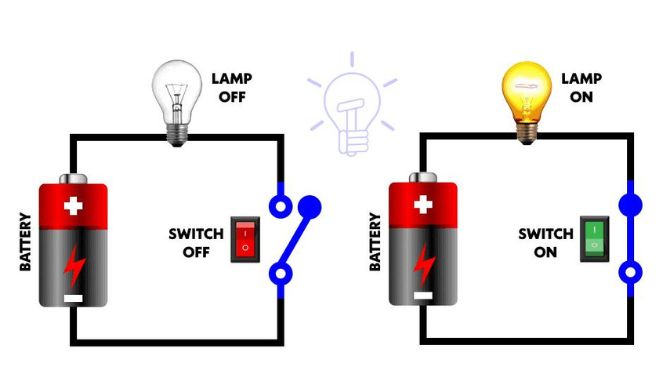

A DC switch operates by creating a physical break in the electrical circuit, interrupting the flow of direct current (DC). This interruption can be temporary, such as when a button is pressed, or permanent until the switch is manually reset or toggled. The key difference between DC and AC (alternating current) switches lies in how they handle the current flow. DC flows continuously in one direction, which means that when a DC circuit is broken, an arc can form and be sustained across the switch contacts. This arc must be quenched quickly to prevent damage or fire hazards.

Basic Working Principle

- Contact Mechanism: DC switches typically use robust contact mechanisms to ensure a quick and clean break in the circuit. This minimizes the chances of arcing.

- Arc Suppression: Many DC switches incorporate arc suppression techniques, such as magnetic blowouts or arc chutes, to dissipate the energy and extinguish the arc.

- Actuation Methods: DC switches can be actuated through various methods, including toggles, push-buttons, rotary mechanisms, and automated systems.

Common Voltage and Current Ratings for DC Switches

| Voltage Rating | Typical Applications | Current Rating | Typical Applications |

|---|---|---|---|

| 12V | Automotive, small electronics | 10A | Automotive, small appliances |

| 24V | Industrial control systems | 20A | Industrial machinery, HVAC systems |

| 48V | Renewable energy systems | 50A | Electric vehicles, power distribution |

| 100V+ | Specialized industrial applications | 100A+ | High-power applications, large-scale systems |

Applications of DC Switches by Industry

| Industry | Applications | Key Requirements |

|---|---|---|

| Automotive | EV power management, lighting, ignition systems | Durability, reliability, compact design |

| Renewable Energy | Solar panel isolation, wind turbine control | High voltage/current rating, safety |

| Industrial | Control panels, automation systems | Robustness, precise control, long lifespan |

| Consumer Electronics | Small appliances, portable devices | Compact size, user-friendly, reliable |

| Medical | Ventilators, diagnostic machines | High precision, safety standards |

| Aerospace & Defense | Aircraft controls, satellite power management | High durability, specialized design |

| Marine | Navigation systems, lighting controls | Corrosion resistance, reliable operation |

DC VS AC

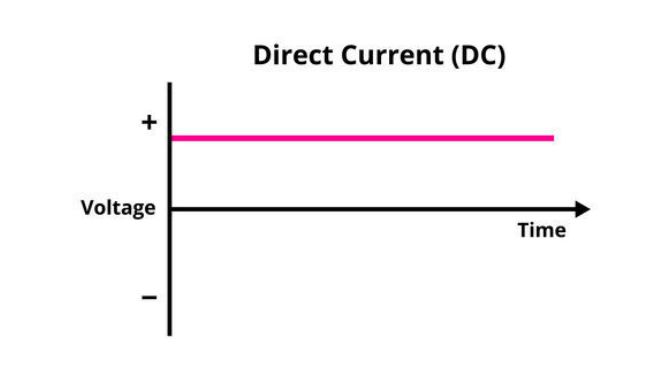

In DC, the electric charge flows in one direction. It’s used in batteries, solar panels, and electronic devices. DC is stable and efficient for low-voltage applications.

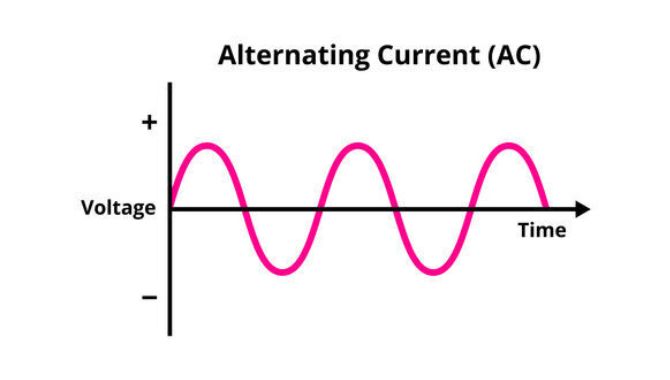

In AC, the electric charge periodically reverses direction. It’s the standard form of electricity supplied to homes and businesses. AC is more efficient for transmitting power over long distances due to its ability to easily transform voltages with transformers.

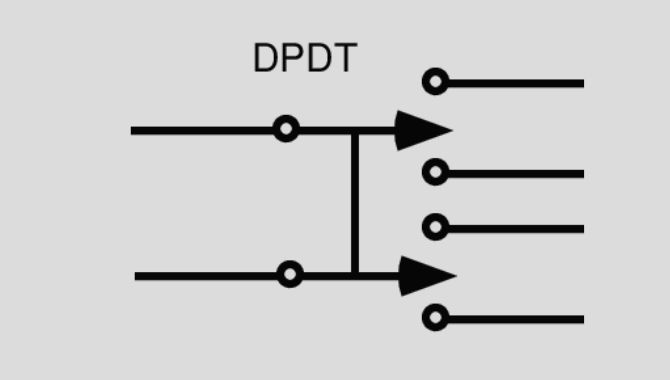

Types of DC Switches

DC rocker switches are electrical switches used to control the flow of direct current (DC) in a circuit. They feature a rocking mechanism that moves back and forth, toggling the circuit between on and off positions. These switches are commonly used in various applications, such as automotive, marine, and industrial equipment, due to their durability and ease of use.

A DC Marine Rocker Switch is an electrical switch commonly used in marine applications to control various onboard systems, such as lighting, pumps, or other equipment. It is designed to withstand harsh marine environments, featuring a durable, waterproof construction. The switch operates by rocking back and forth to open or close a circuit, allowing for easy operation even in challenging conditions.

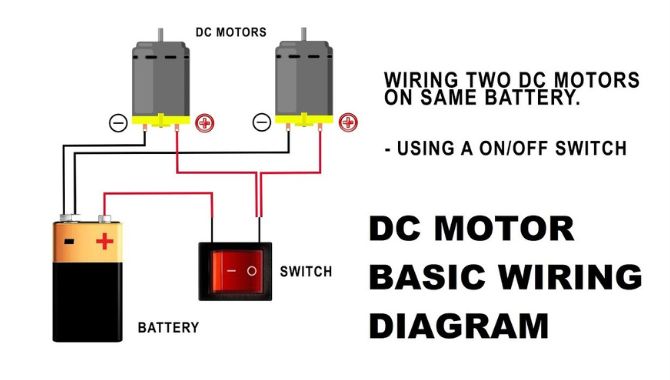

A DC toggle switch is an electrical device used to control the flow of direct current (DC) in a circuit. It has a lever or handle that can be flipped to open or close the circuit, allowing or interrupting the current flow. Commonly used in various applications, including electronics, automotive, and industrial systems, it provides a simple and reliable way to manage power.

A DC micro switch is a small, often snap-action switch used in electronic devices to open or close a circuit. It operates with direct current (DC) and is known for its quick response and high durability. Common applications include automotive, industrial equipment, and consumer electronics, where precise and reliable switching is essential. Its compact size makes it ideal for space-constrained environments.

A DC push button switch is an electrical component used to control the flow of direct current (DC) in a circuit. It operates by pressing a button to open or close the circuit, enabling or disabling the current flow. These switches are commonly found in various electronic devices and applications where momentary or maintained contact is required to start, stop, or reset functions.

FAQs

DC Switch are commonly used in various applications, and people often have questions about them. Here are five of the most popular FAQs for DC Switch

DC switches are designed to handle the continuous flow of direct current, which can produce more arcing than alternating current (AC) when interrupted. Therefore, DC switches often have more robust contacts and arc-extinguishing mechanisms compared to AC switches.

- Solar Power Systems: Disconnecting solar panels from the grid.

- Electric Vehicles: Controlling power between the battery and the motor.

- Industrial Equipment: Managing power in machinery and tools that operate on DC.

- Battery Systems: Isolating batteries for maintenance and safety.

- Voltage and Current Rating: Ensure the switch can handle the specific voltage and current of your application.

- Contact Material: Suitable for DC applications to reduce arcing.

- Durability: Robust construction for longevity and reliability.

- Safety Certifications: Compliance with industry standards and regulations.

Yes, DC switches are available for both low and high voltage applications. It’s important to select a switch rated appropriately for your specific voltage and current requirements.

- Proper Rating: Use switches rated for your application’s voltage and current.

- Insulation: Ensure proper insulation to prevent short circuits and shocks.

- Regular Maintenance: Periodically check and maintain switches to ensure they function correctly.

- Professional Installation: Have qualified personnel install and inspect the switches.

- Efficient Control: Precise control over DC circuits.

- Safety: Designed to handle high current and voltage safely.

- Durability: Built to withstand the harsh conditions often found in DC applications.

- Turn off Power: Ensure all power sources are turned off before installation.

- Follow Instructions: Adhere to the manufacturer’s installation guide.

- Secure Connections: Make sure all connections are secure and insulated.

- Test: Test the switch to ensure proper operation after installation.

- Regular Inspections: Check for wear, corrosion, and proper operation.

- Clean Contacts: Clean contacts to ensure good conductivity.

- Tighten Connections: Ensure all connections remain tight and secure.