In the world of electronics, appliances, and power tools, the humble switch plays a critical role in functionality, safety, and user experience. Among the various switch types, maintained switches stand out for their unique operational characteristics and versatility across multiple applications. This comprehensive guide explores everything procurement professionals in the electronics, appliance, and power tool industries need to know about maintained switches, with a special focus on WEUP’s superior maintained switch solutions.

What is a Maintained Switch? Definition and Basic Concepts

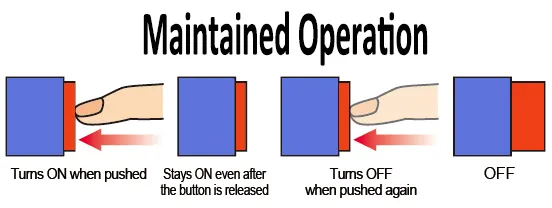

A maintained switch is a type of electrical switch that retains its position after actuation until it is actuated again. Unlike momentary switches that return to their original position once released, maintained switches “remember” their state, making them ideal for applications requiring consistent power supply or operational states without continuous user interaction.

The Fundamental Difference Between Maintained and Momentary Switches

The primary distinction between maintained and momentary switches lies in their operational behavior:

Maintained switches change position when actuated and remain in that position until actuated again. The classic example is a standard light switch in your home – flip it on, and it stays on until you flip it off. This “memory” feature makes maintained switches perfect for controlling functions that need to remain in a specific state for extended periods.

Momentary switches, conversely, are only actuated while being pressed or held. A doorbell button exemplifies this functionality – the circuit closes only while you’re pressing the button. Once released, the switch automatically returns to its default position.

This fundamental difference determines which switch type is appropriate for specific applications. Maintained switches excel in scenarios where consistent states are required without continuous user interaction, while momentary switches are better suited for temporary actions or safety-critical applications where automatic return to a default state is necessary.

Key Components of a Maintained Switch

Understanding the anatomy of a maintained switch helps in appreciating its functionality and durability:

Actuator: The external part that users interact with, such as a lever, rocker, or button. The actuator’s design significantly impacts user experience and suitability for different environments.

Contacts: The internal metal components that either connect or disconnect to complete or break the electrical circuit. The quality of these contacts directly affects the switch’s reliability and lifespan.

Housing: The protective casing that contains the internal components and provides structural support. Housing materials vary based on application requirements, from basic plastics for consumer electronics to ruggedized metals for industrial equipment.

Mounting Mechanism: The components that secure the switch to the device or panel. Different mounting options accommodate various installation requirements and space constraints.

Terminal Connections: The points where external wiring connects to the switch. These may vary in design based on current ratings and application needs.

How Maintained Switches Work: Operating Principles

The operation of maintained switches relies on mechanical principles that enable their state-retention capability, a feature that distinguishes them from other switch types.

The Mechanics Behind Maintained Switch Operation

Maintained switches employ various mechanisms to retain their position after actuation:

Detent Mechanism: Many maintained switches use a detent system – a mechanical arrangement that uses spring tension against a shaped surface to hold the switch in position. When sufficient force is applied to the actuator, it overcomes this tension and moves to a new position, where it’s then held by the same mechanism.

Latching Mechanism: Some maintained switches utilize a latching system where moving parts physically lock into position until released by subsequent actuation. This provides a definitive tactile feedback and ensures the switch remains in position even under vibration or minor disturbances.

Magnetic Retention: Advanced maintained switches may employ magnetic forces to hold the switch position, offering smooth operation with minimal mechanical wear.

The specific mechanism employed affects the switch’s feel, durability, and suitability for different operating environments. For instance, switches designed for high-vibration environments typically feature stronger retention mechanisms to prevent accidental state changes.

Electrical Circuit Integration

From an electrical perspective, maintained switches function as controllable gates in a circuit:

In the ON position, the switch’s contacts connect, allowing current to flow through the circuit and powering the connected device or function. In the OFF position, the contacts separate, breaking the circuit and stopping current flow.

This simple but effective functionality makes maintained switches ideal for controlling power to devices, selecting between operational modes, or enabling/disabling specific functions within a system.

The electrical characteristics of maintained switches – including current rating, voltage capacity, and contact resistance – are critical specifications that determine their suitability for specific applications. WEUP maintained switches are engineered with premium-grade contacts that ensure reliable performance even in high-cycle applications, minimizing contact resistance and heat generation.

Types of Maintained Switches: Comprehensive Classification

Maintained switches come in various forms, each designed to meet specific operational requirements and environmental conditions.

Toggle Maintained Switches: Features and Characteristics

Toggle maintained switches feature a lever or “bat” that moves between positions. These switches are among the most recognizable and widely used maintained switch types.

Key Characteristics:

- Compact Footprint: Toggle switches typically require minimal panel space, making them ideal for applications with space constraints.

- Excellent Durability: With their robust construction and often metal housings, toggle switches withstand harsh conditions and frequent use.

- Easy Sealing: Toggle switches can be effectively sealed with boot covers, enhancing their suitability for outdoor or industrial environments where moisture and dust protection is essential.

- Tactile Feedback: The distinct movement and position of the toggle lever provides clear visual and tactile indication of the switch state.

Common Applications: Toggle maintained switches excel in industrial control panels, military equipment, aviation systems, and heavy machinery where reliability and clear state indication are paramount.

Size Classifications: Toggle switches typically come in three size categories:

- Sub-Mini: Compact switches for space-constrained applications, typically rated for 3A at 125VAC or 1.5A at 250VAC.

- Miniature: Medium-sized switches offering a balance between size and functionality, usually rated for 6A at 125VAC or 3A at 250VAC.

- Standard/Medium: Larger switches for applications requiring higher current handling or where robust operation with gloved hands is necessary.

Rocker Maintained Switches: Design and Functionality

Rocker switches feature a seesaw-like actuator that rocks between positions, offering a different aesthetic and operational experience compared to toggle switches.

Key Characteristics:

- Customizable Face: Rocker switches often feature a larger surface area that can accommodate custom icons or text to indicate function.

- Backlighting Options: Many rocker switches can incorporate backlighting to indicate status or improve visibility in low-light conditions.

- Ergonomic Operation: The rocking motion requires minimal force and is intuitive for users, making these switches popular in consumer applications.

- Aesthetic Appeal: Rocker switches often offer a more modern, streamlined appearance compared to toggle switches.

Common Applications: Rocker maintained switches are frequently used in consumer electronics, household appliances, automotive interiors, and control panels where user interface aesthetics are important.

Design Variations: Rocker switches come in various shapes and sizes, from small rectangular switches for electronics to large, illuminated rockers for appliances and industrial equipment.

Other Maintained Switch Variants

Beyond the common toggle and rocker types, several other maintained switch variants serve specialized applications:

Rotary Maintained Switches: These switches rotate between multiple positions and maintain their setting until turned again. They’re ideal for selecting between multiple options or modes and are common in appliances, HVAC controls, and industrial equipment.

Slide Maintained Switches: Featuring a linear sliding action, these switches maintain position and are often used in consumer electronics where a low profile is desired.

Push-Push Maintained Switches: These switches alternate between ON and OFF states with successive pushes, combining the tactile feel of a momentary switch with the state retention of a maintained switch.

Key-Operated Maintained Switches: Requiring a key for operation, these switches add a security dimension to the maintained functionality, preventing unauthorized state changes.

WEUP offers an extensive range of maintained switch variants, each engineered to exacting standards for specific application requirements in the electronics, appliance, and power tool industries.

Applications of Maintained Switches in Various Industries

The versatility of maintained switches makes them indispensable across numerous industries and applications, particularly in the sectors served by WEUP.

Electronic Devices and Small Appliances

In consumer and professional electronic devices, maintained switches serve critical functions:

Power Control: The most fundamental application is controlling the main power to devices. Maintained switches ensure devices remain in their desired power state without requiring continuous user interaction.

Mode Selection: Many electronic devices offer multiple operational modes, with maintained switches providing an intuitive interface for selecting and maintaining the desired mode.

Function Enabling/Disabling: Features like Wi-Fi, Bluetooth, or specific processing modes in electronic devices often utilize maintained switches for persistent state control.

WEUP’s maintained switches for electronic applications are designed with low profile options, smooth actuation force, and long cycle life to meet the demands of modern electronic devices while maintaining excellent tactile feedback.

Power Tools and Equipment

Power tools represent one of the most demanding applications for maintained switches, requiring durability and reliability under challenging conditions:

Safety Lockouts: Maintained switches often serve as safety mechanisms in power tools, requiring deliberate actuation to enable operation and preventing accidental activation.

Operational Mode Selection: Many power tools offer multiple speed settings or operational modes controlled by maintained switches that must retain their position even under vibration.

Battery Disconnect: In battery-powered tools, maintained switches may control the connection between the battery and the tool’s circuitry.

WEUP’s maintained switches for power tool applications feature reinforced housings, vibration-resistant mechanisms, and dust/moisture protection to ensure reliable operation in construction sites, workshops, and manufacturing environments.

Industrial Machinery and Control Systems

Industrial applications demand the highest levels of reliability and durability from maintained switches:

Control Panel Interfaces: Industrial control panels utilize maintained switches for consistent control of processes, equipment states, and operational modes.

Emergency Stop Override: While emergency stops typically use momentary switches, their reset mechanisms often employ maintained switches to ensure deliberate reactivation.

System Configuration: Many industrial systems require configuration settings that must persist through power cycles, making maintained switches ideal for these applications.

WEUP’s industrial-grade maintained switches are engineered to withstand extreme temperatures, chemical exposure, high humidity, and continuous operation in demanding industrial environments.

Household Electrical Applications

In household applications, maintained switches blend functionality with user-friendly design:

Lighting Control: The classic application of maintained switches in homes is controlling lighting fixtures, where the switch state directly corresponds to the light state.

Appliance Operation: From toasters to fans, household appliances rely on maintained switches for intuitive user control and consistent operation.

HVAC Systems: Climate control systems often use maintained switches for mode selection and system enabling/disabling.

WEUP’s household application switches combine reliability with aesthetic appeal, offering options that complement modern interior design while providing the dependable performance expected in daily use.

Selecting the Right Maintained Switch: Factors to Consider

Choosing the appropriate maintained switch for a specific application involves evaluating several critical factors:

Technical Specifications and Ratings

Current and Voltage Ratings: Perhaps the most fundamental consideration is whether the switch can handle the electrical load of the application. Underrated switches may fail prematurely or pose safety hazards.

Contact Configuration: Maintained switches come in various contact arrangements:

- SPST (Single Pole, Single Throw): Controls a single circuit in on/off mode

- SPDT (Single Pole, Double Throw): Connects one input to either of two outputs

- DPST (Double Pole, Single Throw): Controls two independent circuits simultaneously

- DPDT (Double Pole, Double Throw): Controls two independent circuits, each with two possible connections

Actuation Force: The force required to change the switch state affects user experience and accessibility. Applications for elderly or disabled users may require switches with lower actuation force.

Cycle Life: The expected number of operations before failure is critical for applications with frequent switching. WEUP maintained switches are tested to exceed industry standards for operational lifespan.

Environmental Considerations

Temperature Range: Switches must function reliably within the temperature range of their operating environment. Extreme heat or cold can affect switch mechanics and electrical properties.

Moisture and Dust Protection: For applications exposed to environmental elements, IP (Ingress Protection) ratings indicate the switch’s resistance to dust and moisture.

Chemical Resistance: In environments where exposure to oils, solvents, or cleaning agents is likely, switch materials must resist degradation from these substances.

Vibration and Shock Resistance: Applications subject to mechanical stress require switches designed to maintain their state even under vibration or impact.

Durability and Lifespan Requirements

Material Quality: The durability of a maintained switch largely depends on the quality of its components. WEUP uses premium materials in all switch components, from contact metals to housing polymers.

Contact Design: Advanced contact designs minimize arcing and heat generation, extending switch lifespan and maintaining consistent performance.

Mechanical Robustness: The physical construction of the switch determines its resistance to mechanical wear and abuse.

Expected Usage Patterns: Applications with frequent switching require more durable switches than those switched infrequently.

Size and Mounting Constraints

Panel Space: Available space often dictates switch selection, particularly in compact devices or crowded control panels.

Mounting Method: Switches can be panel-mounted, PCB-mounted, or surface-mounted, each with different space and installation requirements.

Orientation Flexibility: Some applications may require switches that can be mounted in various orientations while maintaining proper functionality.

Accessibility Requirements: User accessibility considerations may influence switch size, position, and actuation method.

WEUP’s engineering team specializes in helping procurement professionals select the optimal maintained switch for specific applications, considering all relevant factors to ensure perfect fit and function.

WEUP Maintained Switches: Superior Quality for Your Applications

WEUP has established itself as a leading provider of high-quality maintained switches for the electronics, appliance, and power tool industries, offering solutions that combine reliability, performance, and value.

WEUP’s Innovative Maintained Switch Technology

WEUP’s commitment to innovation is evident in our maintained switch technology:

Enhanced Contact Systems: Our proprietary contact designs minimize resistance and heat generation while maximizing durability, resulting in switches that maintain consistent performance throughout their extended lifespan.

Advanced Materials: WEUP utilizes high-performance polymers and metals that exceed industry standards for durability, temperature resistance, and mechanical strength.

Precision Manufacturing: State-of-the-art production facilities and rigorous quality control ensure that every WEUP maintained switch meets exacting specifications for dimensional accuracy and operational consistency.

Ergonomic Design: Our switches are engineered with user experience in mind, offering intuitive operation and clear state indication while maintaining aesthetic appeal.

Product Range and Customization Options

WEUP offers an extensive range of maintained switches to meet diverse application requirements:

Toggle Maintained Switches: Available in sub-mini, miniature, and standard sizes with various actuator styles, current ratings, and mounting options.

Rocker Maintained Switches: From compact indicators to large power controls, with options for custom markings, illumination, and specialized actuation characteristics.

Specialized Variants: Including rotary selectors, keylock switches, and hybrid designs that combine maintained and momentary functions for specialized applications.

Customization Services: WEUP offers extensive customization options, including:

- Custom actuator designs and colors

- Specialized contact arrangements

- Modified operating characteristics

- Integrated LED indicators

- Custom terminal configurations

- Application-specific environmental sealing

Quality Assurance and Reliability

WEUP’s reputation for quality is built on comprehensive testing and validation:

Rigorous Testing: Every WEUP maintained switch design undergoes extensive testing for electrical performance, mechanical durability, and environmental resistance.

Accelerated Life Testing: Our switches are subjected to accelerated life cycle testing that simulates years of use in compressed timeframes, ensuring long-term reliability.

Environmental Simulation: WEUP tests switches under extreme conditions, including temperature cycling, humidity exposure, salt spray, and vibration testing.

Quality Certifications: Our manufacturing facilities maintain ISO 9001 certification, and our products comply with relevant industry standards including UL, CSA, and RoHS requirements.

Experience the WEUP Difference

Join the growing number of electronics, appliance, and power tool manufacturers who trust WEUP maintained switches for their critical applications. Our engineering team is ready to help you select or customize the perfect switch solution for your specific requirements.

Installation and Maintenance Best Practices

Proper installation and maintenance of maintained switches are essential for optimal performance and longevity.

Proper Installation Techniques

Mounting Considerations:

- Ensure adequate panel thickness and cutout dimensions per switch specifications

- Use appropriate mounting hardware, including lock washers for toggle switches to prevent rotation

- Maintain minimum clearances around switches for proper operation and heat dissipation

- Consider orientation relative to gravity and user access

Electrical Connection Best Practices:

- Use appropriately rated wire for the application’s current requirements

- Ensure secure terminal connections with proper torque

- Implement strain relief to prevent wire movement from affecting terminal connections

- Follow proper soldering techniques for PCB-mounted switches

Environmental Protection:

- Apply appropriate sealing methods for switches in moisture-prone environments

- Use protective boots or covers in dusty conditions

- Consider conformal coating for PCB-mounted switches in harsh environments

- Implement appropriate ingress protection based on the application environment

Maintenance Tips for Extended Lifespan

While WEUP maintained switches are designed for minimal maintenance, these practices can further extend their operational life:

Regular Inspection: Periodically check switches for signs of wear, loose mounting, or terminal connection issues.

Contact Cleaning: In accessible switches, contacts can occasionally be cleaned with appropriate electrical contact cleaners to remove oxidation or contamination.

Actuator Maintenance: For switches with mechanical actuators, ensure freedom of movement and lubricate if recommended by the manufacturer.

Environmental Protection: Maintain environmental seals and replace protective boots if they show signs of degradation.

Troubleshooting Common Issues

Even the best maintained switches may occasionally exhibit issues. Here’s how to address common problems:

Intermittent Operation: Often caused by loose connections or contact contamination. Check terminal connections and clean contacts if accessible.

Excessive Heat: May indicate the switch is underrated for the application or has developed high contact resistance. Verify current ratings and replace if necessary.

Mechanical Binding: If the switch doesn’t move freely, check for mechanical interference, damage to the actuator, or contamination in the mechanism.

Contact Welding: In high-current applications, contacts may occasionally weld together. This indicates the switch is underrated for the inrush current or load characteristics.

WEUP’s technical support team is available to assist with troubleshooting and provide application-specific guidance for maintaining optimal switch performance.

Comparing Maintained Switches with Alternative Solutions

Understanding how maintained switches compare to alternatives helps in making informed design and procurement decisions.

Maintained vs. Momentary: When to Use Each

Use Maintained Switches When:

- The function needs to remain in a specific state without continuous user interaction

- Visual indication of the current state is important

- The application involves selecting between operational modes that persist until changed

- Power control needs to be maintained through power cycles or system restarts

Use Momentary Switches When:

- The function should only be active during user interaction

- Safety considerations require automatic return to a default state

- The application involves triggering events rather than maintaining states

- The system uses electronic latching or software to maintain states

Hybrid Approaches: Some applications benefit from combining both switch types or using specialized switches that offer both maintained and momentary functionality in different actuation patterns.

Cost-Benefit Analysis for Different Applications

When evaluating maintained switches against alternatives, consider these factors:

Initial Cost vs. Lifetime Value: While premium maintained switches like those from WEUP may have higher initial costs, their extended lifespan and reliable performance often result in lower total ownership costs.

Mechanical vs. Electronic Solutions: Modern electronic interfaces (touch screens, capacitive sensors) may replace traditional switches in some applications, but maintained switches offer advantages in reliability, tactile feedback, and operation with gloves or in harsh environments.

Simplicity vs. Complexity: Maintained switches provide straightforward, intuitive control without requiring power or programming, making them ideal for applications where simplicity and reliability are paramount.

Regulatory Considerations: Some applications have regulatory requirements that specifically call for mechanical switching with positive indication of state, making maintained switches the necessary choice.

WEUP’s engineering team can assist in evaluating the optimal switching solution for specific applications, considering all relevant factors from performance requirements to total cost of ownership.

Future Trends in Maintained Switch Technology

While maintained switches represent mature technology, innovation continues in several areas:

Innovations in Materials and Design

Advanced Polymers: New polymer formulations offer improved temperature resistance, durability, and tactile characteristics while reducing weight and manufacturing costs.

Contact Materials: Developments in contact metallurgy and plating technologies are enhancing electrical performance and extending operational life even in challenging environments.

Miniaturization: Ongoing efforts to reduce switch size while maintaining or improving performance characteristics are enabling new applications in space-constrained devices.

Ergonomic Advancements: Research into human factors is driving improvements in switch feel, actuation force, and feedback mechanisms for enhanced user experience.

Smart Integration Possibilities

Hybrid Mechanical-Electronic Switches: Emerging designs combine the tactile reliability of mechanical maintained switches with electronic sensing and communication capabilities.

Status Monitoring: Integration of sensors that monitor switch position, temperature, and cycle count can enable predictive maintenance and system diagnostics.

IoT Connectivity: Switches with integrated communication capabilities can report state changes to networked systems, enabling remote monitoring and control.

Energy Harvesting: Advanced switches may incorporate energy harvesting from the mechanical actuation process to power integrated electronics without external power sources.

WEUP remains at the forefront of these technological developments, continuously incorporating proven innovations into our maintained switch product line while maintaining the reliability and durability our customers depend on.

How to Order WEUP Maintained Switches for Your Business

WEUP makes the procurement process straightforward and efficient, ensuring you get the right maintained switches for your specific requirements.

Procurement Process Simplified

Needs Assessment: Our process begins with understanding your application requirements, including electrical specifications, environmental conditions, space constraints, and user interface considerations.

Product Selection: Based on your requirements, our team will recommend standard products or suggest customization options to perfectly match your needs.

Sample Evaluation: For new applications or customers, we offer sample units for testing and evaluation in your specific environment.

Quotation and Ordering: Once the appropriate switch is identified, we provide competitive quotations with transparent pricing and lead times.

Production and Quality Assurance: All WEUP maintained switches undergo rigorous quality control throughout the production process, ensuring consistency and reliability.

Delivery and Support: We offer flexible shipping options and provide comprehensive post-sale support, including technical assistance and warranty service.

Custom Solutions and Support Services

Beyond our standard product range, WEUP offers extensive customization and support services:

Design Collaboration: Our engineering team can work directly with your designers to develop maintained switches tailored to your specific requirements.

Prototype Development: For unique applications, we offer rapid prototype development and iteration to perfect the switch design before full production.

Technical Documentation: We provide comprehensive technical documentation, including CAD files, specification sheets, and installation guidelines.

Compliance Support: Our team can assist with regulatory compliance requirements, providing necessary documentation and testing certifications.

Inventory Management: For regular customers, we offer inventory management programs to ensure consistent supply without excessive inventory costs.

Contact Information and Next Steps

Ready to Enhance Your Products with WEUP Maintained Switches?

Contact our dedicated sales and engineering team to discuss your maintained switch requirements:

- Email: [email protected]

- Phone: +86 13285879777

- Online: Complete our quick inquiry form on our website

Our team typically responds within 24 hours to all inquiries, and we’re ready to help you find the perfect maintained switch solution for your application.

WEUP is committed to being your trusted partner for maintained switches and other electrical components. With our combination of product quality, technical expertise, and customer service, we strive to exceed your expectations and contribute to the success of your products in the marketplace.

Discover why leading manufacturers in the electronics, appliance, and power tool industries choose WEUP maintained switches for their most demanding applications.