Technical Specifications and Selection Criteria for Push Button Switches

When procuring push button switches, understanding the technical specifications is crucial for ensuring compatibility, performance, and longevity. This section explores the key parameters that should guide your selection process.

Critical Electrical Parameters: Voltage, Current, and Contact Ratings

The electrical specifications of push button switches determine their compatibility with your system and their performance under load. Key parameters include:

Voltage Rating indicates the maximum voltage the switch can safely handle. Exceeding this rating can lead to arcing, contact damage, or insulation breakdown. Switches are typically rated for specific voltage ranges (e.g., 125V AC, 250V AC, 30V DC) and must be matched to your application’s voltage requirements.

Current Rating specifies the maximum current the switch contacts can carry continuously without overheating or damage. This rating is typically expressed in amperes (A) and may differ for resistive, inductive, or capacitive loads. For applications with high inrush currents (like motors or capacitive loads), select switches with appropriate inrush current handling capabilities.

Contact Resistance measures the electrical resistance across closed contacts, typically expressed in milliohms (mΩ). Lower contact resistance results in less power loss and heat generation. For low-voltage or low-current applications, low contact resistance becomes particularly important to ensure reliable circuit operation.

Insulation Resistance indicates how effectively the switch isolates conductors when contacts are open. Higher insulation resistance (typically measured in megohms) ensures minimal current leakage in the off state, which is critical for high-impedance circuits or safety applications.

Electrical Life specifies the number of operations the switch can perform while maintaining its electrical characteristics. This is typically lower than mechanical life and depends on factors like switching current, voltage, and load type. For applications requiring frequent switching under load, prioritize switches with higher electrical life ratings.

When selecting push button switches, always ensure that the electrical ratings exceed your application requirements with an appropriate safety margin. Consider not just normal operating conditions but also potential fault conditions, voltage spikes, and environmental factors that might affect electrical performance.

Environmental Protection Standards: IP Ratings and Durability

The operating environment significantly impacts push button switch performance and longevity. Understanding environmental protection standards helps ensure your selected switches can withstand the conditions they’ll face.

IP (Ingress Protection) Ratings define the switch’s resistance to solid objects and liquids. The rating consists of two digits: the first indicates protection against solid objects (0-6), and the second indicates protection against liquids (0-8).

Common IP ratings for push button switches include:

- IP40: Protected against solid objects larger than 1mm, no protection against liquids

- IP54: Dust-protected and resistant to splashing water

- IP65: Dust-tight and protected against water jets

- IP67: Dust-tight and protected against temporary immersion

- IP68: Dust-tight and protected against continuous immersion

For harsh industrial environments, outdoor applications, or areas exposed to cleaning processes, select switches with appropriate IP ratings to ensure reliability and longevity.

Operating Temperature Range specifies the minimum and maximum temperatures at which the switch can function reliably. Standard commercial switches typically operate between -10°C and +55°C, while industrial-grade switches might handle -40°C to +85°C or beyond. Ensure your selected switch can handle both the ambient temperature and any temperature rise due to current flow.

Chemical Resistance becomes critical in environments where switches may be exposed to oils, solvents, cleaning agents, or other chemicals. Materials like stainless steel, certain plastics, and specialized coatings offer enhanced chemical resistance for such applications.

Vibration and Shock Resistance specifications indicate the switch’s ability to maintain functionality when subjected to mechanical stresses. These are particularly important for automotive, aerospace, or industrial applications where equipment vibration is common.

When selecting push button switches for challenging environments, consider not just current conditions but also potential future changes, cleaning procedures, and maintenance activities that might expose the switches to additional stresses.

Physical Dimensions and Mounting Considerations

The physical characteristics and mounting requirements of push button switches are critical factors that affect installation feasibility, user interaction, and overall system design.

Mounting Hole Diameter is a fundamental specification for panel-mount switches. Common diameters include 16mm, 19mm, 22mm, and 30mm, with 22mm being particularly common in industrial applications. Ensure your panel design accommodates the required hole size and that the switch mounting hardware is compatible with your panel thickness.

Behind-Panel Depth indicates how much space the switch requires behind the mounting surface. This is crucial for installations with limited depth, such as thin control panels or space-constrained enclosures. Consider not just the switch body but also the space needed for wire terminations and bend radius.

Mounting Style varies across switch types:

- Panel Mount: Installed through a hole in a panel or enclosure, secured with a nut or similar hardware

- PCB Mount: Soldered directly to a printed circuit board

- Surface Mount: Attached to a surface without requiring a through-hole

- Snap-In Mount: Designed to snap into a pre-sized panel opening without additional hardware

- DIN Rail Mount: Designed to attach to standardized DIN rails in control cabinets

Terminal Type affects how electrical connections are made to the switch. Options include:

- Screw Terminals: Allow direct connection of wires, secured by screws

- Quick-Connect Terminals: Accept standard female quick-connect terminals

- Solder Terminals: Require soldering for wire attachment

- PCB Pins: Designed to be soldered into circuit boards

- Wire Leads: Pre-attached wires that eliminate the need for terminal connections

Actuator Style and Projection affect user interaction and aesthetic considerations. Options range from flush buttons to extended actuators, mushroom heads, key-operated switches, and illuminated buttons. The actuator style should match both functional requirements and user interface design principles.

When selecting push button switches, create detailed mounting specifications that consider not just the switch dimensions but also installation clearances, wire routing, operator access, and maintenance requirements. This comprehensive approach helps prevent installation issues and ensures optimal performance throughout the switch’s lifecycle.

Push Button On Off Switch

Plastic Push Button Switch

Stop Push Button Switch

Other Push Button Switch

Micro Push Button Switch

With Full Product Certification

What Are Push Button Switches and How Do They Work?

Push button switches are electromechanical devices designed to make or break electrical connections through manual actuation. When a user presses the actuator (button), the switch either completes or interrupts an electrical circuit, depending on its configuration. These switches consist of several key components:

The actuator (the button itself) is the part that receives physical input from the user. Behind this visible component lies the contact mechanism, which consists of conductive materials that either connect or disconnect when the actuator is pressed. The return mechanism, typically a spring, returns the actuator to its original position after release. Finally, the housing provides structural integrity and protection for the internal components.

The fundamental operation involves converting mechanical force into electrical action. When pressed, the actuator moves the contacts into a position that either completes or breaks the circuit. This simple yet reliable mechanism has made push button switches indispensable in countless applications where human interaction with electrical systems is required.

Push Button Light Switch

A push button light switch is an electrical switch designed to control lighting. It operates on a simple mechanism where pressing the button toggles the electrical circuit on or off. This action allows electric current to flow to the light fixture, illuminating the bulb, or stops the flow, extinguishing the light. The switch mechanism is typically spring-loaded, so it returns to its original position after being pressed, ready for the next operation. Push button switches can be single-pole, controlling one circuit, or multi-pole, controlling multiple circuits. They come in various styles and can include features like dimming or smart home connectivity. Often used for their classic aesthetic or ease of use, they are installed in residential and commercial settings.

Push Button Starter Switch

A push button starter switch is an electrical switch that initiates the starting sequence of an internal combustion engine. Typically found in vehicles, it replaces traditional key-operated ignition switches. When pushed, it activates the starter motor, which in turn cranks the engine to start running.

Modern vehicles often pair this switch with keyless entry and advanced security systems that require a key fob to be in proximity before the button will function. This design offers a more streamlined starting process and can also incorporate safety features to prevent the engine from starting if the vehicle is in gear or other unsafe conditions are detected.

Push Button Ignition Switch

A push button ignition switch is a modern vehicle starting mechanism that has replaced traditional key ignitions in many cars. It’s a button that, when pressed, activates the vehicle’s engine. The system typically works in conjunction with a smart key fob that communicates wirelessly with the car’s onboard computer, allowing for keyless entry and start.

The driver usually needs to have the key fob within the vehicle’s interior to start the engine. To operate, the driver either presses the brake pedal (for automatic transmissions) or engages the clutch (for manual transmissions) before pressing the ignition button. This button controls an electronic switch, which in turn activates the starter motor and ignites the engine. Some systems also incorporate additional security features to prevent unauthorized use or theft.

Lamp Push Button Switch

A lamp push button switch is a type of switch mechanism that controls the electrical current to a lamp. It operates on a simple push mechanism where pressing the button toggles the electrical circuit on or off. This action allows the lamp to be illuminated or extinguished without the need for turning a knob or flipping a traditional switch.

Push button switches can be found as a standalone device on the lamp body, embedded into the power cord, or as part of the lamp base. They are designed for ease of use and can vary in style from basic functional models to decorative ones that complement the lamp’s design. Their simplicity and reliability make push button switches a common choice for table and floor lamp designs in both residential and commercial settings.

Antique Push Button Light Switch

An antique push button light switch is a vintage-style electrical switch that operates on a simple push mechanism to turn lights on and off. These switches date back to the early 20th century and have a characteristic button design, often featuring two buttons: one for “on” and another for “off.” Unlike modern toggle or rocker switches, push button switches provide a unique tactile and auditory experience, with a distinct click sound when pressed.

They are typically made of brass, porcelain, or wood, adding to their antique aesthetic. While they offer an old-world charm, many have been updated to comply with modern electrical standards and can be used safely in contemporary homes. They’re popular among homeowners looking to add a touch of vintage elegance to their interior design.

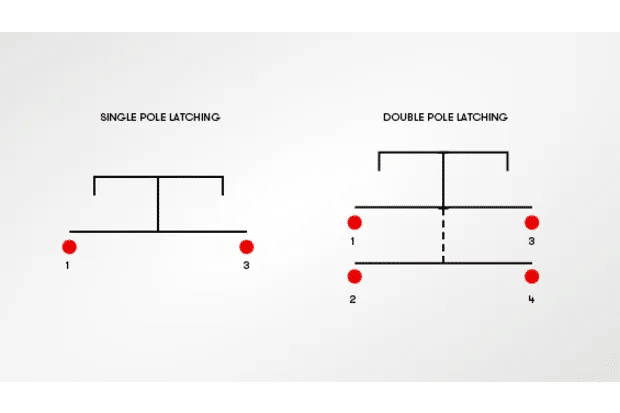

Latching Push Button Switch

A latching push button switch is a type of switch that maintains its state after being activated. Unlike a momentary switch which only closes the electrical circuit while being pressed, a latching switch will remain in the “on” or “off” position until it is pressed again. When the button is pushed, it latches into place, allowing the current to flow continuously until the button is pressed once more, which releases the latch and breaks the circuit, returning the switch to its original state.

This makes latching push button switches ideal for applications where a user needs to push the button and have the action remain in effect without continuous pressure, such as turning on and off lights, starting or stopping machines, or activating and deactivating electronic devices.

Marine Push Button Switch

A marine push button switch is a type of electrical switch designed for use in marine environments, where durability and resistance to harsh conditions like moisture, salt, and vibration are crucial. It operates through a simple push-to-make or push-to-break mechanism, controlling the flow of electricity in a circuit.

When the button is pressed, the circuit closes, allowing current to pass through; when released, the circuit opens, stopping the flow. These switches are typically made from corrosion-resistant materials such as stainless steel or plastic composites to withstand the challenging marine atmosphere. They are often found on boat dashboards, enabling the operation of lights, ignition systems, horns, and other electrical accessories. Marine push button switches also come with varying levels of waterproof ratings to ensure reliable performance even when exposed directly to water.

What's the Difference Between NO Contacts and NC Contacts?

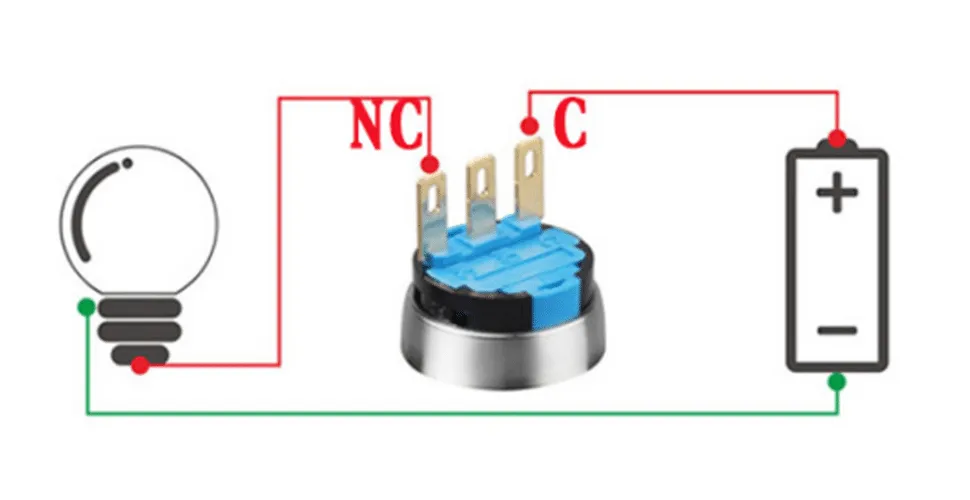

Push button switches come in various contact configurations that determine their circuit control capabilities. Understanding these configurations is essential for selecting switches that meet your specific electrical requirements.

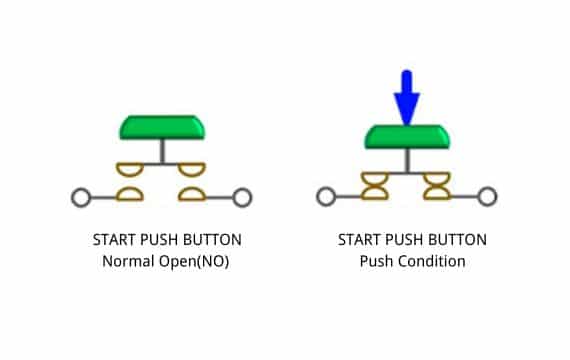

Normally Open (NO) contacts remain open (disconnected) in their resting state and close (connect) when the button is pressed. These are ideal for applications where the circuit should be activated only when the button is pressed, such as doorbells or start buttons.

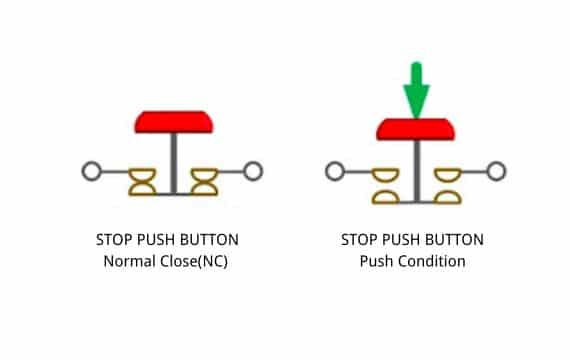

Normally Closed (NC) contacts remain closed (connected) in their resting state and open (disconnect) when the button is pressed. These are commonly used in emergency stop applications, door switches, or safety circuits where breaking the circuit is the desired action.

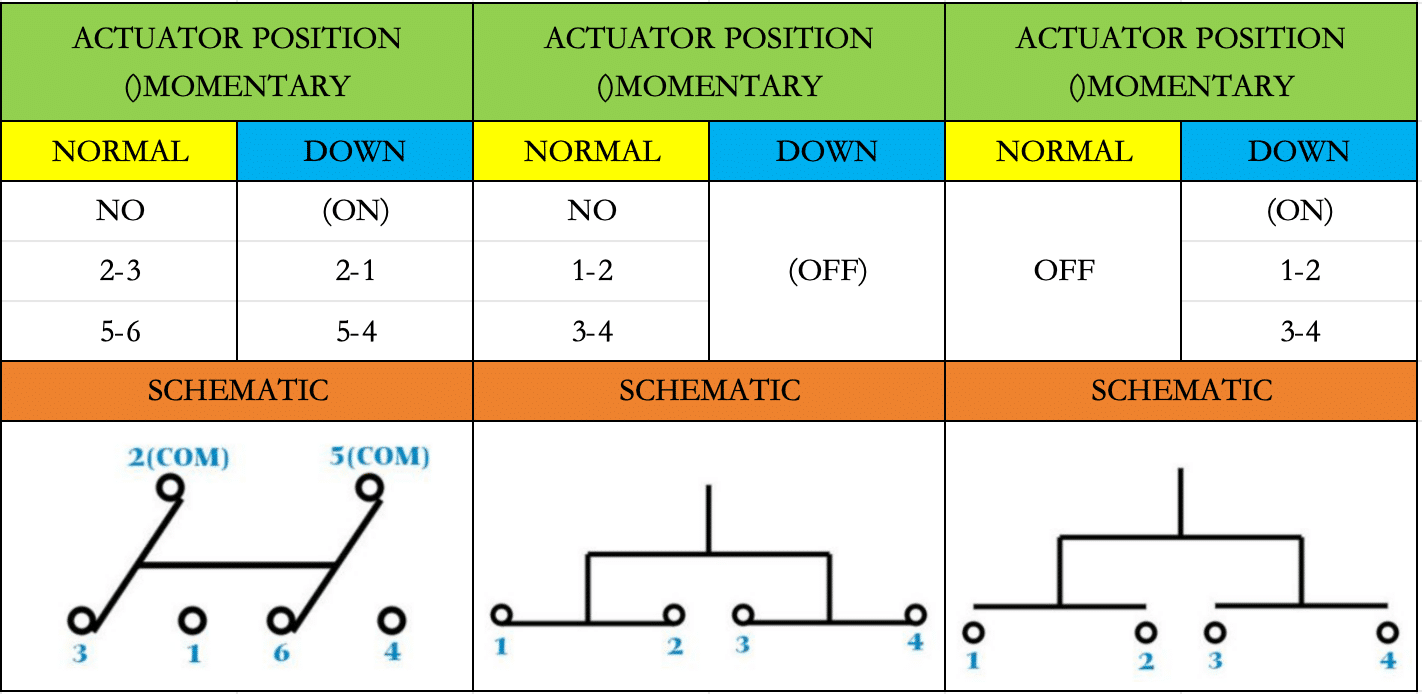

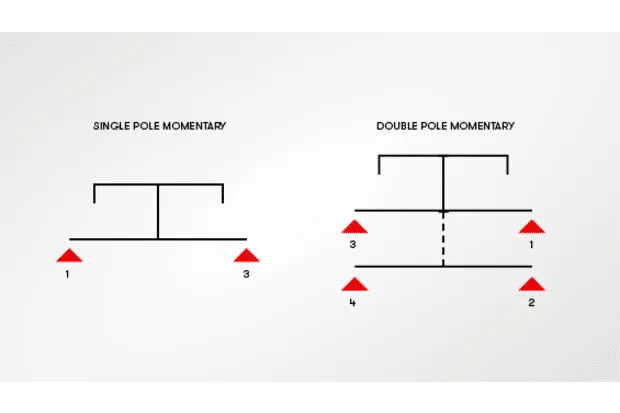

Examples of Common Switch Schematics Found in Datasheets

SPST (NO) Push Button Switch:

An SPST (Single Pole Single Throw) (NO) Push Button Switch is an electrical control designed to connect or break a circuit. It has one input and one output terminal. The (NO) signifies that it’s normally open, meaning the circuit is disconnected until the button is pressed, closing the circuit.

SPST(NC) Push Button Switch:

An SPST (Single Pole Single Throw) NC (Normally Closed) push button switch is a type of switch that breaks the circuit when the button is pushed. Upon release, it returns to its default state, completing the circuit. Often used in applications where a circuit interruption is required without a permanent switch position change.

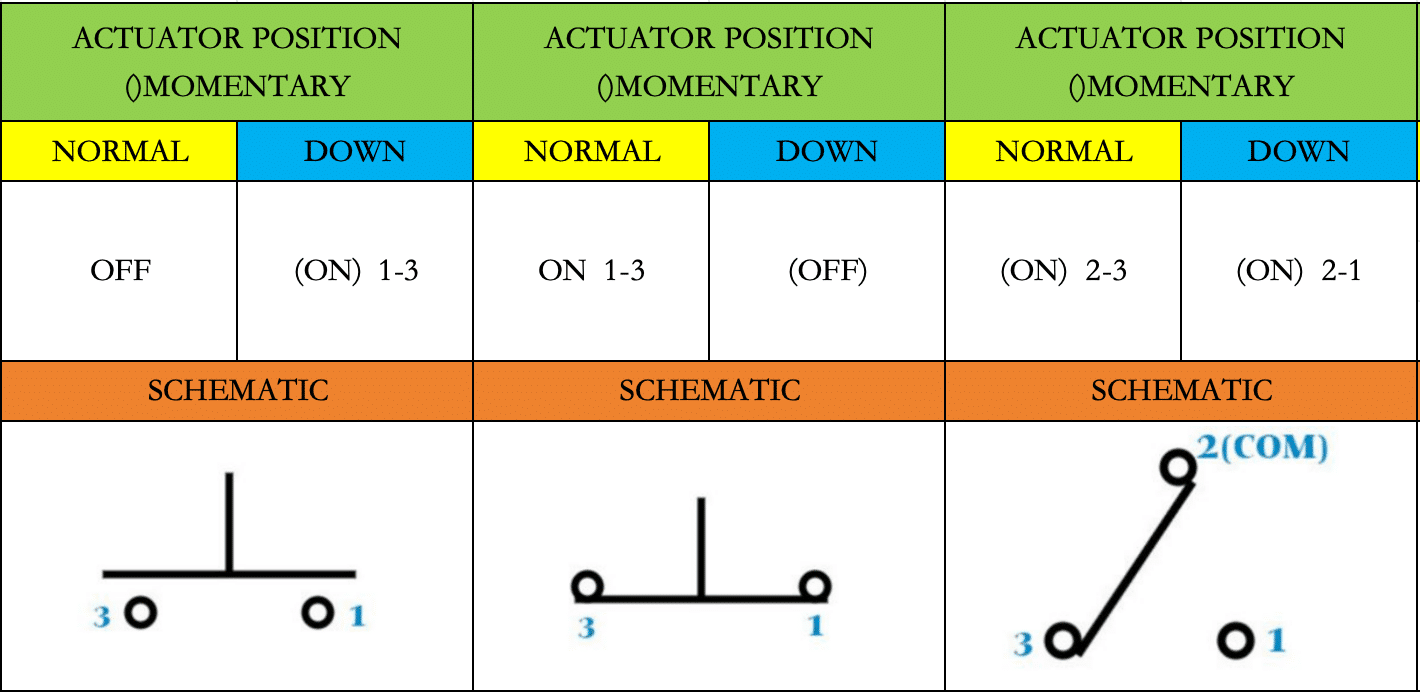

SPDT Push Button Switch:

A SPDT (Single Pole Double Throw) push button switch is an electromechanical device that controls the flow of an electrical circuit. It features a single input (pole) and two outputs (throws) to connect to different circuits, allowing the user to select between two paths with a push-button action.

DPDT Push Button Switch:

A DPDT (Double Pole Double Throw) push button switch is a type of electrical switch that can control two separate circuits simultaneously. It has two input contacts (poles) and two output positions (throws), allowing for complex switching operations such as reversing the current flow in a motor.

DPST(NC) Push Button Switch:

A DPST (Double Pole Single Throw) push button switch is an electrical switch that can control two circuits simultaneously. It has two ON positions and one OFF position, activated by a push button. When pressed, it connects or disconnects both circuits at the same time.

DPST(NO) Push Button Switch:

A DPST (Double Pole Single Throw) NO (Normally Open) push button switch is an electrical control featuring two separate circuits controlled by one button. When pressed, the button closes both circuits simultaneously. Being normally open means the switch completes the circuit only when the button is actively engaged.

What's the Difference Between Momentary and Maintained Push Button Switches?

Momentary push button switches change their state only while being actuated and automatically return to their normal position when released. These switches are ideal for applications requiring temporary activation, such as doorbells, keyboard keys, or test functions. The momentary action provides a clear tactile feedback to the user and prevents accidental continuous operation.

You can identify momentary switches in product specifications by looking for terms like “(ON)” or “mom ON” in their descriptions, where the parentheses indicate the temporary state. Common applications include:

- Automotive horns and signals

- Testing and reset functions

- Doorbell buttons

- Computer keyboard keys

- Machine control stations

In contrast, maintained push button switches (also called latching switches) remain in their actuated position until deliberately returned to their original state, typically by pressing the button again. These switches are marked simply as “ON” without parentheses in specifications. They’re ideal for applications requiring continuous operation without constant user interaction, such as:

- Power on/off controls

- Mode selection interfaces

- Equipment status controls

- Process activation systems

- Lighting controls

Push Button Switch Type

A momentary push button switch is a type of switch that only completes an electrical circuit while the button is actively being pressed. Upon release, the circuit breaks and the switch returns to its default, non-conductive state. These switches are commonly used for applications requiring short, intermittent user input signals.

A push button on-off switch is a type of switch mechanism that enables users to control an electrical circuit. By pressing the button, users can toggle the power supply between on and off states. These switches are commonly found in devices like lights and appliances for simple, intuitive operation.

.jpg)

A 12v push button switch is an electrical component that completes or interrupts a circuit when pressed. Designed to operate at 12 volts, it’s commonly used in low-voltage applications like automotive electronics, machinery controls, and consumer devices to start or stop electrical functions.

A micro push button switch is a small, momentary electrical switch designed to control a circuit. It operates when pressed, allowing current to flow, and breaks the circuit once released. Commonly used in electronic devices for simple on-off functions, they are characterized by their compact size and tactile feedback.

An electronic push button switch is a simple switch mechanism that controls some aspect of a machine or a process. It is operated by pressing a button, which closes or opens an electrical circuit, enabling or interrupting the current flow.

A push button dimmer switch is an electrical device allowing users to adjust the light intensity of a bulb. It operates with a button that, when pushed, either cycles through preset brightness levels or turns the light on/off, providing customizable lighting ambiance.

A mini push button switch is a small, momentary or latching switch that completes an electrical circuit when pressed. It is commonly used in electronic devices for simple on/off control or as an input for triggering functions.

An illuminated push button switch is a type of switch that features a built-in light to indicate its status. When pressed, it either closes or opens an electrical circuit, allowing current to flow or stop, and the illumination provides visual feedback or serves as a locator in low light conditions.

A waterproof push button switch is an electrical switch designed to operate through a push mechanism, allowing current to flow between its contacts. It’s engineered to be impervious to water and other liquids, ensuring functionality and safety in wet or damp environments.

A push button light switch cover is a protective and decorative plate that fits over the mechanism of a push button light switch, which controls the on/off state of lighting. It provides a surface for interaction with the switch and conceals the electrical box behind the switch.

A Start Stop Push Button Switch is an electrical control device featuring two buttons, typically green and red. The green “Start” button activates a machine or process, while the red “Stop” button terminates the operation. These switches are commonly used for industrial and commercial equipment to control power with a simple push action.

Beyond basic functionality, modern push button switches offer advanced features that enhance user interaction, provide visual feedback, and meet specialized application requirements. Understanding these options helps procurement professionals select switches that deliver optimal performance and user experience.

Illuminated Push Button Switches: LED, Neon, and Incandescent Options

Illuminated push button switches combine switching functionality with visual indication, making them invaluable for applications requiring operational status feedback. These switches incorporate light sources that can indicate power status, operational modes, or alert conditions.

The three primary illumination technologies each offer distinct advantages:

LED (Light Emitting Diode) illumination has become the dominant technology due to its numerous benefits:

- Exceptional longevity (50,000+ hours typical)

- Low power consumption (typically 20-30mA)

- Minimal heat generation

- Vibration resistance (no filament to break)

- Available in multiple colors (red, green, blue, white, yellow, and multicolor options)

- Consistent brightness throughout lifespan

LED-illuminated switches are ideal for modern applications where energy efficiency, longevity, and reliability are priorities. They’re particularly well-suited for battery-powered equipment or applications requiring color-coded status indication.

Neon illumination, while less common in new designs, offers:

- Direct operation from line voltage (120V/240V AC) without current-limiting resistors

- Distinctive orange-red glow that’s easily recognizable

- Good longevity (10,000+ hours typical)

- Moderate power consumption

Neon-illuminated switches remain useful in applications directly connected to AC power where the distinctive glow is desired or where simple AC line voltage indication is needed.

Incandescent illumination, the oldest technology, is increasingly rare but still found in some applications:

- Warm light quality

- Simple electrical characteristics

- Relatively short lifespan (1,000-5,000 hours)

- Higher power consumption

- More susceptible to vibration and shock damage

When selecting illuminated push button switches, consider not just the illumination technology but also:

Voltage matching: Ensure the illumination circuit voltage matches your system voltage or include appropriate dropping resistors/transformers.

Independent vs. dependent illumination: Determine whether the light should function independently of the switch position (e.g., to indicate power availability) or be linked to the switch state (e.g., to confirm activation).

Illumination color: Follow industry conventions where applicable (e.g., red for emergency, green for normal operation) and ensure consistency across your control interface.

Brightness requirements: Consider the ambient lighting conditions where the switch will be used and select appropriate brightness levels for clear visibility without causing glare or discomfort.

Anti-Vandal and Heavy-Duty Push Button Switches

For applications in public spaces, high-traffic areas, or harsh industrial environments, standard push button switches may not provide sufficient durability or security. Anti-vandal and heavy-duty push button switches address these challenges with enhanced design features.

Anti-vandal switches are specifically engineered to resist tampering, damage, and unauthorized access. Key features include:

- Robust metal construction, typically stainless steel or anodized aluminum, resistant to impacts, cutting tools, and prying attempts

- Flush or low-profile design that minimizes leverage points for tampering

- Sealed construction (typically IP65 or higher) to prevent damage from liquids, including deliberate attempts to introduce fluids

- Tamper-resistant mounting that prevents removal without specialized tools

- High actuation force requirements that prevent accidental activation while ensuring deliberate operation

These switches are ideal for public access equipment, outdoor control panels, transportation applications, security systems, and any environment where switches might be subject to abuse or tampering attempts.

Heavy-duty industrial switches focus on reliability under extreme conditions rather than vandalism resistance. Their features include:

- Enhanced mechanical life, often rated for millions of operations

- Higher electrical ratings for controlling substantial loads

- Reinforced construction to withstand frequent or forceful actuation

- Resistance to industrial contaminants like oils, coolants, and cleaning agents

- Extended temperature range operation for extreme environments

- Enhanced vibration and shock resistance for mobile equipment or high-vibration applications

When selecting anti-vandal or heavy-duty switches, consider not just the switch itself but also its mounting method and surrounding infrastructure. Even the most robust switch can be compromised if its mounting panel or wiring connections are vulnerable. A comprehensive approach to durability ensures reliable operation even in challenging environments.

Customization Options: Colors, Actuators, and Specialized Functions

Modern push button switch manufacturers offer extensive customization options that allow procurement professionals to select switches precisely matched to their application requirements, user interface design, and operational needs.

Color coding serves both aesthetic and functional purposes in control panel design. Standard colors often follow conventional meanings:

- Red: Emergency stop, off, danger, or critical functions

- Green: Start, on, normal operation, or safe condition

- Yellow/Amber: Caution, abnormal condition, or reset function

- Blue: Mandatory action or information

- White/Gray/Black: General functions without specific safety implications

Color selection should consider not just convention but also visibility in the operating environment, contrast with the mounting panel, and accessibility for operators with color vision deficiencies.

Actuator shape and texture options include:

- Flat: Minimal projection, suitable for space-constrained applications

- Raised: Easier to locate by touch, provides better tactile feedback

- Mushroom: Large actuation surface for emergency stops or frequently used functions

- Guarded: Protected by a ring or cover to prevent accidental activation

- Key-operated: Requires a key for activation, providing security for critical functions

- Textured: Provides enhanced grip and tactile identification

Specialized function switches address specific operational requirements:

- Emergency stop (E-stop) buttons: Distinctive mushroom-shaped red buttons on yellow backgrounds, designed for immediate system shutdown in hazardous situations

- Selector switches: Combine push button functionality with rotary position selection

- Dual-circuit switches: Provide both normally open and normally closed contacts in a single device

- Lockout switches: Can be secured in position with padlocks for maintenance safety

- Two-hand control switches: Require simultaneous activation of two separate buttons for safety-critical operations

- Foot switches: Pedal-operated versions for hands-free operation

Legend and marking options enhance operator understanding and reduce errors:

- Custom engraved or printed text

- Symbolic icons conforming to international standards

- Illuminated legends that are visible only when activated

- Multilingual markings for international applications

When specifying customized push button switches, provide detailed requirements including not just electrical and mechanical specifications but also precise color requirements (preferably with RAL or Pantone references), legend text and font specifications, and any special mounting or orientation requirements. This comprehensive approach ensures that the delivered switches meet both functional and aesthetic expectations.

Push button switches find applications across diverse industries, each with unique requirements and challenges. Understanding these industry-specific applications helps procurement professionals select switches that deliver optimal performance in their particular context.

Industrial Control Systems and Equipment

Industrial environments represent one of the largest application areas for push button switches, where they serve as critical human-machine interface components in control systems across manufacturing, processing, and utility operations.

Control panels and operator stations incorporate push button switches for machine control, process initiation, mode selection, and emergency shutdown. In these applications, switches must withstand frequent use while providing clear tactile feedback to operators who may be wearing gloves or working in low-visibility conditions. Industrial-grade switches typically feature:

- 22mm or 30mm mounting diameters conforming to international standards

- High IP ratings (typically IP65 or better) for protection against dust and moisture

- Robust construction with metal or high-strength thermoplastic housings

- High electrical ratings suitable for both direct load switching and PLC inputs

- Standardized color coding following IEC 60204 or similar standards

Emergency stop systems rely on specialized push button switches designed for immediate and reliable interruption of dangerous operations. These distinctive red mushroom-head buttons on yellow backgrounds must comply with safety standards like ISO 13850 and feature:

- Positive mechanical operation that physically forces contacts open

- Self-monitoring contacts that detect failures

- Latching mechanisms that maintain the stop condition until deliberately reset

- High visibility and accessibility from all relevant operating positions

Case Study: Automotive Assembly Line

A major automotive manufacturer upgraded their assembly line control stations with standardized push button switch panels. The solution included:

- IP67-rated switches to withstand cleaning procedures and industrial contaminants

- LED-illuminated buttons color-coded by function (green for start, red for stop, blue for reset)

- Emergency stop buttons positioned at one-meter intervals along the line

- Custom-engraved function labels in multiple languages

The result was a 35% reduction in operator errors, improved maintenance efficiency through standardization, and enhanced safety compliance. The higher initial investment in quality switches yielded significant long-term savings through reduced downtime and simplified spare parts inventory.

Automotive and Transportation Applications

Automotive and transportation applications present unique challenges for push button switches, including extreme temperature variations, constant vibration, exposure to fluids, and requirements for exceptional reliability in safety-critical functions.

Vehicle control systems incorporate push button switches for functions ranging from basic operations like horn activation to complex systems like cruise control engagement. Modern vehicles increasingly use push button ignition systems, electronic parking brakes, and drive mode selectors. These applications require:

- Extended temperature range operation (-40°C to +85°C typical)

- Resistance to automotive fluids including fuel, oil, and cleaning agents

- High vibration and shock resistance

- Low contact resistance for reliable low-voltage circuit operation

- Aesthetic design integration with vehicle interiors

Commercial transportation equipment such as buses, trains, and aircraft utilize specialized push button switches for both operator controls and passenger interfaces. These applications emphasize:

- Compliance with transportation-specific standards (e.g., EN 50155 for railway applications)

- Vandal-resistant construction for public-accessible controls

- Illumination visible in varying ambient light conditions

- Tactile feedback that remains effective despite vehicle motion

- Fire-retardant materials meeting transportation safety standards

Case Study: Electric Bus Manufacturer

An electric bus manufacturer faced reliability issues with dashboard controls in their initial production run. After analysis, they implemented a redesigned control system featuring:

- Sealed, anti-vandal push button switches with IP67 protection

- Custom-designed LED illumination matching the vehicle’s interior lighting scheme

- Switches tested to withstand 2 million operational cycles

- Standardized mounting dimensions allowing for easy field replacement

The improved switches eliminated field failures, reduced warranty claims by 78%, and enhanced driver satisfaction through improved tactile feedback and visibility. The manufacturer’s subsequent cost-benefit analysis revealed that the premium switches, despite a 40% higher initial cost, delivered a positive ROI within the first year of operation through reduced maintenance and downtime costs.

Consumer Electronics and Commercial Equipment

Consumer electronics and commercial equipment represent diverse application areas for push button switches, ranging from miniature tactile switches in portable devices to robust controls in commercial appliances and equipment.

Consumer electronic devices utilize push button switches as primary user interface elements. These applications prioritize:

- Compact dimensions and low profile for space-constrained designs

- Precise tactile feedback and consistent actuation force

- Aesthetic integration with product design

- Low noise operation for quiet environments

- Cost-effectiveness for high-volume production

Common examples include power buttons on computers, control buttons on audio equipment, and function buttons on household appliances. These switches typically operate at low voltages and currents but must maintain reliability through thousands of operations.

Commercial equipment such as vending machines, point-of-sale terminals, and self-service kiosks employ push button switches that balance durability with user-friendly operation. These applications require:

- Resistance to public use and potential abuse

- Clear visual identification and intuitive operation

- Reliable performance in varying environmental conditions

- Compatibility with both legacy systems and modern electronics

- Compliance with accessibility standards

Case Study: Self-Service Kiosk Manufacturer

A manufacturer of outdoor payment kiosks for parking facilities needed to address frequent switch failures that were causing revenue loss and customer dissatisfaction. Their solution involved:

- Replacing membrane switches with metal anti-vandal push button switches

- Implementing illuminated buttons with high-brightness LEDs visible in direct sunlight

- Selecting switches with IP68 rating to withstand extreme weather conditions

- Incorporating antimicrobial coatings on button surfaces for hygiene

The redesigned kiosks demonstrated 99.8% uptime compared to the previous 92% rate, significantly reducing maintenance costs and customer complaints. The enhanced user interface also reduced transaction times by an average of 15 seconds per customer, improving overall throughput and user satisfaction.

These case studies illustrate how thoughtful push button switch selection can deliver significant operational benefits across diverse applications. By understanding industry-specific requirements and challenges, procurement professionals can select switches that not only meet basic functional needs but also enhance overall system performance, reliability, and user experience.

Ensuring the reliability and performance of push button switches requires understanding quality standards, testing methodologies, and failure analysis techniques. This knowledge helps procurement professionals evaluate supplier claims and select switches that will perform consistently throughout their intended lifecycle.

Industry Standards and Certifications

Push button switches are subject to various industry standards and certification requirements that verify their performance, safety, and environmental compliance. Familiarity with these standards helps ensure that procured switches meet both regulatory requirements and performance expectations.

Safety certifications verify that switches meet established safety criteria for their intended applications:

- UL (Underwriters Laboratories) certification is crucial for products used in North American markets. Relevant standards include UL 508 for industrial control equipment and UL 1054 for special-use switches.

- CSA (Canadian Standards Association) certification addresses safety requirements for the Canadian market.

- VDE (Verband der Elektrotechnik) certification is important for European markets and verifies compliance with safety standards.

- TÜV certification provides independent verification of safety and quality, particularly valued in European markets.

International standards establish performance criteria and testing methodologies:

- IEC 60947 defines requirements for low-voltage switchgear and control gear, with IEC 60947-5-1 specifically addressing control circuit devices and switching elements.

- ISO 13850 establishes principles for the design of emergency stop functions, including requirements for emergency stop buttons.

- EN 60529 defines the IP (Ingress Protection) rating system for environmental protection.

- MIL-STD-202 outlines test methods for electronic and electrical components, including switches used in military and aerospace applications.

Environmental compliance certifications address material composition and environmental impact:

- RoHS (Restriction of Hazardous Substances) compliance ensures switches don’t contain restricted materials like lead, mercury, or cadmium above permitted thresholds.

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance addresses broader chemical safety concerns for products sold in the European Union.

- WEEE (Waste Electrical and Electronic Equipment) compliance relates to end-of-life recycling and disposal considerations.

When evaluating push button switches, verify that they carry appropriate certifications for your application and market. Request certification documentation from suppliers and confirm that certifications cover the specific models being considered, as certifications often apply to particular configurations rather than entire product families.

Testing Methodologies and Performance Verification

Comprehensive testing ensures that push button switches will perform reliably under actual operating conditions. Understanding common testing methodologies helps procurement professionals evaluate supplier claims and determine whether switches have been adequately validated for their intended applications.

Electrical performance testing verifies that switches meet their specified electrical characteristics:

- Contact resistance testing measures the electrical resistance across closed contacts, typically using a four-wire (Kelvin) measurement method for accuracy.

- Insulation resistance testing verifies the resistance between isolated conductors and between conductors and the switch housing, typically at high voltage.

- Dielectric strength testing (also called high-potential or hi-pot testing) applies a high voltage between isolated conductors to verify insulation integrity.

- Current carrying capacity testing verifies that switches can handle their rated current without overheating or contact damage.

- Switching capacity testing evaluates the switch’s ability to make and break circuits under load, which is more demanding than carrying current in an already-established circuit.

Mechanical durability testing assesses the switch’s ability to withstand repeated operation:

- Mechanical life testing involves actuating the switch repeatedly (often millions of cycles) to verify mechanical durability.

- Actuation force testing measures the force required to operate the switch and verifies consistency across multiple operations.

- Travel and over-travel measurement verifies that the switch mechanism moves through its specified range of motion.

- Return force testing ensures that the switch reliably returns to its resting position after actuation.

Environmental testing evaluates performance under various environmental conditions:

- Temperature cycling subjects switches to repeated temperature extremes to identify potential failure modes related to thermal expansion and contraction.

- Humidity testing exposes switches to high humidity environments to assess moisture resistance.

- Salt spray testing evaluates corrosion resistance, particularly important for switches used in marine or roadside applications.

- IP testing verifies protection against solid objects and liquids according to the specified IP rating.

- Vibration and shock testing assesses the switch’s ability to maintain functionality when subjected to mechanical stresses.

When evaluating push button switches, request detailed test reports from suppliers and pay particular attention to test conditions. Tests performed under conditions that match or exceed your application requirements provide the most relevant data for predicting real-world performance.

Failure Analysis and Troubleshooting Common Issues

Understanding common failure modes and troubleshooting techniques helps procurement professionals select switches less prone to specific issues and develop effective maintenance strategies for installed switches.

Common failure modes for push button switches include:

- Contact wear and erosion caused by electrical arcing during switching, particularly under inductive loads or when switching high currents.

- Contact contamination from dust, moisture, or chemical ingress that increases contact resistance or prevents proper contact closure.

- Mechanical fatigue of springs, actuators, or other moving parts after repeated operation.

- Plastic component degradation due to UV exposure, chemical contact, or thermal stress.

- Solder joint or terminal connection failures caused by vibration, thermal cycling, or improper installation.

- Illumination failures in illuminated switches, particularly with incandescent lamps or poorly designed LED circuits.

Preventive maintenance practices can significantly extend switch life:

- Regular inspection for visible damage, contamination, or signs of overheating

- Periodic measurement of contact resistance to detect degradation before failure

- Cleaning accessible switch components according to manufacturer recommendations

- Verification of proper terminal tightness and connection integrity

- Replacement of switches in critical applications according to a preventive maintenance schedule rather than waiting for failure

Troubleshooting techniques for switch-related issues include:

- Visual inspection to identify obvious damage, contamination, or misalignment

- Continuity testing to verify proper contact operation

- Voltage drop measurement across closed contacts to identify high-resistance connections

- Actuation force measurement to detect mechanical issues

- Thermal imaging to identify abnormal heating during operation

When selecting push button switches, consider not just initial performance but also long-term reliability factors. Switches with sealed contacts, gold-plated contact surfaces, reinforced mechanical components, and proven track records in similar applications typically offer superior reliability and lower total cost of ownership despite potentially higher initial costs.

Effective procurement of push button switches requires balancing initial purchase costs against long-term performance, reliability, and maintenance considerations. Strategic approaches to cost optimization help organizations achieve the best overall value rather than simply the lowest purchase price.

Total Cost of Ownership Analysis

Total Cost of Ownership (TCO) analysis provides a comprehensive view of push button switch costs throughout their lifecycle, enabling more informed procurement decisions than those based solely on purchase price.

Initial costs include:

- Purchase price of the switches themselves

- Associated components (mounting hardware, labels, protective covers)

- Procurement processing costs

- Inspection and testing costs

- Inventory carrying costs until installation

Installation costs encompass:

- Labor for mounting and wiring

- Panel modification or preparation

- Testing and commissioning

- Documentation updates

- Initial operator training

Operational costs over the switch lifecycle include:

- Maintenance labor and materials

- Downtime costs associated with switch failures

- Energy consumption (particularly relevant for illuminated switches)

- Performance impacts (e.g., operator efficiency affected by switch reliability or ergonomics)

- Compliance costs related to inspection and certification

End-of-life costs include:

- Removal and disposal

- Environmental compliance costs

- System reconfiguration or upgrade costs

A comprehensive TCO analysis often reveals that higher-quality switches with greater initial costs deliver lower total ownership costs through extended service life, reduced maintenance requirements, and fewer failure-related downtime incidents. For example, a premium anti-vandal switch costing three times more than a standard alternative might deliver ten times the operational life, resulting in significant long-term savings.

When conducting TCO analysis for push button switches, pay particular attention to application-specific factors that might dramatically affect lifecycle costs, such as:

- Exposure to harsh environmental conditions that accelerate deterioration

- Frequency of operation in high-use applications

- Criticality of the function controlled (where failures have significant operational or safety impacts)

- Accessibility for maintenance (where replacement labor costs might exceed component costs)

Supplier Evaluation and Partnership Development

The selection of appropriate suppliers is as important as the selection of the switches themselves. Strategic supplier relationships can deliver significant value beyond competitive pricing.

Key supplier evaluation criteria include:

- Product quality and reliability, verified through testing, certifications, and references from existing customers

- Manufacturing capabilities, including production capacity, quality control systems, and technological sophistication

- Technical support, including application engineering assistance, documentation quality, and responsiveness

- Supply chain reliability, including inventory management, lead times, and business continuity planning

- Financial stability, ensuring the supplier will remain viable throughout your product lifecycle

- Innovation capabilities, particularly important for long-term partnerships where product evolution is expected

Strategic partnership approaches that can enhance value include:

- Long-term agreements that provide volume pricing while ensuring supply continuity

- Vendor-managed inventory programs that reduce carrying costs while ensuring availability

- Joint development initiatives for customized or application-specific switch solutions

- Early supplier involvement in new product development to leverage supplier expertise

- Quality improvement partnerships focused on continuous enhancement of product performance

When evaluating push button switch suppliers, look beyond catalog offerings to assess their willingness and ability to serve as true partners in meeting your specific requirements. Suppliers who understand your application challenges and organizational goals can often deliver significantly greater value than those who simply fulfill orders.

Inventory Management and Just-in-Time Procurement

Effective inventory management balances availability against carrying costs, ensuring that appropriate push button switches are available when needed without excessive inventory investment.

Inventory optimization strategies include:

- ABC classification that categorizes switches based on criticality and usage rates, with different inventory policies for each category

- Min/max inventory systems that automatically trigger reordering when stock reaches predetermined thresholds

- Consignment arrangements where suppliers maintain inventory at your location but you only pay for items as they’re used

- Standardization initiatives that reduce the variety of switch types needed, allowing lower overall inventory levels

- Predictive maintenance programs that anticipate replacement needs before failures occur

Just-in-Time (JIT) procurement approaches minimize inventory while ensuring availability:

- Establishing reliable supplier relationships with guaranteed delivery timeframes

- Implementing electronic ordering systems that streamline procurement processes

- Developing contingency plans for critical components to mitigate supply chain disruptions

- Balancing JIT principles against the realities of lead times and minimum order quantities

Risk management considerations for push button switch procurement include:

- Identifying single-source components and developing mitigation strategies

- Monitoring for component obsolescence, particularly for switches used in long-lifecycle equipment

- Evaluating geopolitical and supply chain risks that might affect availability

- Maintaining appropriate safety stock levels for critical components

Effective inventory management for push button switches requires close collaboration between procurement, engineering, and maintenance functions to balance cost considerations against operational requirements. Regular review of usage patterns, failure rates, and supplier performance helps refine inventory strategies over time.

The push button switch market continues to evolve, with innovations addressing emerging application requirements and incorporating new technologies. Understanding these trends helps procurement professionals make forward-looking decisions that accommodate future needs.

Smart and IoT-Connected Push Button Switches

Traditional push button switches are increasingly incorporating smart features and connectivity options, transforming them from simple mechanical devices into intelligent system components.

Integrated electronics enhance traditional switch functionality:

- Microcontroller-equipped switches that can be programmed for specific behaviors

- Switches with built-in diagnostics that monitor their own performance and predict failures

- Multi-function switches that change behavior based on press duration or sequence

- Capacitive and touch-sensitive switches that eliminate mechanical wear concerns

Connectivity options enable switches to communicate with broader systems:

- Wireless protocols (Bluetooth, Zigbee, Wi-Fi) for cable-free integration

- Industrial network compatibility (Modbus, Profinet, EtherNet/IP) for seamless integration with control systems

- IoT gateway compatibility for cloud-based monitoring and control

- Power-over-Ethernet (PoE) capabilities that eliminate separate power wiring

Enhanced user interaction features improve the operator experience:

- Haptic feedback that provides tactile confirmation of activation

- Context-aware illumination that changes based on system state or available options

- OLED or LCD integrated displays that provide detailed status information

- Gesture recognition capabilities that expand control options beyond simple pressing

These smart switch technologies enable new applications and enhanced functionality, such as predictive maintenance based on usage patterns, adaptive interfaces that respond to operator behavior, and simplified installation through wireless communication. When evaluating push button switches for new designs, consider not just current requirements but also potential future needs for intelligence and connectivity.

Sustainable and Eco-Friendly Design Approaches

Environmental considerations are increasingly important in component selection, with push button switch manufacturers responding through sustainable design approaches and eco-friendly materials.

Material innovations address environmental concerns:

- Biodegradable or recyclable plastics for non-critical components

- Elimination of halogenated flame retardants in favor of more environmentally friendly alternatives

- Reduced use of rare or environmentally problematic metals

- Water-based instead of solvent-based coatings and finishes

- Packaging made from recycled or sustainable materials

Energy efficiency improvements reduce operational environmental impact:

- Ultra-low power illumination options using efficient LEDs

- Energy harvesting technologies that capture mechanical actuation energy

- Switches designed for low-voltage and low-current applications

- Reduced standby power consumption in smart switches

Lifecycle considerations address the entire environmental footprint:

- Design for disassembly and recycling at end-of-life

- Extended durability that reduces replacement frequency

- Modular designs that allow component replacement rather than complete switch replacement

- Reduced manufacturing energy requirements through process optimization

- Carbon footprint analysis and reduction initiatives

When evaluating push button switches through an environmental lens, consider not just compliance with current regulations but also alignment with broader sustainability goals and anticipation of future environmental requirements. Manufacturers who demonstrate comprehensive environmental responsibility often deliver better long-term value as regulations and customer expectations evolve.

Emerging Applications and Market Opportunities

New applications and market segments are creating opportunities for innovative push button switch designs and technologies, driving evolution in the component landscape.

Emerging application areas include:

- Electric vehicle infrastructure, including charging stations and battery management systems

- Renewable energy systems with specialized control and safety requirements

- Smart buildings and home automation incorporating user-friendly control interfaces

- Medical devices and healthcare equipment with stringent reliability and cleanliness requirements

- Augmented and virtual reality controllers requiring intuitive tactile interfaces

Market trends influencing push button switch evolution:

- Miniaturization driving development of smaller yet still tactile switches

- Increased emphasis on user experience and interface design

- Growing demand for customization and application-specific solutions

- Integration of switches with other interface technologies (touch screens, voice control)

- Enhanced durability requirements for shared and public-use equipment

Technology convergence creating new switch categories:

- Biometric authentication integrated with activation functions

- Switches with embedded environmental sensors

- Augmented reality interfaces that combine physical switches with virtual information

- Self-powered wireless switches that eliminate battery and wiring requirements

When developing long-term procurement strategies for push button switches, consider not just current requirements but also how emerging technologies and applications might affect future needs. Establishing relationships with innovative suppliers and maintaining awareness of technology trends helps ensure that your organization can quickly adopt beneficial new switch technologies as they mature.

Navigating the complexities of push button switch selection can be challenging. Our team of experts is ready to assist you in finding the optimal solutions for your specific applications.

We offer:

- Technical consultation to help define your exact requirements

- Sample evaluation to verify performance in your application

- Custom design services for specialized needs

- Comprehensive documentation to support your procurement process

- Ongoing technical support throughout your product lifecycle

Whether you need standard push button switches or customized solutions, our team is committed to helping you find the most effective and reliable options for your application.

Contact our technical specialists today to discuss your push button switch requirements and discover how we can help optimize your selection process.