Angle grinders are versatile power tools that can be used for a variety of applications, such as cutting, grinding, and polishing. These handheld devices are equipped with different types of switches that control their operation.

On-off switches and paddle type switches are two commonly used switch types in angle grinders. While both switches serve the same purpose of switching the grinder on and off, they differ in their design, functionality, and user experience.

In this article, we will explore the differences between on-off and paddle type switches on an angle grinder. We will discuss the pros and cons of each switch type, factors influencing user preference, safety precautions when using angle grinders with different switch types, tips for choosing the right switch type for your needs, and popular angle grinder models with on-off and paddle type switches.

Introduction Angle Grinder

Selecting the appropriate switch type for an angle grinder is crucial for safety, convenience, and performance. The objective of this blog post is to provide a detailed comparison between the on-off and paddle type switches to assist readers in making an informed decision.

In this discussion, an academic writing style will be employed that is objective and impersonal, avoiding personal pronouns.

Importance of choosing the right switch type for safety, convenience, and performance

The appropriate selection of a switch for an angle grinder is crucial to ensuring safety, convenience, and optimal performance. When it comes to angle grinder switches, there are two main types: on-off switches and paddle type switches. Understanding the difference between these two types of switches is important in making an informed decision on which switch is best suited for your needs.

Here are four reasons why choosing the right angle grinder switch is important for safety, convenience, and performance:

- Safety Features: Angle grinders with paddle type switches offer more safety features than those with on-off switches. This is because paddle type switches require both hands to operate the tool, making it harder for accidental start-ups to occur.

- Convenience: Paddle type switches provide greater convenience during use as they can be operated from multiple angles without having to reposition your grip on the tool.

- Optimal Performance: Paddle type switches allow for better control over the speed and direction of the grinding wheel compared to on-off switches. This can result in a smoother finish and increased accuracy during use.

- Ergonomics: Paddle type switches are designed with ergonomics in mind, providing greater comfort during extended periods of use compared to traditional on-off switches that may cause hand fatigue or discomfort over time.

Compare on-off and paddle switches in detail

Understanding the distinct advantages and disadvantages of switch types for angle grinders is essential in making an informed decision on which switch best suits one’s needs, ensuring optimal safety, convenience, and performance during use.

One of the most common switch types found in angle grinders is the on-off type switch. This type of switch requires a simple press to turn it on or off, making it easy to operate with one hand. However, its simplicity can also be a disadvantage as accidental activation can cause serious injuries or damage to property.

Another popular switch type found in angle grinders is the paddle switch. Unlike the on-off type switch, this type of switch requires constant pressure to keep the grinder running. Releasing pressure automatically turns off the tool providing additional safety features compared to other switches. In terms of convenience, it may take some time for users to get used to holding down the paddle button constantly while working; however, its added safety feature makes it an ideal choice for users who prioritize safety over ease-of-use during operation.

Ultimately, choosing between an on-off and paddle-type switch comes down to weighing up their respective advantages and disadvantages and determining what matters most based on individual preferences and requirements when using an angle grinder.

The Basics of Angle Grinder Switches

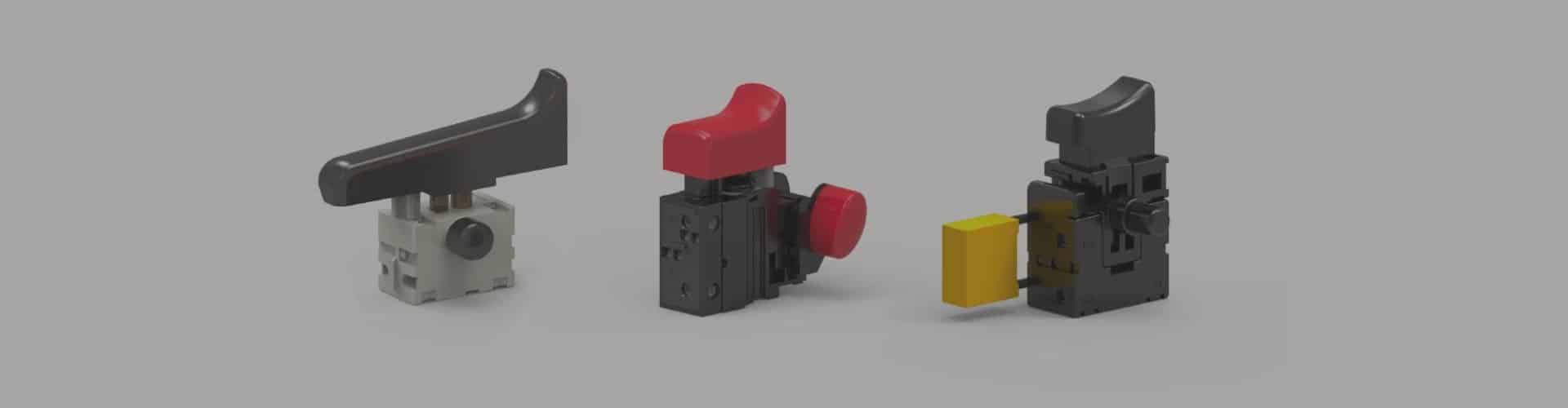

This section will discuss the basics of angle grinder switches, specifically the two main types: On-Off switch and Paddle Type (or Deadman) switch.

An On-Off switch is a basic type of switch that turns the grinder on or off with a simple push or pull action.

A Paddle Type switch, also known as a Deadman switch, requires continuous pressure to operate and will shut off immediately if the user releases it.

Definition of an On-Off switch

An on-off switch is a basic toggle or sliding switch that controls power flow to an angle grinder. It requires manual activation and deactivation by the user, which makes it a simple and reliable means of controlling the tool’s operation.

This type of switch can be found on most entry-level angle grinders and is easy to use for those who are new to using power tools.

A basic toggle or sliding switch that controls power flow to the grinder

The power flow to the angle grinder can be regulated through a simple sliding or toggle switch. These switches come in different types, such as paddle switch and slide switches.

The paddle switch is an ergonomic design that allows the user to easily turn on and off the angle grinder with one hand while still maintaining a firm grip on the tool. On the other hand, slide switches are more common and often found on lower-end models of angle grinders. They require two hands to operate and are less intuitive than paddle switches.

In terms of safety, paddle switches are considered safer because they automatically turn off when released by the user’s hand, whereas slide switches may accidentally remain in an ‘on’ position if not properly switched off. Ultimately, it comes down to personal preference and intended use when choosing between these two types of angle grinder switches.

Requires manual activation and deactivation by the user

The regulation of power flow to the angle grinder is dependent on manual activation and deactivation by the user through a switch mechanism, which can vary in design and safety features. Angle grinder switches come in different types such as toggle, sliding, and paddle switch grinders.

However, regardless of type, the user must manually activate or deactivate the switch to control power flow to the grinder. Paddle switches are a popular type of angle grinder switch because they allow for quick and easy shutdown during an emergency situation. Additionally, some paddle switches require two hands to operate which adds an extra layer of safety by preventing accidental startup or shutdown.

Overall, the manual activation feature on angle grinder switches provides users with greater control over their tool’s operation while also ensuring safe usage practices.

Found on most entry-level angle grinders

Entry-level angle grinders commonly feature a manual switch mechanism for controlling power flow, providing users with greater control over their tool’s operation while ensuring safe usage practices. This type of switch is typically referred to as an on-off switch and requires the user to physically press and release the button to activate or deactivate the grinder.

While this option may seem basic compared to more advanced models, it remains a popular choice due to its simplicity and ease of use. However, some entry-level angle grinders are also equipped with a paddle switch which allows for quicker activation and deactivation of the tool without having to release one’s grip on the device.

This type of switch is operated by pressing down on a paddle located on the side or rear of the grinder, making it ideal for tasks that require frequent stops and starts such as grinding small areas or working in tight spaces. Ultimately, whether choosing an on-off switch or paddle switch will depend on personal preference and intended use of the angle grinder.

Definition of a Paddle Type (or Deadman) switch

A paddle type switch, also known as a deadman switch, is a spring-loaded safety feature commonly found in professional-grade angle grinders.

This switch is engaged by pressing down a paddle or lever with one hand while holding the grinder.

It automatically cuts power when pressure is released from the paddle/lever, providing an extra layer of safety for the user.

Safety First: The Importance of Paddle Switches on Angle Grinders

To activate the safety mechanism on an angle grinder, one must apply pressure to a spring-loaded switch that is operated by a paddle or lever. This type of switch is commonly referred to as a paddle switch or deadman switch.

The purpose of this safety switch is to prevent accidental activation of the grinder, as it requires constant pressure from the operator’s hand in order for the tool to remain active.

In contrast, an on-off switch can be accidentally left in the ‘on’ position, which could potentially lead to injury if someone were to come into contact with the rotating disc without realizing that the grinder was still running.

Overall, the paddle or deadman switch is an important safety feature that helps prevent accidents and injuries when using an angle grinder.

Power cuts off automatically when the paddle/lever pressure is released

Moving on from the spring-loaded safety switch of an angle grinder, another important feature to consider is the type of switch used.

There are two common types of switches: paddle and slide. The paddle switch requires the user to press down on a lever or paddle with one hand while holding onto the grinder with the other. This type of switch is preferred by many users as it offers greater control over the tool, allowing them to turn it off quickly if needed.

Additionally, paddle switches often have a kickback brake which automatically cuts power when pressure is released from the paddle/lever, preventing accidents caused by sudden jerks or loss of control.

On the other hand, slide switches require users to move a button or slider up and down to turn on/off the tool, which can be difficult for some people with limited mobility or strength in their fingers.

Ultimately, choosing between a paddle vs slide switch comes down to personal preference and what feels most comfortable and safe for each individual user.

Commonly found in professional-grade angle grinders

Professional-grade angle grinders often incorporate the paddle switch, which is a common feature that enhances safety and reliability during operation. This type of switch allows for quick and easy shut-off by simply releasing pressure from the paddle or lever.

The on-off switch, on the other hand, requires a separate action to turn off the grinder, which can be cumbersome in certain situations. With its intuitive design and automatic power-cutting mechanism, the paddle switch has become a preferred option for professionals who require fast and efficient control over their grinding tasks.

Additionally, this feature reduces the risk of accidental start-up and helps prevent injuries caused by improper handling or misuse of an angle grinder. Overall, incorporating a paddle switch into an angle grinder design is a smart choice for manufacturers looking to enhance both user experience and safety in their products.

Pros and Cons of On-Off Switches

This section will discuss the pros and cons of on-off switches commonly found on angle grinders.

On-off switches are simple and intuitive to use, allowing for quick and easy operation. However, they lack the ability to control speed or adjust settings, limiting their versatility in certain applications.

Understanding these advantages and disadvantages is crucial when selecting an angle grinder that meets specific job requirements.

Pros:

This discussion focuses on the difference between an on-off switch and a paddle type switch on an angle grinder.

An on-off switch is characterized by its simple design, making it easy to use even for beginners. Generally less expensive than paddle type switches, they are suitable for light-duty grinding tasks where continuous operation isn’t required.

Simple design makes them easy to use even for beginners

Novice users find the uncomplicated design of these switches manageable to operate.

The paddle switch is a type of angle grinder switch that requires the user to press and hold down a button in order to keep the machine running. This design ensures safety as it allows the user to quickly stop the machine by releasing pressure on the button.

On-off switches, on the other hand, require a simple push or pull action to turn on and off respectively. While this may seem easier for beginners, it can be dangerous if accidentally pushed or bumped while using the tool.

Overall, both types of switches have their advantages and disadvantages depending on individual needs and preferences. However, for those just starting out with an angle grinder, paddle switches are generally recommended due to their safer design and ease of use.

Generally less expensive than paddle type switches

While the simple design of angle grinder switches makes them easy to use for beginners, it’s important to note that there are two main types of switches: the on-off switch and the paddle switch.

The former is typically less expensive than the latter and is operated by a simple push-button mechanism. This type of switch is suitable for straightforward tasks that do not require constant adjustments or prolonged usage.

Conversely, paddle switches are activated by squeezing a lever-shaped button which allows for more control over the tool’s speed and power output. While they may be slightly trickier to operate initially, paddle switches provide a greater level of precision and can reduce hand fatigue during extended periods of use.

It’s important to consider your specific needs when choosing between an on-off or paddle type switch on an angle grinder.

Ideal for light grinding tasks that do not require continuous operation

Angle grinder switches that are suitable for light-duty grinding tasks and do not require continuous operation are available at a lower cost than their counterparts.

These switches usually come in the form of on-off switches, as opposed to paddle switches. They are designed for use in situations where the user does not need to constantly turn the grinder on and off or adjust its speed.

This makes them ideal for tasks such as sharpening blades, removing rust, or polishing metal surfaces. While they may not be appropriate for heavy-duty grinding tasks, they can be a cost-effective option for those who only need to use an angle grinder occasionally or for lighter applications.

Cons:

The use of paddle type switches on angle grinders may pose certain risks if not handled with care. These types of switches lack the instant stop feature that could significantly enhance safety during operation, making it easier for accidents to occur.

Therefore, they are not recommended for heavy-duty or professional applications due to their limited control over the tool’s power and potential hazards that might arise from unintended continuous operation.

Safety Hazard: Angle Grinder Switch Misuse

Unintended continuous operation of the switch on an angle grinder poses a significant safety hazard that can result in accidents if not used with caution. The angle grinder switch is designed to control the power supply to the tool’s motor, and it comes in two types: on-off and paddle type.

Both switches are essential for controlling the speed and direction of the blade, but they differ in how they function. The on-off switch has only two positions, while the paddle type allows for variable speed control by sliding it back and forth. If accidentally left in the ‘on’ position or bumped during use, either switch can cause unintended continuous operation that may lead to injury or damage to property.

Therefore, users must be careful when operating an angle grinder and ensure that they turn off or disconnect the device from its power source when not in use to prevent such incidents from occurring.

Prioritizing Safety in Angle Grinder Operation: The Importance of Instant Stop Feature

The absence of an instant stop feature in angle grinders is a concerning factor that could compromise the safety of their operation. Angle grinder paddle switches, which are commonly used, lack this feature and can lead to accidents due to unintended continuous operation.

The inability to immediately halt the spinning disc increases the risk of injury, especially when the tool is mishandled or comes into contact with unintended objects. In contrast, on-off switches present a more effective mechanism for stopping the device’s movement promptly.

This feature is particularly crucial when working in hazardous environments or situations where speed control is necessary. Therefore, it is essential to prioritize safety by carefully considering the type of switch used in an angle grinder.

Angle Grinder Safety: Why Paddle Switches Matter

Despite the lack of an instant stop feature, angle grinders with on-off switches are still considered safe to use for most applications. However, when it comes to heavy-duty or professional tasks that require more control over the tool’s power, a paddle switch is recommended.

The paddle switch allows the user to adjust the speed and power output of the angle grinder, making it easier to work with different materials and achieve desired results. This level of control is not possible with an on-off switch, which can lead to damage or injury if used improperly.

Therefore, for those who frequently use power tools like angle grinders in their line of work, investing in one with a paddle switch is a wise decision.

Pros and Cons of Paddle Type Switches

This section will discuss the pros and cons of using paddle type switches on angle grinders.

The advantages of paddle type switches include their ease of use, as they allow for quick and intuitive operation. Additionally, they can be safer than on-off switches since they require continuous pressure to maintain power, reducing the risk of accidental activation.

However, one disadvantage is that their placement can sometimes make them difficult to access or accidentally trigger during use.

Pros:

The difference between an on-off and a paddle type switch on an angle grinder is significant. The paddle switch offers enhanced safety features that reduce the risk of accidents during high-power operation.

Additionally, it allows for better control over the grinding process, preventing unintended continuous operation. Due to these benefits, the paddle switch is the preferred choice for professional users and heavy-duty applications.

Enhanced safety features reduce risk during high-power operation

Enhancements in safety features for high-power operations of angle grinders have been developed to reduce the risk of accidents.

The switch on an angle grinder is a crucial component that controls its operation.

Paddle switches and on-off switches are two types commonly used in angle grinders.

A paddle switch is a safety feature that requires the user to hold down the switch continuously to keep it running.

This design ensures that the tool automatically shuts off when the user releases their grip, preventing accidental activation.

Additionally, some paddle switches come with lock-on functionality, which enables continuous use without holding down the switch.

However, this function should only be used by experienced users who can control the tool safely.

On-off switches, on the other hand, do not offer any additional safety features and require constant attention from users during operation to avoid accidents.

In summary, paddle switches are preferred for enhanced safety features as they reduce risks during high-power operations of angle grinders compared to on-off switches.

Allows for better control over the grinding process, preventing unintended continuous operation

In addition to enhanced safety features, angle grinder switches can also come in two types: on-off and paddle switch.

The paddle switch is a popular choice for many users as it allows for better control over the grinding process, preventing unintended continuous operation. With this type of switch, the user needs to continuously press and hold down the button in order to keep the grinder running. This ensures that the grinder only operates when intended and reduces the risk of accidents or injuries from unintentional use.

On the other hand, an on-off switch simply turns the grinder on or off with one push of a button, which may not provide as much control over the tool’s operation. Ultimately, choosing between these two types of switches depends on personal preference and the specific application at hand.

Preferred choice for professional users and heavy-duty applications

Angle grinder switches that allow for better control over the grinding process are the preferred choice for professional users and heavy-duty applications, ensuring greater precision and safety.

The angle grinder paddle switch is a prime example of such a switch, as it allows the user to turn on and off the machine with one hand while holding onto the handle with the other. This type of switch is also known as a dead man’s switch or a kill switch because it stops the machine from running automatically when released.

Professional users who need to work with large volumes of material or in confined spaces appreciate this type of switch because they can quickly stop the tool if necessary without losing their grip on it, which could lead to accidents.

Additionally, heavy-duty applications require switches that are more durable and can withstand constant use without failing. Therefore, angle grinder paddle switches are often made from high-quality materials such as metal or reinforced plastic, making them more reliable than their on-off counterparts.

Cons:

The use of paddle/lever type switches on angle grinders has some notable drawbacks. First, they can be uncomfortable or tiring to use for extended periods due to the need to maintain pressure on the paddle or lever.

Additionally, these types of switches are generally more expensive than on-off switches, which may make them less appealing to budget-conscious consumers.

Finally, inexperienced users may find paddle/lever switches more difficult to operate, as they have a steeper learning curve compared with simpler on-off switches.

Can be uncomfortable or tiring to use for extended periods due to the need to maintain pressure on the paddle/lever

Extended usage of the paddle/lever switch on an angle grinder can lead to discomfort and fatigue due to the continuous need to maintain pressure.

While this type of switch provides greater control over the tool, it may not be suitable for extended periods of use where comfort level is a concern.

The design of the paddle switch requires users to apply constant pressure with their hands or fingers in order to keep the grinder running, which can cause strain and discomfort over time.

Additionally, prolonged use of the paddle switch may result in hand fatigue and reduced productivity, as users may have to take breaks more frequently than they would with an on-off switch.

Therefore, when choosing between an on-off and paddle type switch for an angle grinder, it is important to consider how long you will be using the tool and whether or not you are comfortable maintaining pressure on the switch for extended periods.

Generally more expensive than on-off switches

The cost of implementing paddle switches on tools such as angle grinders is generally higher than that of traditional on-off switches. This is due to the added complexity and components required for the paddle switch design.

The paddle switch requires a larger housing, additional wiring, and a spring mechanism to ensure proper operation. Additionally, the paddle switch may have more advanced safety features compared to an on-off switch, which can also contribute to its higher cost.

However, the increased cost may be justified by the benefits of using a paddle switch such as improved ergonomics and increased safety during use. Ultimately, whether or not the added cost of a paddle switch is worth it depends on individual preferences and needs when operating an angle grinder or other tools with similar switches.

May have a steeper learning curve for inexperienced users

Novice users may encounter difficulties with the operation of paddle switches on angle grinders due to their increased complexity, potentially leading to frustration or safety concerns. Unlike simple on-off switches that are easy to operate, paddle switches require a certain level of skill and practice to master.

Inexperienced users may find it challenging to control the speed and direction of the grinder while operating the paddle switch. Furthermore, if not used properly, paddle switches can cause accidental start-ups or unintentional stoppages, which can pose safety hazards.

Thus, it is advisable for inexperienced users to receive proper training or guidance before using angle grinders equipped with paddle switches to avoid any mishap caused by the steep learning curve associated with them.

Factors Influencing User Preference

This section will discuss the factors that influence user preference for paddle type switches on angle grinders.

Two key factors that can significantly affect a user’s preference are their experience level and the nature of the project or task they are undertaking.

The discussion will explore how these factors can impact a user’s decision to choose between an on-off switch or a paddle type switch, and ultimately contribute to the overall safety and efficiency of using an angle grinder.

User’s experience level

This discussion focuses on the user’s experience level regarding the difference between an on-off and paddle type switch on an angle grinder.

Beginners may find the simplicity of an on-off switch preferable, while professionals often opt for paddle type switches due to their enhanced safety and control capabilities.

An academic writing style that is objective and impersonal is used in this paragraph, avoiding personal pronouns.

Beginners may prefer on-off switches due to their simplicity and ease of use

For those who are new to using angle grinders, the simplicity and ease of use offered by on-off switches may make them a more attractive option than paddle type switches. An on-off switch is a basic switch that only controls the power supply to the grinder. It is located on the top or side of the tool and can be turned on or off with a simple push.

On the other hand, a paddle switch requires more coordination between hand and finger movement to operate since it is located at the bottom of the tool and requires constant pressure to keep it running. While experienced users may prefer paddle switches for their precision control and safety features, beginners may find them difficult to use initially due to their design complexity.

Therefore, an on-off switch provides an uncomplicated alternative that allows novices to focus solely on mastering grinding techniques without worrying about controlling their equipment simultaneously.

Professionals generally choose paddle type switches for enhanced safety and control

While beginners may prefer the simplicity and ease of use of on-off switches, professionals tend to opt for paddle type switches when it comes to angle grinders.

This is because paddle switches offer enhanced safety and control, allowing the user to easily turn off the grinder in case of an emergency or adjust the speed as needed.

In addition, the placement of paddle switches allows for better grip and handling, reducing the risk of accidental start-ups or slips that could cause injury.

Ultimately, choosing between an on-off switch and a paddle switch depends on personal preference and level of experience with angle grinders.

Nature of the project/task

The nature of the project or task plays a crucial role in determining the type of switch that should be used on an angle grinder.

On-off switches are suitable for light-duty tasks that do not require continuous operation, while paddle-type switches are ideal for intensive long-duration tasks where maintaining control is crucial.

It is important to consider the demands of the project and choose the appropriate switch to ensure safe and efficient use of the angle grinder.

On-off switches can be suitable for light-duty tasks that don’t require continuous operation

On-off switches are suitable for tasks that do not necessitate continuous operation, making them ideal for light-duty applications. The angle grinder switch is a crucial component of the tool, and it can be either an on-off switch or a paddle switch.

On-off switches are basic switches that simply turn on and off the power to the tool. They are easy to use and cost-effective. However, they may not be suitable for heavy-duty tasks that require continuous operation because they lack the ability to lock in place.

Paddle switches, on the other hand, offer better control over the tool’s operation as they allow users to lock them into position during extended use. Therefore, when choosing between an on-off switch and a paddle switch for your angle grinder, consider the nature of your project/task and whether it requires continuous or intermittent use.

Paddle type switches are ideal for intensive long-duration tasks where maintaining control is crucial

While on-off switches are suitable for light-duty tasks, paddle type switches have proven to be ideal for intensive long-duration tasks where maintaining control is crucial.

In an angle grinder, the paddle switch allows the operator to turn the tool on and off by simply releasing or pressing down on a paddle located at the rear of the tool. This feature ensures that the user maintains better control over the tool and can quickly shut it off in case of an emergency.

Moreover, since these types of switches require constant pressure from the operator’s hand, they prevent accidental start-up and ensure safe usage during long-duration tasks.

Therefore, if you’re working with an angle grinder for extended periods of time or performing heavy-duty tasks that require precision and control, opting for a paddle type switch can make all the difference in terms of safety and efficiency.

Safety Precautions When Using Angle Grinders with Different Switch Types

Safety is a top priority when operating an angle grinder, regardless of the type of switch. General safety tips include wearing appropriate personal protective equipment (PPE), securing workpieces, and keeping the work area clean.

However, additional precautions are necessary for on-off switches and paddle type switches to ensure safe operation. It is essential to follow specific guidelines when using each switch type to prevent accidents and injuries.

General safety tips applicable to both switch types (e.g., wearing appropriate PPE, securing workpieces, keeping work area clean)

It is crucial to adhere to general safety precautions when operating an angle grinder, regardless of the type of switch it has.

One critical safety issue that needs attention is the proper use of personal protective equipment (PPE). This includes wearing eye and ear protection, as well as gloves and a face mask if necessary. Angle grinders can generate a lot of dust and debris, which may cause injuries or respiratory problems if inhaled.

Securing workpieces is also essential for safe angle grinder operation. Workpieces should be clamped firmly before grinding or cutting to prevent them from moving during operation.

Additionally, keeping the work area clean and free from clutter can help prevent accidents caused by tripping over cords or stepping on objects.

By following these general safety tips and using the correct safety equipment, operators can help reduce the risk of injury while using angle grinders with any type of switch.

Additional precautions specific to on-off switches

When using an on-off switch on an angle grinder, there are additional precautions that should be taken to ensure safety.

It is important to always make sure the tool is switched off before plugging it in or changing accessories.

Additionally, when the grinder is not in use, it should be stored with the switch locked in the “off�?position to avoid accidental activation.

These measures can help prevent injuries and damage to equipment.

Ensuring tool is switched off before plugging it in or changing accessories

Prior to using an angle grinder, it is crucial to ensure that the tool is not powered on by verifying that it is switched off and unplugged or disconnected from its power source.

This safety measure should be taken every time the tool is used, even when changing accessories or performing maintenance tasks.

The switch on an angle grinder can be either an on-off switch or a paddle type switch. Regardless of the type of switch, ensuring that the tool is completely off before making any adjustments or changes is essential for preventing accidents and injuries.

Some angle grinders may also come with additional safety features such as a lock-on button which prevents accidental activation of the tool. It is important to take full advantage of these features and always prioritize safety when operating any power tools.

Avoiding accidental activation by storing grinder with the switch locked in the “off” position when not in use

To further prevent accidental activation of an angle grinder, it is recommended to store the tool with the switch locked in the ‘off’ position when not in use.

This precautionary measure becomes more crucial if the angle grinder has a paddle switch instead of an on-off switch. Paddle switches are known for being more sensitive and can easily be triggered unintentionally if left unlocked.

By securing the switch with a lock, you eliminate any chance of inadvertently starting up the grinder while handling or transporting it, reducing potential risks and ensuring safety.

Additional precautions specific to paddle type switches

This section addresses the additional precautions specific to paddle type switches when operating an angle grinder.

It is essential to maintain a proper grip on the grinder with both hands during operation, ensuring that one hand is always holding the paddle or lever.

Additionally, it is important to avoid fatigue by taking regular breaks if using a paddle switch for extended periods.

These measures can help prevent accidents and injuries while working with angle grinders.

Maintaining a proper grip on the grinder with both hands during operation (one hand should always be holding the paddle/lever)

Maintaining a secure grip on the angle grinder by utilizing both hands and holding onto the paddle/lever during operation is crucial for ensuring safety and precision.

This is especially important when using a paddle switch, as it requires constant pressure to keep the grinder running.

By using both hands, one to hold onto the body of the grinder and the other to operate the paddle switch, you are able to maintain control over the tool and prevent any accidental slips or drops.

Additionally, this grip allows for greater precision in your work, as you are better able to guide the grinder along your desired path.

Overall, proper hand placement and grip can greatly enhance both safety and performance when using an angle grinder with a paddle switch.

Avoiding fatigue by taking regular breaks if using a paddle switch for extended periods

Taking regular breaks when using an angle grinder with a paddle switch for extended periods can help prevent fatigue and ensure optimal performance. Paddle switches require the operator to continuously hold down the switch, which can cause hand and arm fatigue over time.

This type of switch is commonly found on larger angle grinders as it provides better control during use. However, prolonged use without taking adequate breaks can lead to decreased productivity due to muscle fatigue, increased risk of injury due to reduced grip strength, and decreased accuracy in workmanship.

To avoid these issues, operators should take regular breaks every 20-30 minutes when using a paddle switch for extended periods. This will allow them to rest their hands and arms while also ensuring that they are able to maintain consistent performance throughout their workday.

Tips for Choosing the Right Angle Grinder Switch Type

When choosing the right angle grinder switch type, it is important to assess your skill level and experience using such tools.

Additionally, you should determine your intended usage, whether it be for professional or DIY purposes and heavy-duty or light-duty applications.

Consider any personal preferences or physical limitations that may affect your ability to use a specific switch type comfortably.

Moreover, evaluate the importance of safety features for your intended applications and set a budget while weighing it against the potential benefits and drawbacks of each switch type.

Assess your skill level and experience using angle grinders

Proficiency in operating angle grinders is a crucial factor in ensuring safety and achieving desired results. Before choosing the type of switch for an angle grinder, it is important to assess one’s skill level and experience using the tool. Here are some considerations to keep in mind:

- Familiarity with the tool: If you have never used an angle grinder before, it may be best to start with a paddle switch as it allows for easier control over the speed and direction of the disc.

- Hand strength: Paddle switches require more force to operate compared to on-off switches. If you have weaker hand strength, then an on-off switch may be a better option.

- Safety concerns: An on-off switch can be accidentally triggered while in use if not properly secured or if there is a sudden jolt or vibration. A paddle switch requires constant pressure from the operator, reducing the likelihood of accidental activation.

- Task requirements: Consider the task at hand when choosing your switch type. For example, if you need frequent stops and starts during your work, such as when cutting through thick metal pieces or changing discs frequently, then a paddle switch might be more efficient.

Overall, understanding your own skill level and comfort with operating an angle grinder should guide your decision when selecting between an on-off or paddle type switch for optimal results and safety precautions.

Determine your intended usage (professional or DIY, heavy-duty vs. light-duty applications)

The intended usage of an angle grinder, whether for professional or DIY purposes and for heavy-duty versus light-duty applications, should be considered when selecting the appropriate switch type.

An on-off switch is a basic switch that turns the tool on and off with a simple push button mechanism. This type of switch is suitable for light to medium duty grinding applications where the user does not need frequent changes in speed or switching between tasks. On-off switches are also commonly found in lower-end angle grinders.

On the other hand, a paddle switch allows for more precise control over the tool’s operation and is ideal for heavy-duty or extended use. The paddle-type switch requires constant pressure to operate the tool, which prevents accidental start-ups and increases safety. Furthermore, paddle switches allow users to quickly turn off the machine in case of an emergency by simply releasing their grip on the paddle.

Therefore, understanding your intended usage of an angle grinder can help you choose between an on-off switch or a paddle-type switch that suits your needs best.

Consider any personal preferences or physical limitations that may affect your ability to use a specific switch type comfortably

The selection of the appropriate switch type for an angle grinder should also take into account any personal preferences or physical limitations that may influence the user’s level of comfort and ease when operating the tool.

For instance, if you have limited hand dexterity, a paddle switch may be easier to activate than an on-off switch. On the other hand, some users may prefer an on-off switch because they find it more intuitive and responsive.

When considering personal preferences, it’s important to note that some individuals may simply prefer one type of switch over another due to their prior experiences with similar tools. Additionally, certain applications may require specific types of switches to ensure safety and precision while using an angle grinder.

Ultimately, selecting between an angle grinder paddle switch or on-off switch will depend on your individual needs and preferences. By taking into account these factors, you can ensure that you choose a switch that is comfortable to use and meets your requirements for smooth operation.

Evaluate the importance of safety features for your intended applications

Assessing the significance of safety features for the intended applications of an angle grinder is a crucial aspect that should not be overlooked in order to ensure safe and efficient usage.

While both on-off and paddle type switches are commonly used in angle grinders, paddle switches are typically considered safer due to their design. Paddle switches require continuous pressure from the user’s hand to stay engaged, which means that if the user loses grip or control over the tool, it will automatically shut off. This feature helps prevent accidental startups or unintended uses when handling the grinder.

In addition to paddle switches, other safety features that can enhance safe usage include lock-on mechanisms, adjustable guard systems, and anti-vibration handles. Lock-on mechanisms allow users to lock the switch in place so they don’t have to continuously apply pressure while using the tool, but this feature should be used with caution as it increases the risk of accidental use when left unattended.

Adjustable guard systems allow users to adjust the protective guard around the grinding wheel according to their needs for added protection against sparks and debris. Anti-vibration handles help reduce operator fatigue by dampening vibrations caused by prolonged use of the tool.

Ultimately, choosing an angle grinder with appropriate safety features for your specific application is essential for maintaining a safe work environment and minimizing potential accidents or injuries.

Set a budget and weigh it against the potential benefits and drawbacks of each switch type

One critical consideration when selecting an angle grinder is to assess the financial implications of purchasing a tool with a paddle switch versus an on-off switch and weigh them against potential benefits and drawbacks. Generally, paddle switches are more expensive than on-off switches because of their added safety features.

Paddle switches require constant pressure to operate, which prevents accidental start-ups and enhances user control. On the other hand, on-off switches only require one push to turn the grinder on or off, making them convenient for quick tasks but also increasing the risk of unintentional activation.

When setting a budget for an angle grinder, it is important to consider how frequently you will be using the tool and in what conditions. If you plan to use your grinder regularly and in potentially hazardous environments, investing in a paddle switch may be worth the extra cost for added safety measures. However, if you only plan to use your grinder occasionally or in less risky scenarios, an on-off switch may suffice.

Ultimately, weighing the potential benefits and drawbacks of each switch type against your budget can help ensure that you make an informed decision when selecting an angle grinder that meets both your needs and financial limitations.

Popular Angle Grinder Models with On-Off and Paddle Type Switches

This section will discuss popular angle grinder models that feature either on-off switches or paddle type switches.

For on-off switch models, examples include those from Black & Decker and Ryobi.

Meanwhile, popular angle grinder models with paddle type switches include those manufactured by Dewalt and Bosch.

It is important to note the differences between these types of switches when selecting an angle grinder for your specific needs.

Provide examples of popular angle grinder models that feature on-off switches (e.g., Black & Decker, Ryobi)

There are various popular angle grinder models that feature on-off switches, such as the Black & Decker and Ryobi brands.

On-off switches are different from paddle type switches in that they are simpler to operate and easier to control.

These types of switches have received positive user reviews for their convenience and user-friendly design.

Include brief descriptions, specifications, and user reviews

The following section provides a comprehensive overview of the characteristics and opinions regarding the various types of switches commonly found on angle grinders.

Angle grinder paddle switch is one such type that is widely used in many models. This type of switch is located at the rear of the tool, and it allows for easy one-handed operation without having to take your eyes off the workpiece. Additionally, some models come with a lock-on feature that enables continuous operation without having to hold down the trigger constantly.

When it comes to specifications, paddle switches are known for their durability and reliability, making them ideal for heavy-duty applications. User reviews indicate that most people find this type of switch intuitive and easy to use. However, some users have reported instances where accidental activation occurred due to unintentional pressure on the trigger when holding onto the tool.

Overall, angle grinder paddle switches offer convenience, ease-of-use, and reliability that make them a popular choice among professionals and DIY enthusiasts alike.

Provide examples of popular angle grinder models with paddle type switches (e.g., Dewalt, Bosch)

This subtopic delves into popular angle grinder models equipped with paddle type switches. These include the Dewalt DWE402N, Bosch GWS10-45P, and Makita GA4530.

The Dewalt DWE402N boasts a powerful 11-amp motor, adjustable guard, and ergonomic grip for user comfort.

The Bosch GWS10-45P features a 4.5-inch wheel diameter, 10-amp motor, and vibration control technology for enhanced precision.

Users praise the Makita GA4530 for its lightweight design and durability in heavy-duty applications.

Include brief descriptions, specifications, and user reviews

Providing comprehensive information regarding the switch options available for angle grinders, this section presents concise yet detailed descriptions and objective user reviews that could facilitate informed decision-making for prospective buyers.

Angle grinder paddle switches are becoming increasingly popular among professionals and DIY enthusiasts alike due to their ergonomic design that offers greater control and safety during use.

The Dewalt DWE402N is a powerful 11-amp paddle switch angle grinder with a dust ejection system that helps increase durability by ejecting damaging dust and debris particles. It has received positive user reviews for its smooth operation, easy-to-use paddle switch, and comfortable grip.

Another popular option is the Bosch GWS13-50VSP-DG angle grinder with variable speed control, which allows users to adjust the speed according to different materials and applications. Its ergonomic paddle switch has been praised by users for providing better hand positioning and comfort during prolonged use.

Overall, these two examples of angle grinder models with paddle switches demonstrate how this type of switch can enhance both performance and safety while offering greater convenience to users.

Conclusion

In summary, the on-off and paddle type switches are two common switch types found in angle grinders. The former is a simple on/off switch with no additional features, while the latter requires continuous pressure to operate. User preferences for each switch type are influenced by various factors such as safety, ease of use, and personal preference.

When selecting an angle grinder, it is essential to carefully consider these factors to ensure that you choose the one that best meets your needs and priorities.

Recap the key differences between on-off and paddle type switches on angle grinders

Understanding the contrasting functionality of the two types of switches found on angle grinders is essential for users to make informed decisions when choosing the appropriate switch for their specific needs.

The on-off switch, also known as a thumb switch or a trigger switch, is located at the rear of the grinder and requires constant pressure from the user’s finger to operate. This type of switch is suitable for tasks that require short periods of use, such as cutting or grinding small pieces.

On the other hand, a paddle switch is located on top of an angle grinder and can be operated by pressing down with one’s entire hand. This feature allows for better control over longer periods of use, making it ideal for those who need to grind or cut larger surfaces. Additionally, paddle switches typically have an automatic shut-off feature that turns off the grinder when pressure is released from the paddle, providing added safety benefits.

In summary, understanding these key differences between on-off and paddle type switches on angle grinders can help users make informed decisions about which type of switch will best suit their needs based on how they plan to use their tool.

Reiterate the factors influencing user preferences for each switch type

The functionality and ergonomics of the switch types found on angle grinders are influenced by various factors, ultimately driving user preferences towards one type over the other.

When it comes to on-off switches, they are often preferred for their simplicity and ease of use. These switches only require a single press to turn the grinder on or off, which can be a useful feature in situations where precision control is not required. Moreover, on-off switches tend to be more durable than paddle switches as they have fewer moving parts that may wear out over time.

On the other hand, paddle switches offer greater control and safety compared to on-off switches. By design, these switches require continuous pressure from the user’s hand to keep the grinder running. This feature ensures that accidental activation is less likely to occur when setting down or picking up the tool. Additionally, paddle switches allow users to vary speed more precisely by modulating finger pressure while holding onto the tool handle with both hands.

As such, users who prioritize safety and precision may prefer angle grinders with paddle-type switches rather than on-off ones.

How to Choose the Right Switch for Your Angle Grinder

Before selecting an angle grinder, it is crucial for potential users to carefully evaluate their specific needs and priorities in order to make an informed decision regarding which switch type is most appropriate for their intended use.

The two main types of switches available on angle grinders are the on-off switch and the paddle switch. While both can effectively turn the tool on and off, they differ in terms of user preference.

The on-off switch is a simple button that can be easily manipulated with one hand. However, it may not be as convenient for extended use as the paddle switch.

The paddle switch allows for more control over the tool because it requires constant pressure to operate, making it less likely to accidentally turn on or off during use.

Overall, choosing between an on-off and a paddle type switch depends largely on personal preference and intended use. It is important for potential users to consider factors such as comfort, safety, and ease of use before making a final decision.

Frequently Asked Questions

How do I clean my angle grinder switch?

To clean an angle grinder switch, it is important to first unplug the tool and remove any attachments.

Then, using a soft cloth or brush, gently clean around the switch area to remove any debris or build up. It may be necessary to use a small amount of cleaning solution, such as rubbing alcohol, on tougher stains or grime.

After cleaning, it is important to let the switch dry completely before plugging in and using the tool again.

Regular maintenance and cleaning of an angle grinder switch can help prolong its lifespan and ensure safe operation during use.

Can I use an angle grinder with a faulty switch?

Using an angle grinder with a faulty switch is not recommended as it poses a significant safety hazard. A faulty switch can cause the grinder to turn on unexpectedly or fail to turn off, leading to serious injury or damage.

The switch is a crucial component in controlling the speed and power of the grinder, and any malfunction can compromise its functionality. It is recommended to inspect the switch regularly for signs of wear or damage and replace it immediately if necessary.

Moreover, always ensure that the tool’s power supply is disconnected before making any repairs or adjustments to prevent accidental activation of the grinder.

What is the average lifespan of an angle grinder switch?

The average lifespan of an angle grinder switch can vary depending on various factors, such as the frequency of use, the quality of the switch, and how well it is maintained.

In general, a high-quality switch that is used regularly and properly maintained can last for several years. However, if the switch is poorly made or not cared for correctly, it may fail prematurely.

It is essential to regularly inspect and maintain an angle grinder’s switch to ensure its longevity and safe operation. If any signs of wear or malfunction are detected, it should be replaced immediately to avoid potential safety hazards.

Are there any special maintenance requirements for paddle type switches?

Paddle type switches are commonly used in angle grinders and have become popular due to their ergonomic design. These switches are generally more comfortable to use and provide better control over the machine.

As for maintenance, it is recommended to clean the switch periodically with a dry cloth to avoid any accumulation of dirt or debris. However, there are no specific maintenance requirements for paddle type switches that differ from those of other types of switches.

Regardless of the switch type, it is essential to ensure that it is functioning correctly and replaced promptly if necessary as part of routine grinder maintenance.

Can I modify my angle grinder switch to switch between on-off and paddle type?

Modifying an angle grinder switch to switch between on-off and paddle type is not recommended. It may seem like a simple task, but it can be dangerous and potentially damage the grinder.

Switches are designed specifically for the tool they are used with, and modifications can result in improper functioning or even electrical hazards. Additionally, manufacturers caution against altering their tools as it voids warranties and exposes users to risks.

It is best to use the appropriate switch type for the intended use of the angle grinder and follow proper maintenance procedures for safe operation.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd