Push button power tool switches are an essential component of power tools that we use in our daily lives. These switches allow us to control the operation of a tool by turning it on or off as per our requirements.

However, not many people are aware of the intricate mechanisms that enable these switches to function effectively. Understanding the inner workings of push button power tool switches can provide valuable insights into their design, functionality, and maintenance.

This article aims to explore the different types of push button power tool switches commonly used today and their working principles. Additionally, it will provide troubleshooting tips for common issues encountered while using these switches and answer frequently asked questions related to them.

By delving into the world of push button power tool switch mechanics, this article intends to equip readers with a deeper understanding of how these devices operate and how they can be maintained for optimal performance.

Introduction

Understanding the inner workings of power tool switches is important for users to ensure safe and efficient operation.

Among various types of power tool switches, push button switches are commonly used in handheld tools due to their compact size and ease of use.

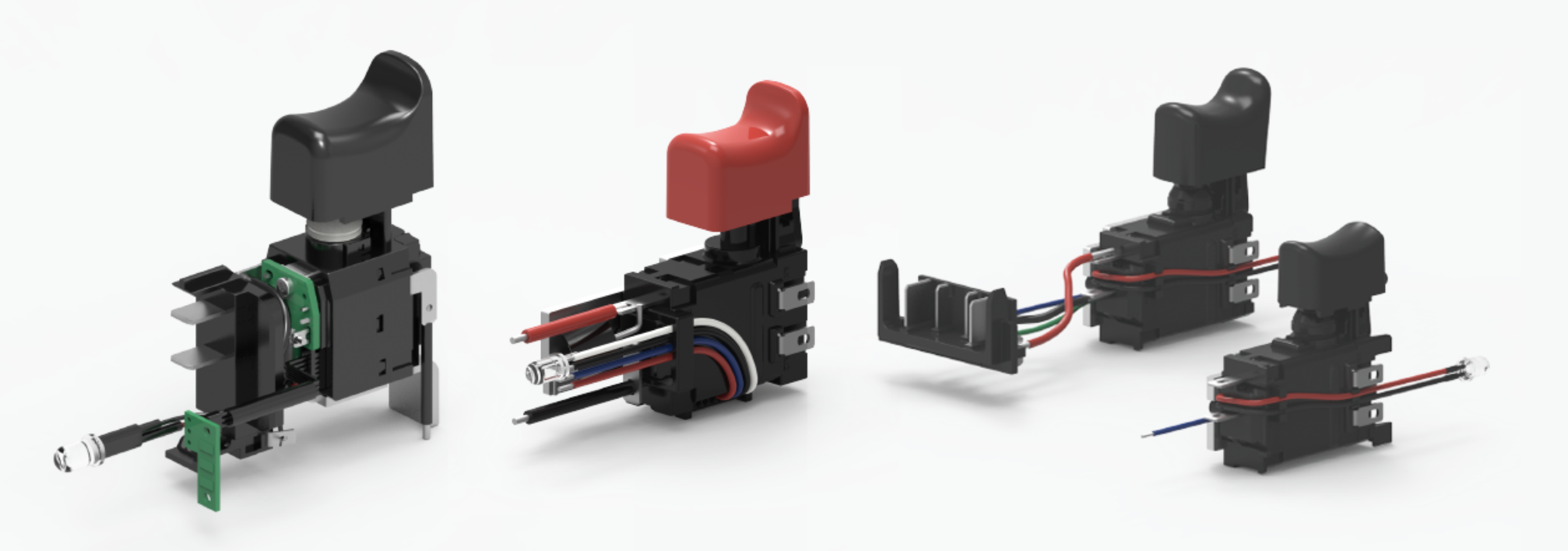

These switches typically consist of a contact block, actuator, and housing, which work together to control the flow of electricity in the tool.

Importance of understanding power tool switches

The proper functioning of power tool switches is crucial for the safety of users, as an estimated 30,000 injuries occur each year due to malfunctioning switches. Understanding the inner workings of a push button power tool switch can help individuals identify potential issues and prevent accidents from happening.

Here are three reasons why it is important to gain knowledge about these switches:

- Safety: The primary reason for understanding power tool switches is safety. A malfunctioning switch can lead to serious injuries or even fatalities. Having a clear understanding of how these devices work will enable users to identify any issues before they become dangerous.

- Circuits: Push button power tool switches form part of an electrical circuit that supplies power to various tools and machines. In order for these circuits to function correctly, the switch must be in good working condition.

- Applications: Knowledge about power tool switches also helps individuals understand their applications better. Different types of switches are used in different devices and knowing what type of switch is used in a particular device can help troubleshoot problems and make repairs more efficiently.

Having a comprehensive understanding of push button power tool switches is essential for maintaining safety while using these devices, ensuring proper functioning circuits, and identifying potential issues before they result in harm or damage to equipment.

Push button power tool switches are critical components of electrical equipment that enable users to turn the device on and off with ease. These switches are commonly found in drills, saws, grinders, sanders, and other power tools used for various construction and DIY projects.

Manufacturers design these switches to withstand frequent use and harsh working conditions in factories or job sites. These push button power tool switches undergo rigorous testing before leaving the factory to ensure their proper operation.

Suppliers need to follow strict standards set by regulatory bodies such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association) to guarantee the safety of electrical devices.

It is crucial for users always to follow the manufacturer’s instructions when handling power tools that contain these switches. Proper maintenance and care can help extend a switch’s lifespan and prevent accidents caused by malfunctioning equipment.

Basics of Push Button Power Tool Switches

This section will discuss the basics of push button power tool switches, including their definition and purpose, components and construction, as well as functionality and operation principles.

A push button power tool switch is a device that controls the flow of electricity to a power tool. It is typically constructed with several components such as contacts, springs, and buttons that work together to allow for easy operation of the switch.

Understanding the functionality and operation principles of these switches is crucial in ensuring safe and efficient use of power tools.

One essential component of a power tool is the push button switch, which serves as an interface between the user and the electrical system that powers the tool. A push button power tool switch is a device designed to make or break an electrical connection within a tool by utilizing an actuator in response to user input. Manufacturers use different materials and designs for these switches, depending on their intended applications and performance requirements.

The main purpose of a push button power tool switch is to control the flow of electricity through electrical circuits within a power tool. This type of switch allows users to easily turn on or off their tools without having to unplug them from the source. The actuator mechanism can be made from various materials such as plastic, metal or rubber, which are selected based on factors like durability, ease of use, and ergonomics.

Additionally, manufacturers must consider other design features such as the shape, size, and position of the switch about other components to optimize its functionality.

Components and construction of a typical switch

The construction of a typical push button power tool switch comprises several essential components that work together to make or break an electrical connection. The switch mechanism consists of the button, which is usually made of plastic and has a spring-loaded plunger underneath it. When the button is pressed, the plunger moves downwards, completing the electrical circuit and allowing current to flow through the tool.

Tactile switches are used in many push button power tool switches as they provide feedback to users when pressing or releasing the button. These switches have a small metal dome underneath them that collapses when pressure is applied, producing a distinctive clicking sound and tactile sensation. Other components include wires, connectors, resistors, capacitors and diodes that regulate voltage levels and protect against overloads or short circuits. Overall, understanding how these various components work together allows us to appreciate the complexity involved in creating even seemingly simple tools like push button power tools switches.

| Components | Function |

|---|---|

| Button | Pressed by user to complete circuit |

| Plunger | Spring-loaded component that moves with button press |

| Tactile switch | Provides feedback via sound and tactile sensation |

| Wires | Convey electricity from source to load |

| Connectors | Join different parts of circuit together |

| Resistors | Regulate voltage levels |

| Capacitors | Store electric charge temporarily |

| Diodes | Allow current flow in one direction only |

Functionality and operation principles

By delving into the intricate interplay of various electronic components, we can unravel the complex functionality and operational principles that underlie the seamless operation of a push button power tool switch.

A push button power tool switch is essentially an electric circuit that is designed to control the flow of electricity through a power tool. The functionality and operation principles of such a switch are determined by its specific construction, which may include both mechanical switches and electronic switches.

The main function of a push button power tool switch is to provide an efficient means for turning on or off a power tool with minimal effort. When the switch is activated by pressing the button, it closes an electrical circuit that allows electricity to flow through the device. Conversely, when the button is released, it opens up this circuit and stops the flow of electricity.

The actual mechanism involved in this process varies from one switch to another but generally involves some form of contact between two conductive materials that allow or prevent electrical current from flowing through them.

Understanding these basic principles can help users troubleshoot problems with their push button power tool switches and ensure reliable performance over time.

Types of Push Button Power Tool Switches

This section will discuss the various types of push button power tool switches.

Momentary switches are commonly used in power tools that require a brief burst of energy, such as drills or saws.

Toggle switches are useful for maintaining a specific setting, such as the speed of a drill, while rocker switches provide an easy on/off switch for various applications.

Finally, selector switches enable users to choose between multiple settings and functions within the same tool.

Understanding these different switch options can help users select the best option for their power tools based on their specific needs and intended use.

Momentary switches:Explanation and applications

Momentary switches, also known as push-to-make switches, are commonly used in power tools to activate the motor only for as long as the button is held down. These types of switches are often preferred over other types because they provide better control and safety when using power tools. When compared to a toggle switch that remains in either an on or off position until manually switched back, momentary switches allow for more precise control of the tool’s operation.

In terms of industrial applications, momentary switches can be found in a wide range of machinery and equipment where precision control is essential. For example, some electromagnetic push button switch models incorporate a momentary action design that enables the user to activate or deactivate certain functions with just a brief press. Weup push button power tool switch manufacturer offers different types of momentary switches depending on their intended application which includes double-pole single-throw (DPST), double-pole double-throw (DPDT), and single-pole double-throw (SPDT) configurations. Overall, understanding the different types of switches available for use in power tools allows users to select the best type suited for their specific needs and preferences.

| Type | Configuration | Function |

|---|---|---|

| DPST | Double-Pole Single-Throw | Controls two independent circuits with one ON-OFF switch |

| DPDT | Double-Pole Double-Throw | Controls two independent circuits with two ON-OFF positions |

| SPDT | Single-Pole Double-Throw | Controls one circuit with two possible connections: ON or OFF |

Toggle switches:Explanation and applications

Toggle switches are electromechanical devices that are commonly used in various electronic and electrical applications due to their ability to maintain a stable state until manually switched. They function by allowing or interrupting the flow of an electric current through mechanical movement, which can be achieved using different mechanisms such as flipping, rocking, or sliding the switch.

Toggle switches have two positions: on and off, with some models offering multiple poles for more complex control circuits. They are typically made of durable materials such as metal or plastic and come in different sizes and shapes depending on their intended use.

Push button power tool switches are one example of toggle switches used extensively in the industrial sector. These switches allow users to turn power tools on and off easily by pressing a button that mechanically activates the switch mechanism inside. The push button itself is designed to withstand frequent use and possible exposure to dust, heat, or moisture while maintaining a reliable connection with the electrical circuit.

Additionally, some push button power tool switches include safety features such as accidental activation prevention or overload protection that enhance their usability and safety. Overall, toggle switches play a crucial role in controlling electrical devices across various sectors due to their simplicity, versatility, and reliability.

Rocker switches: Explanation and applications

Rocker switches, a type of electromechanical device, are widely used in various industries due to their sturdy construction and ease of use. They are commonly found in power tools, home appliances, and automotive applications.

The switch consists of a lever that rocks back and forth to connect or disconnect the circuit. This motion allows for easy control with one hand without having to keep pressure on the switch.

The push button power tool switch is a popular application for rocker switches. Manufacturers offer different variations of the rocker switch depending on the specifications required by the product they are intended for.

Switches can be designed with illuminated indicators, multiple positions, or sealed enclosures to protect against dust and moisture. Suppliers must consider these requirements when selecting the appropriate switch for their product.

Rocker switches are versatile and reliable components that provide efficient control over electrical circuits in various industrial settings.

Selector switches: Explanation and applications

Selector switches are electromechanical devices that allow for the selection of different positions or functions within a circuit. They are commonly used in electronics and electrical equipment, such as push button power tool switches. Selector switches come in various types, including rotary and toggle switches, which differ in the way they function.

A selector switch is an electrical switch that controls the flow of current to different circuits. It consists of a rotating knob or lever that can be turned to select one of several independent circuits. Depending on its design, it may have two or more positions with each position corresponding to a particular circuit configuration.

Selector switches play a crucial role in electronic circuits by enabling users to control different functions without having to rewire the entire system manually.

Working Principles Behind Push Button Power Tool Switches

This Subtopic delves into the working principles behind push button power tool switches. The discussion will cover the mechanical operation of these switches, which involves the movement and interaction of their internal components.

Furthermore, we will explore their electrical circuitry, which is responsible for controlling the flow of electric current to the motor.

Additionally, we will examine safety mechanisms that are typically incorporated into push button power tool switches to prevent accidental activation and ensure user safety.

Mechanical operation:

This section focuses on the mechanical operation of push button power tool switches. It involves a detailed description of the various mechanical elements involved, such as springs, levers, and other components that enable the switch to function properly.

Additionally, the discussion will also cover how pressing the button triggers these mechanisms and initiates the device’s activation process.

Description of mechanical elements involved (springs, levers, etc.)

The mechanical elements involved in the push button power tool switch include a compression spring, a flat spring, and a lever that actuates the contact mechanism. These components work together to enable the switch to function properly.

The compression spring is responsible for providing the necessary force to keep the contacts closed when no pressure is applied to the button. Meanwhile, the flat spring works in conjunction with the compression spring by providing additional support and stability to ensure that there are no accidental disconnects during use.

The lever, on the other hand, acts as a bridge between these springs and the contact mechanism itself by transmitting pressure from the user’s finger into an electrical signal that activates or deactivates power flow through wires connected to various tools or machines.

Overall, understanding these mechanical elements is essential for anyone interested in learning about construction of switches or switch components as well as those who want to troubleshoot potential issues with their push button power tool switches.

Depicting the interplay between the compression spring, flat spring, and lever as a chain reaction of physical forces that ultimately triggers the contact mechanism provides insight into how pressing the button activates the power tool switch.

When a user applies pressure on the push button of a power tool switch, it causes the compression spring to compress and store potential energy.

This compressed spring pushes down on a small lever which has an attached flat spring located underneath it.

The flat spring then flexes upwards and presses against another lever that is responsible for completing an electrical circuit within the switch.

Once this circuit is complete, electricity can flow through and activate the motor to power up the tool.

Overall, this depiction highlights how seemingly simple mechanical elements are carefully arranged to create a complex yet effective system for powering up push button power tools.

Electrical circuitry:

This section will provide an overview of the electrical connections within a push button power tool switch. It will also demonstrate how the switch’s state controls the flow of current in the circuit.

An understanding of these key points is essential for anyone working with power tools to ensure safe and efficient use.

Overview of electrical connections in the switch

Examining the electrical connections within the push button power tool switch reveals the complex network of components that enable its operation.

The wires are responsible for transmitting voltage throughout the system, while electromagnetic switches control the flow of electricity to various parts of the circuit board.

The circuit board itself is a critical component, providing a platform upon which all other elements can be connected and controlled.

By default, this circuit board forms a complete circuit when everything is in place, allowing for seamless functionality when activated by the user.

Understanding these electrical connections is essential for troubleshooting and repairing any issues with a push button power tool switch.

Demonstration of how current flow is controlled by the switch’s state

The state of the switch is responsible for controlling the flow of current within the electrical system. Understanding how a push button power tool switch operates can help prevent equipment failure and ensure that electrical equipment meets performance specifications.

The following subtopics demonstrate how current flows through a circuit and how it is controlled by the switch’s state:

- Current Circuit: A closed loop path where electricity can flow from a power source to an appliance or device.

- Equipment Failure: Incorrect operation of the switch can cause damage to electrical equipment leading to premature failure.

- Flow of Electricity: The flow of electrons between terminals in a circuit determines whether or not an electric current exists and if so, its magnitude. By manipulating this flow, switches control the on/off status of circuits, making them essential components in any electrical system.

Safety mechanisms:

The discussion on safety mechanisms in push button power tools centers around the built-in safety features, such as the deadman’s switch.

These safety mechanisms are crucial for ensuring user safety and preventing accidents during operation.

Proper design is also critical to ensure that these safety features function effectively and prevent potential hazards.

Discussion on built-in safety features (e.g., deadman’s switch)

One notable safety feature of push button power tool switches is the deadman’s switch, which automatically turns off the tool when pressure on the button is released. This feature helps prevent accidents by ensuring that the tool stops running if it falls out of a user’s hand or if they lose control for any reason.

The deadman’s switch works by controlling electrical contacts within the switch itself, and is an important component of any well-designed power tool. It is also important to note that, like all safety features, its performance over time may be impacted by wear and tear or lack of maintenance.

Therefore, users should take care to regularly inspect their tools and ensure that all safety mechanisms are functioning as intended in order to maintain a high level of protection while using power tools.

Importance of proper design for user safety

Properly designed power tools prioritize user safety by incorporating features that mitigate potential hazards. This is especially important when it comes to the design of push button power tool switches, as they are often the primary point of interaction between users and their tools. Manufacturers, factories, and suppliers must take into consideration both the safety benefits and concerns of their designs in order to reduce potential safety risks for users. One way to ensure proper design is through adherence to established industry standards such as those set forth by OSHA or ANSI. Additionally, manufacturers should conduct rigorous testing on their products before releasing them to market in order to identify any potential safety issues early on. By prioritizing user safety during the design process, push button power tool switch manufacturers can help ensure that their products are reliable and safe for use by professionals and DIY enthusiasts alike.

| Safety Benefits | Safety Concerns |

|---|---|

| Prevents accidental start-ups | Risk of finger/hand injury |

| Allows for easy on/off control | Risk of electrical shock |

| Can be designed with deadman’s switch feature | Malfunctioning or faulty switches |

| Provides added protection against unauthorized use | Possibility of switch failure or damage over time |

Troubleshooting Common Issues with Push Button Power Tool Switches

This section will discuss the common issues that occur with push button power tool switches and how to troubleshoot them. Understanding the common problems and their underlying causes is crucial for effective diagnosis techniques.

Additionally, this section will provide tips on repairs and maintenance to ensure that these power tools function optimally.

Understanding common problems:

This section will discuss the common problems that can arise with push button power tool switches. These malfunctions include button sticking, lack of response, and other issues that may prevent the switch from functioning as intended.

By identifying these typical malfunctions, users can better troubleshoot and repair their power tools to ensure optimal performance.

Malfunctions in push button power tool switches, such as sticking or lack of response, can cause frustration and hinder productivity for the user. These malfunctions are often caused by issues with the inner workings of the switch, including problems with physical contact between the switch components.

Some typical malfunctions that users may encounter include buttons that stick or fail to respond when pressed, switches that only work intermittently or require excessive force to operate, and switches that fail completely and do not respond at all.

To help prevent these issues from occurring, it is important to understand how push button power tool switches function and how they can be properly maintained. By keeping the switch components clean and free of debris, checking for loose connections, and replacing worn or damaged parts as needed, users can help ensure that their tools continue to function reliably over time.

Diagnosis techniques:

This section will focus on diagnosis techniques for push button power tool switch issues. It will provide a step-by-step guide to assessing problems with the switch, including how to determine if the issue is related to the switch itself or another component of the tool.

Step-by-step guide to assessing issues with the switch

To properly perform a preliminary push button power tool switch diagnosis, proceed through the following steps systematically.

Firstly, check for any safety concerns such as exposed wires or loose connections.

Secondly, test the performance of the switch by checking if it is responsive and consistent when pressed.

Finally, examine individual components such as switch contacts to identify any signs of wear or damage.

It is important to regularly maintain power tool switches to prevent performance issues and ensure safe operation. Some maintenance tips may include cleaning the switch contacts with a fine-grit sandpaper and checking for any loose screws or connections.

By following these steps, one can accurately diagnose issues with their push button power tool switch and take appropriate actions for repair or replacement of faulty components.

Repairs and maintenance tips:

This section will focus on repairs and maintenance tips for push button power tool switches. In particular, we will discuss suggestions on how to fix or replace faulty components.

These tips may include guidance on identifying the source of the problem, selecting appropriate replacement parts, and executing repairs safely and effectively.

Suggestions on how to fix or replace faulty components

One possible solution to address faulty components in push button power tool switches is to identify and replace the specific faulty component, such as a worn-out contact or a malfunctioning capacitor.

This can be done by first understanding the inner workings of the switch, including how it is wired and what components are involved in its functioning.

Once identified, the faulty component can be replaced with a new one that matches the specifications of the original part.

It may also be necessary to clean or adjust other parts of the switch, such as contacts or springs, to ensure proper operation.

Additionally, regular maintenance tips such as cleaning and lubricating the switch can help prevent future issues with components and prolong its lifespan.

FAQs: Frequently Asked Questions

The proper selection of a push button power tool switch is essential for the efficient and safe operation of power tools. Factors such as the voltage, current rating, and compatibility with specific brands/models need to be considered when choosing a switch.

In case of a faulty switch, it is possible to replace it yourself, but certain safety precautions must be taken to avoid accidents. Additionally, the lifespan of push button power tool switches varies depending on their usage and quality.

To select the appropriate push button power tool switch for specific needs, it is essential to consider factors such as current rating, contact configuration, and actuator style; like a compass guiding a traveler on their journey.

The current rating of a switch refers to the amount of electrical current that can flow through it without causing damage or malfunction. It is crucial to choose a switch with an appropriate current rating for the intended application.

Contact configuration determines how many circuits can be controlled by the switch and how they are connected. Different types of switches have different contact configurations, so selecting the right one is essential in achieving optimal performance.

Another important factor to consider when choosing a push button power tool switch is actuator style. This refers to the mechanism used to activate or deactivate the switch. Different styles include flush buttons, mushroom knobs, and rocker switches among others.

Choosing an appropriate actuator style depends on factors such as ergonomics, ease of use, and aesthetics. By considering all these factors carefully before purchasing from a push button power tool switch China manufacturer or supplier, one can ensure that they select switches that will provide optimal performance for their intended application while avoiding diminished performance caused by using inappropriate switches.

Can I replace a faulty power tool switch myself?

After choosing the right push button power tool switch for your needs, it is important to know how to replace a faulty one. Fortunately, replacing a power tool switch is relatively easy and can be done by most people with basic DIY skills. However, before attempting to replace the switch yourself, it is important to ensure that you have the correct replacement part.

When searching for a replacement push button power tool switch, consider looking for a China manufacturer, factory or supplier. As the world’s largest manufacturing hub, China offers a wide range of high-quality and affordable options.

Once you have obtained the correct replacement part, you can then proceed with replacing the faulty switch. To do this, simply remove the old switch and install the new one following manufacturer instructions carefully. Remember to always prioritize safety when working on electrical equipment and tools!

What safety precautions should I take when working with power tool switches?

Prioritizing safety measures when handling electrical equipment, including power tool switches, is crucial to avoid accidents and injuries. The push button switch, for instance, is a common type of power tool switch that requires proper handling. This type of switch operates by pressing a button that completes the circuit and activates the motor.

To ensure efficient operation and prevent potential safety hazards, it is important to follow safety regulations such as wearing protective gear like gloves and goggles when operating tools with push button switches.

In addition to following safety regulations, maintenance frequency also plays a vital role in ensuring safe use of power switches. Regular inspection of the switches can help detect any potential defects or damages that may cause electrical hazards. It is also important to ensure that all connections are tight and secure before using the tool.

By prioritizing these safety precautions when working with power tool switches, users can reduce the risk of accidents and maintain effective operation of their equipment over time.

Are power tool switches universal or specific to certain brands/models?

Power tool switches are not universal and vary in their compatibility. In fact, push button switches can be unique to specific brands or models, making it crucial for users to do their research and ensure they have the correct switch for their equipment.

While traditional switches may seem interchangeable, even within a single brand or model line, differences in product details like current ratings can mean that using the wrong switch could damage your power tool or even pose a safety hazard.

When selecting a power button switch, it is important to take into account factors such as voltage and amperage requirements, as well as any specific features or functions required by your equipment.

Additionally, when replacing an existing switch with a new one of the same type, it is essential to match the exact specifications of the original part to avoid compatibility issues.

By being diligent about researching and selecting the appropriate switch for your power tools, you can help ensure both optimal performance and safe operation.

The lifespan of a typical push button switch used in various industrial and household applications can vary depending on several factors. Pushbutton switches are mechanical devices that use electrical actuators to open or close a circuit. Over time, the movable contact inside the switch can wear out, causing the switch to fail. This can be accelerated by frequent use, exposure to harsh environments, or poor maintenance.

One way to extend the lifespan of a push button switch is to use high-quality materials during its manufacture. High-quality materials can withstand wear and tear better than low-quality ones, reducing maintenance costs and increasing reliability. Another factor that affects the lifespan of a push button switch is the design of its stationary contacts. If they are made from soft metals such as copper or tin, they may become deformed over time due to repeated contact with the movable contact. In contrast, hard metals such as silver or gold may last longer because they resist deformation better.

Overall, proper maintenance and attention to quality during manufacturing can help prolong the life of push button switches in power tools and other applications.

It is possible to modify a push button power tool switch to have additional functions. However, the specific modifications that can be made will depend on the design and capabilities of the switch. Before attempting any modifications, it is important to thoroughly understand the inner workings of the switch and ensure that any changes do not compromise its safety or performance.

Additionally, modifications may void any warranties or certifications associated with the tool. It is recommended to consult with a professional or manufacturer before making any alterations to a power tool switch.

Push button power tool switches are commonly used in a variety of power tools, ranging from drills to saws. These switches are designed to provide a quick and easy way for users to turn the tool on and off. They can be used with both corded and cordless tools, making them a versatile option for those working in different environments.

However, it is important to note that not all power tools may be compatible with push button switches due to differences in design or functionality. It is always recommended to consult the manufacturer’s instructions before using any switch with a power tool.

Overall, push button power tool switches can offer convenience and ease of use but must be chosen carefully based on the specific needs of the user and their power tool. Using a metaphorical reference, these buttons can be likened to keys that open up doors; unlocking the full potential of your equipment when utilized properly.

Conclusion

In conclusion, push button power tool switches are an essential component of power tools that enable users to turn them on and off. Understanding the basics and types of push button power tool switches is crucial for selecting and maintaining them.

The working principles behind these switches involve the use of mechanical contacts that create a circuit when pressed. However, common issues such as overheating or malfunctioning can occur due to various reasons such as faulty wiring or dirty contacts. Therefore, it is important to troubleshoot these issues by checking the wiring connections and cleaning the contacts regularly.

Overall, push button power tool switches play a critical role in ensuring safe and efficient operation of power tools. As Thomas Edison once said, ‘The three great essentials to achieve anything worthwhile are hard work, stick-to-itiveness, and common sense.’ These words apply well in this context – using common sense by understanding how push button power tool switches work will ensure their efficient use and longevity.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd