Trigger switches are a crucial component in power tools, playing a pivotal role in user safety and control. Let’s delve into how these switches work, their types, and the key considerations for their design and functionality.

How Trigger Switches Work

Trigger switches in power tools are essentially electric switches that control the tool’s motor. When the trigger is pressed, it completes an electrical circuit that allows current to flow to the motor, activating the tool. Releasing the trigger breaks the circuit, stopping the flow of electricity and halting the tool. This simple mechanism is fundamental for precision and safety, allowing for immediate stoppage of the tool when necessary.

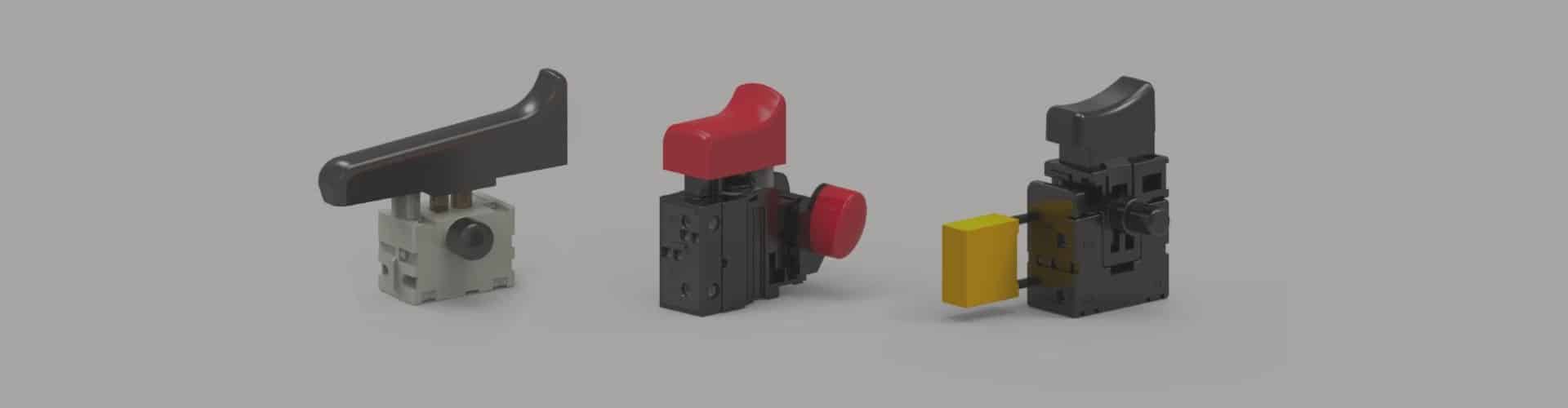

Types of Trigger Switches

- Variable Speed Trigger Switches: These are commonly found in drills and allow the operator to control the speed of the tool by varying the pressure on the trigger. The harder the trigger is pressed, the faster the tool operates. This is particularly useful for tasks that require different speeds for different stages or materials.

- Lock-On Trigger Switches: Used in tools that are operated for extended periods, like angle grinders and circular saws, lock-on triggers include a mechanism to keep the tool running without continuous pressure on the trigger. This reduces operator fatigue but requires a reliable safety mechanism to prevent accidental activation.

- Safety Trigger Switches: To enhance safety, these switches require a two-step process to activate the tool—typically involving a safety catch or a dual-button mechanism that prevents inadvertent operation.

Design and Functional Considerations

Ergonomics: The design of a trigger switch must ensure comfort and ease of use, minimizing strain on the user’s hand and fingers, especially during prolonged use. Ergonomically designed triggers help prevent fatigue and repetitive strain injuries.

Durability: Trigger switches are subject to constant mechanical and electrical wear. High-quality materials and robust construction are essential to withstand the rigors of heavy usage and the harsh environments where power tools are often used.

Safety Features: Safety is paramount in the design of trigger switches. Features like quick-stop mechanisms, which halt the tool almost immediately when the trigger is released, and safety locks that prevent accidental start-up, are critical for user protection.

Electrical Specifications: Trigger switches must be designed to handle the specific electrical requirements of the tool, such as voltage, current, and type of current (AC or DC). They must also be insulated to protect the user from electrical shock.

Future Developments

The ongoing evolution of trigger switches in power tools focuses on enhancing user safety, improving durability, and integrating smart technologies. Innovations like wireless controls and programmable settings are being explored to offer more versatility and safer, more efficient operation.

In summary, trigger switches are vital for the effective and safe operation of power tools. As technology advances, we can anticipate even more sophisticated designs that enhance the user experience while maintaining rigorous safety standards.